quote:

Originally posted by Cowboy from Hell:

Doug, those are Scott Cooks heads, they have high swirl combustion chambers. They can run 11:1 on the street with pump gas OK. 28 degrees ignition is full advance with those heads!

Corey, comparing two random engines proves nothing. To do a comparison between parts you need to be swapping them on the same short block, changing only one thing at a time, the parts in question, whilst other important things like cams, pistons, carbs remain the same.

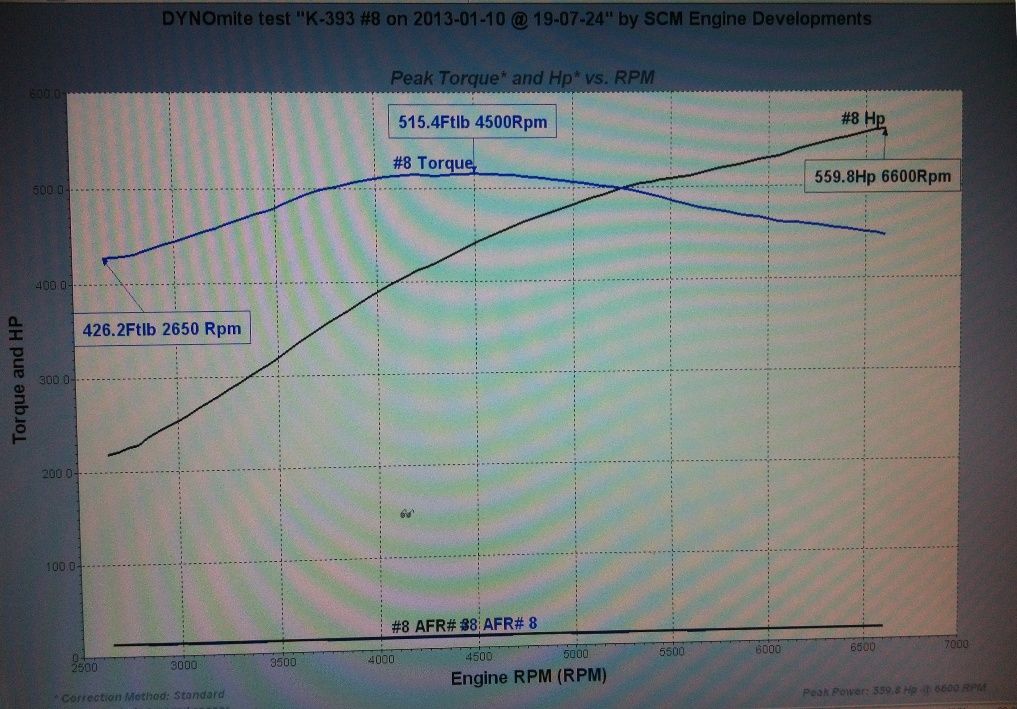

You're taking the thread in the wrong direction. My point is admiration of that flat torque curve, not a head comparison. Its OK for me to admire the torque curve of that motor, it doesn't detract from TFS heads in any way. You're welcome to like TFS heads. I don't dislike them. But your post seems quite rude to me. What is your point, what are you trying to accomplish. Do you insinuate nobody should purchase SCM heads?

George, Scotts heads are beautiful. I'm not insinuating anything negative about them.

I think Corey's post is fair. I think there is going to be a similarity between all of them.

Octane rating of gasoline is in effect a statement of the presure the atomized fuel will withstand in the combustion chamber without detonating without a spark. Also know as dieseling.

With a static compression ration of 11:1, there is no possible way 93 pump octane can run without detonating virtually at idle, or just off of it, without 1) limiting the amount of total ignition advance 2) timing the exhaust to fool the engine and leave the exhaust valve open long enough to blow some of the combustion pressure out of the exhaust 3) limiting the rate of ignition advance.

Apparently Scotts test is a testiment to finding the balance between, pump gas, cam timing, and ignition timing.

There are lots of magazine dyno tests where the adjustment to detonation on the dyno with pump gas is to reduce total advance to that number, 28 degrees.

Big block Chevys and Mopars like that number too.

Increasing total advance increases combustion pressure similarly to razing static compression ratios. You need more octane, i.e., less sensativity to detonation in order to do that. Todays pump gas just won't cut it.

In fact I even tried the Sunoco 102 unleaded Racing gas and it still was useless. 106 is the only thing that is going to work, which is fine if I want to pay $7.50 a gallon for it and tow a tanker of it behind me with it.

You can swirl all the mixture you want around in those heads and that isn't going to reduce the presure in the combustion chamber.

It is cam timing, ignition timing, and static compression ratio.

Put Sunoco 106 racing gas in that engine on the dyno, retime it to where it should be, 34-35 degrees and you are going to pick up 100 hp.

The point is, 28 degrees total timing, is a dyno trick to make a high compression engine run on pump gas.

The better solution is to run a compression ration of around 10:1 with those heads, or any heads, run full advance of 34-36. Slow the advance down so it isn't all in to around 5,000 engine rpm.

That would be realistic and wouldn't be a dyno trick to make your product look like something that it isn't.

Furthermore, limiting to a total of 28 degrees effects adversely the response or crispness of an engine. It really should only be done as a last resort.

Been there, done that. Maybe the Aussie's think because they are upside down, then the laws of Physics don't apply to them, I don't know?

. This is also from a 394 and yes the RPM is correct.

. This is also from a 394 and yes the RPM is correct.