Finishing up the deck lid metal work:

Finally getting all the old paint off reveals a very clean original piece.

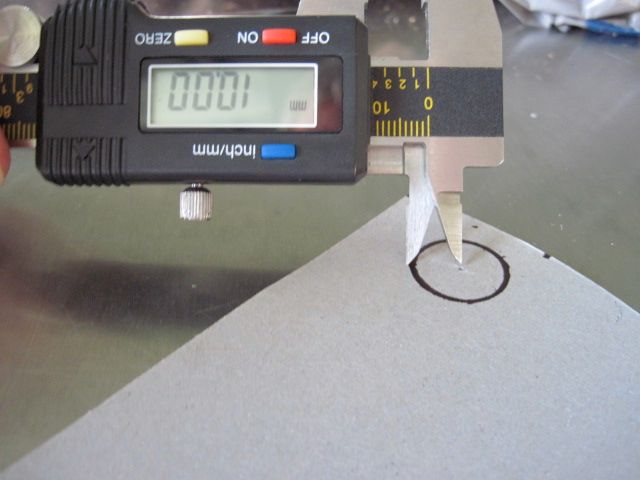

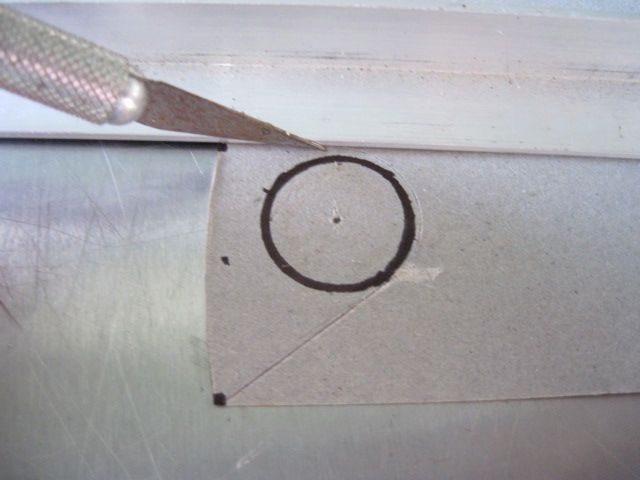

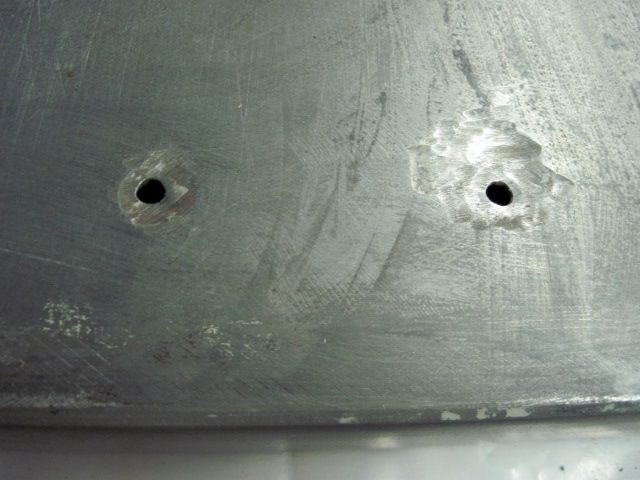

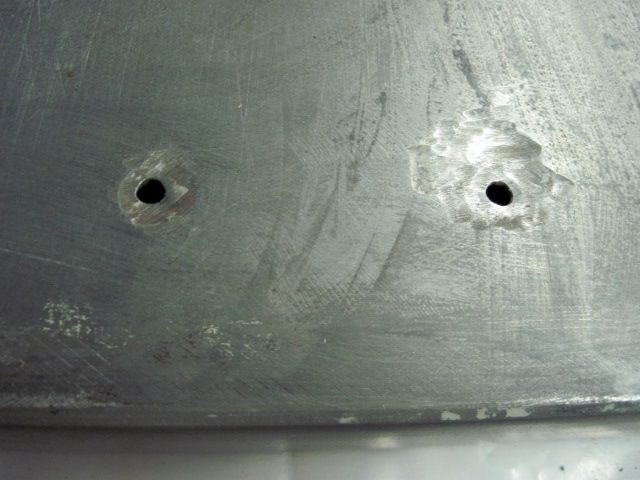

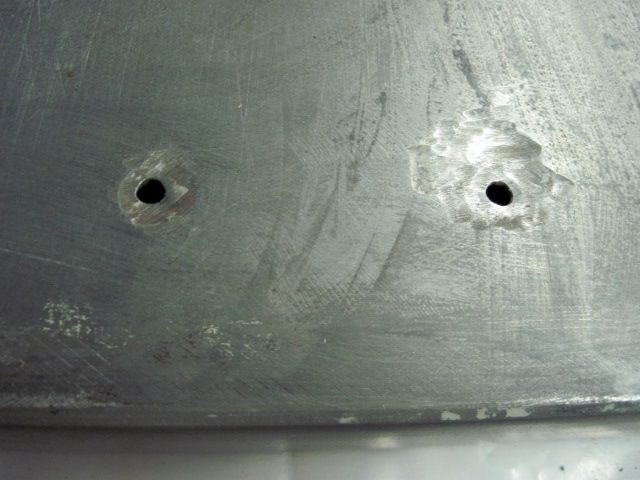

The "Power by Ford" emblem mount holes

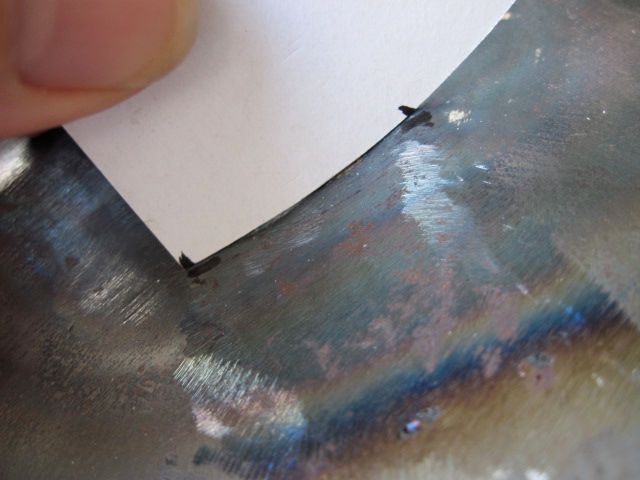

And a couple more on the left rear upper surface

Funny, there were no similar holes on the right side; like someone started to mount a wing and gave up. Strange. All these I welded shut.

These recesses are a bear to get paint out of:

You can't sand blast in there - it just blasts right back out at you. Too small for a power tool. Just paint stripper and scraping by hand; sometimes using a mirror to see what I am doing. Lots more work that it's really worth.

Finally ready for the first coat of primer, and my first OOPS:

Do NOT mix epoxy paint in a plastic cup.

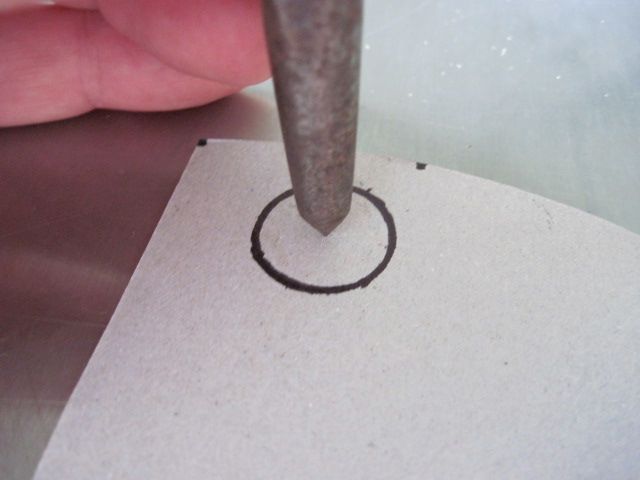

OOPS #2 - same day:

Do NOT drop the trouble light into freshly applied paint deep in one of the least accessible places on the car. (see above).

I reached in with a needle nose pliers to get the big pieces, and put double sided sticky tape on the end of a ruler to get smaller bits. After the paint was dry, I scraped out everything I could, and applied another coat of paint to cover anything I might have missed. UGH - several hours of extra work.

I brush painted in the really hard to reach areas, then sprayed the first over all coat:

My make - shift paint booth did not work very well. It came out OK, but was a pain to set up and tear down. The deck lid is the only piece I did this way. I came up with a much better method later.

This bad boy is heavy, here it goes back on for some test fitting:

I sanded off most of that first coat; you can see little patches of it in this photo:

Thought I had a pic of it all done - but maybe not. I'll take one next time I get it down.

Rodney