The events we are truly interested in are the "seated" valve events. The point where the valves just lift-off the seats or just touch-down on the seats. In lieu of that information we use advertised duration, because its the best information we have, i.e. its closer to seated valve events than duration at 0.050. Duration at 0.050 has its uses too, but not when we are trying to define the characteristics of an engine's power band based on seated valve events.

You'll need 4 pieces of information, usually available

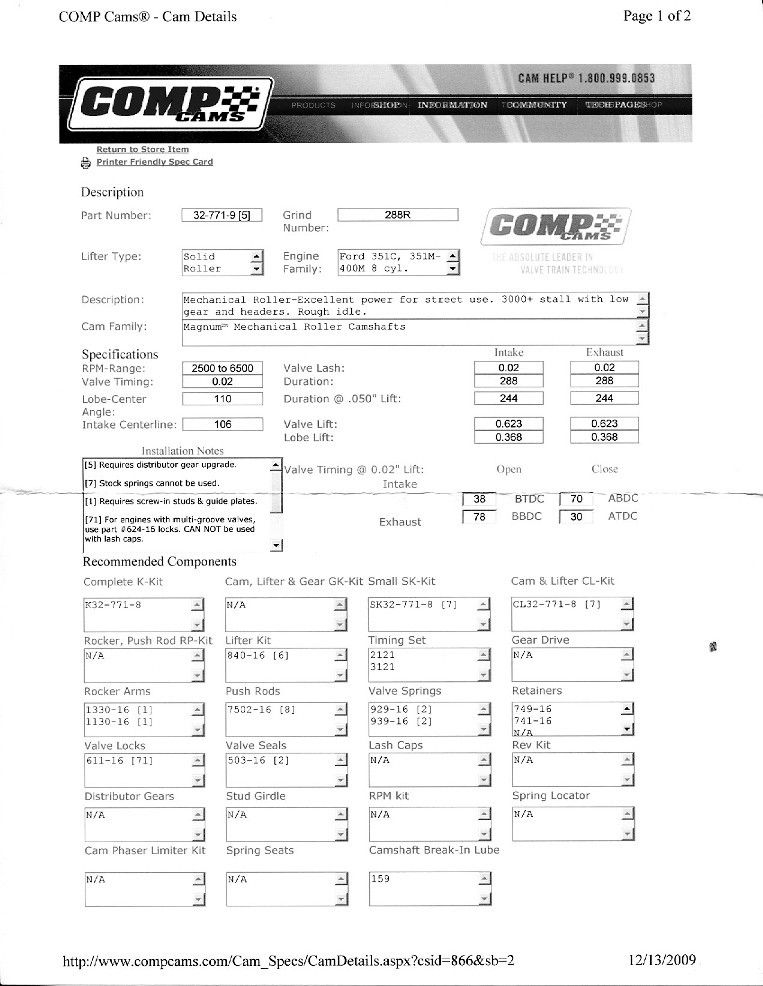

- Advertised Intake Duration

- Advertised Exhaust Duration

- LSA

- Intake Centerline

_________________________________________________________________________

Valve Events:

EVO = (Advertised Exhaust Duration ÷ 2) – (180 – Exhaust Center Line)

IVO = (Advertised Intake Duration ÷ 2) – Intake Center Line

Overlap = IVO + EVC

Overlap = Average Advertised Duration – (LSA x 2)

EVC = (Advertised Exhaust Duration ÷ 2) – Exhaust Center Line

IVC = (Advertised Intake Duration ÷ 2) – (180 – Intake Center Line)

___________________________________________________________________________

Other Terms:

Average Advertised Duration = (Advertised Intake Duration + Advertised Exhaust Duration) ÷ 2

LSA = (Intake Center Line + Exhaust Center Line) ÷ 2

Exhaust Center Line = (LSA x 2) – Intake Center Line

Intake Center Line = (LSA x 2) – Exhaust Center Line

____________________________________________________________________________

One other term I find useful to calculate from time to time is

overall valve event duration which is the total duration in degrees of crankshaft rotation between the moment the exhaust valve begins to open and the moment the intake valve fully closes. Overall valve event duration must encompass at least 510° of crankshaft rotation to make it possible to open the exhaust valve at 80° BBDC and close the intake valve at 70° ABDC. There are two methods to calculate that figure:

Overall valve event duration = EVO + 360° + IVC

or

Overall valve event duration = (Advertised Intake Duration + Advertised Exhaust Duration) – Overlap