The ONLY sure way to determine 100% release of the clutch disc is to use feeler gauges and measure the clearance.

I can't remember exactly at this moment the differences in the requirements but the three finger requires less clearance than the diaphragm does.

I think it is .035" for the three finger and .045 for the diaphragm.

That's all that matters. Leave the clutch pedal alone. It winds up where it winds up.

The only significance to that is that at somewhere less than full travel you have full release.

Also consider that these nice thick plush floor mats have a very significant thickness to them and reduce the amount of travel your pedal has to release the clutch fully. All this issue could simply be that.

As BW says, everything is so freakin' tight with adjustment on the Pantera for clearance, a simple change like the disc thickness or a change to a disc with more Marcel can change everything.

The original Pantera disc had the Marcel removed to add clutch travel to make it work.

If there was an original mistake in the calculation for the necessary clutch travel then it was likely for Marcel.

It is also possible that the calculation was taken from the GT40 as a race car and it had no Marcel in the disc.

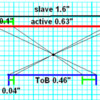

As far as how to adjust the Pantera clutch, block the pedal to the floor, then adjust the slave to give you the clearance with the feeler gauge installed.

The observation port in the bell is put there so you can do this procedure. In fact it is probably the only way to be sure the release clearance is right.

As BW also said, a ceramic throw out bearing is a great idea so that if it happens to be that you are riding a hair on the fingers because that's all the travel you can get, you won't eat up the face of the throwout bearing.

The tips of the fingers are already hardened for this.

You actually need to be really careful with the Centerforce that uses a diaphragm disc because those fingers are not sufficiently hardened to resist wear.

...and not to be argumentative Chris, that isn't my intent but I seem to remember the full new disc thickness as right around 3/8" or .375 to .380 with the micrometer WITH a full Marcel disc.

I don't have an "original" clutch disc here to measure but it would make sense to me that without Marcel it might be right what you said at around .280"?

In my young and wild days as opposed to my old and cranky ones, I seem to remember putting calipers on "worn out discs" and they were at around .320 to.325" left, so bottom line, there isn't a lot of material between full and empty on a disc.

For those who don't know. The wavy line that runs through the center of the disc (arrow pointing to it) is the Marcel spring. It helps push the clutch apart when releasing and was eliminated in the original factory installed disc to gain room for the clutch assembly height.

I don't think that I am having psychotic episodes right now, for one thing no naked waitresses are wiggling their 'goods' and trying to seduce me...but that may not be the determining factor...I don't know...I forgot?