Similar cams typically have narrower lobe centers (108° to 112°), more overlap (70° to 85°), and a steeper torque curve ... the stuff drag racers like. The cam I've penned is designed to give the engine a wider flatter torque curve, thus the power is easier to control, and the torque curve is stronger at low rpm for accelerating out of corners. Its a “circuit racing cam tamed for the street”; estimated to produce 435 horsepower peaking at 6400 rpm. It provides a level of performance in terms of horsepower and rpm that is about all the performance the thin wall production block can handle reliably. Unlike all of the other cams within this genre, this cam will also allow the engine to retain good street manners.

I think this would make a really nice cam for a sports car engine. What do you think?

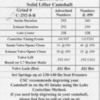

Duration at 0.020 inch tappet lift (advertised) = 277°/282°

Duration at 0.050 inch tappet lift = 242°/246°

Gross valve lift at 1.73:1 rocker arm ratio = 0.588/0.593

Net valve lift at 0.029/0.028 lash = 0.559/0.565

----------------------------------------------

ICL = 109° ATDC ----------(An earlier ICL synchronizes air flow capability more closely with air flow demand and makes more power)

LSA = 114° ----------------(A wider LSA reduces overlap, produces a wider and flatter torque curve; improves controllability.)

Seated Overlap = 51.5° ---(Limiting overlap to 60° or less improves vacuum, idle, low rpm torque and drivability.)

Seated EVO = 80° BBDC --(An earlier EVO compensates for a muffled exhaust, improves idle, extends high rpm power, and reduces pumping losses.)

Seated IVO = 29.5° BTDC (Limiting the IVO to 30° or less improves vacuum, idle, low rpm torque and drivability.)

Seated IVC = 67.5° ABDC (A later IVC lowers the DCR, requires a higher SCR; can lead to reversion at idle.)

-G