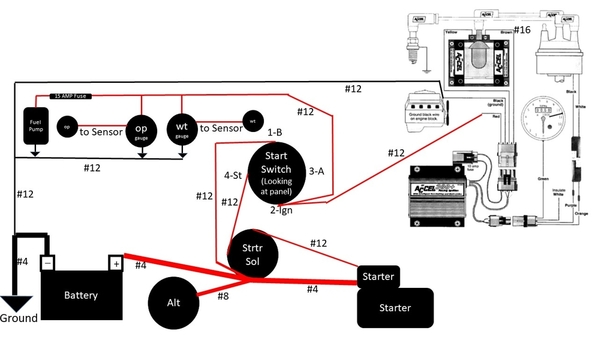

For you folks that are electrical gurus, how does this wiring set up look for a test stand to run Goose engine? The starter, starter solenoid, alternator, battery, oil press sensor, water temp sensor, and ignition system are the components I'll actually install in Goose so thought it would be good idea to test them. I had goose fans/relays/fuses wired in in my first incarnation of this but just decided to put a floor fan in front of radiator when temp gets to 180.

I keep a set of manual gauges for oil and water monitoring..... hook up the coil with a paper clip to power....not really.....but a big wire.....jumper cables to the starter solenoid, some gas in a can and hit it!!!! Make some noise!!!

Drawing looks good with only one question about #12 wire to 1-B on ign switch for alt charge. I would think this connection would be to #2 for the "run" or "ign" mode? Not sure what the #1 terminal is here......

As for the Accel stuff and tach......hafta go with what they recommend in their papers.....

Video at 6????

Steve

Thanx much.

There is no real stock mirror on a Goose....many were shipped here without...and dealers popped whatever they had on a fender or door and away it went......

You might post a pic of the mirror you are dealing with...perhaps then help can be offered....

Glad to see progress!!! I bet you are also!

Steve

4263598 -

https://www.ebay.com/itm/RELE-...p2060353.m1438.l2649

I bought "Itab" made relays, which (like the Carello) are also marked "Torino" and I'd bet were a common manufacturer as the Carello. I did buy a NOS Carello 22.900.000 many months ago, it was very expensive but I was drunk with the find...

The Sipea part numbers for this relay (with metal instead of plastic body) seem to be 5170 and 7810.

Good find!!! I would venture that your theory of manufacturer supplying others is probably not far from truth..... That looks too similar!

I found some Carello relays on some Italian car in the junk yard years back, but found that one was a "NO"= contacts "normally open" and one was "NC"= contacts "normally closed".

Some relays, like the small cube Bosch types may have both options are are great substitutes in a jamb or as spares.... But the Carellos seem to be one or the other!

So, buyers beware!!!!

I like the circuit on the plastic to "explain" how to hook it up!!!

Cheers!

Steve

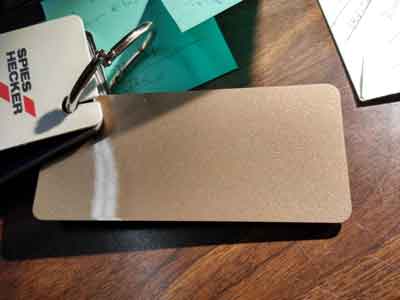

Well, a little movement in the right direction. Almost 4 years since going to paint shop. Car has been red, but original color was copper. New color will be as close as I could get to metallic platinum on the prototype. Attached are samples of the paint selected. Since the prototype's metallic platinum was not one of the original gooses colors, this Porsche color appeared to come the closest.

Attachments

Keep up the good work! A few months ago there was a very original/low mile goose for sale, I believe it was out of Florida. I thought it was the same color as the original prototype, but that was just an assumption. It looked pretty close to your sample chips. Sadly can't locate the ad at the moment.

You know, I remember seeing that car advertised now that you mention it and show the pics. I am guessing that is the color my car was initially (copper). I am really hoping this new color is close to the prototype if not exactly the prototypes color.

Found this on youtube this morning:

https://www.youtube.com/watch?v=5p4JLdDe8SY

The car in this youtube video looks like the folks who restored this car in the 90's were trying to match prototype color as well. This is pretty close to what I'm hoping for.

Goose should be coming back from long paint (in shop since 2015 in the next couple months - I hope!!).

I know I need to rebuild front suspension and steering (as well as rebuilding the rest of the car) . Couldn't find detailed writeups on these items. Anyone have this data?

Thanx

Mark

Others can likely provide better info but here are some off the cuff thoughts;

Inspect front A-Arms for cracks or signs of stress. If they are painted or coated, it may be worth stripping them to reveal the metal. Rear A-arms are known to fail as well.

Make use of the grease fittings to lube up the joints.

Replace shock and spring which can be sourced from PI motorsports. For mine there was some light machining work needed to attach them properly, but nothing major.

Find an alignment shop who is familiar with old Italian cars. Bump steer.

Bushings may be in poor condition. Consider cutting new from Delrin. Actually not certain if Delrin is best for this application but I have found success with it as a bushing material on other cars.

Since it's all apart, you might as well address the rear transmission support. There's a great amount of detail related to that topic on these forums. I won't try to re-hash it here except to say it's important if you'd like the car to handle reasonably.

I know little to nothing about the steering. It sure would be nice if there were a rack with a faster ratio which could be swapped for the slooowww factory rack. One day when the car is more sorted out I'd like to attempt adding an electric power steering 'helper'. They are popular in the offroad world.

Mark, Scifi,

Some observations of mine over the years spent getting our car back on the road....and some efforts of others!

Front A-arms: Your early car likely has "rev-A" lower arms. These have metal strip welded along bottom of tube(s) but stops short of the ball joint cup. This is where they are known for failure...cup busts right off. Rev-B arms used a metal "U" channel about 3/8" or 10mm square which is welded along the bottom at intervals, and extends over the BJ cup area strengthening the whole mess. I had one of each on my car due to accident...welder could only find solid bar to use, but I think "U" style is available if ya look...... (MSC ???)

Front Lower Bushings: Inspect and fab replacements as needed. I put some new ones in.....but they didn't offer much improvement if any, over the old ones! They do need some lube all over everything to prevent squeaks....there are no grease zerks here.....luckily you can just lift the corner of the car to unload the suspension and the two bolts can be removed allowing the lower arm to be dropped for servicing.....doesn't affect any alignment.

Ball Joints: Inspect for blown apart ball joints. Originals appear to be two pieces of stamped steel welded at the edges. You can expect multiple pieces to fall out if you still have originals. New ones are cast units- Fiat 124 uppers if memory serves me. DO NOT grind the a-arm cups to accept new ones...... get the proper ball joints...! They are out there and readily available.

Rear A-arms are a little more beefy- I had no issues with these.... Often bent from idiots raising car with jacks under arms......!

Trans support: Lots said about this, but only one modification I would accept on these cars, which is to add inboard connections for the ladder bar at the top of the shock towers. (Inboard about 5-4" from outer upper shock bolts.) This will "help" prevent catastrophic failure if the shock tower cracks! Don't ask how I know this...... Easy enuf to do.

The bushings at the outer ends of the trans cross member are the same as the stock shock absorber bushings....if you have any good left in them.....but these bushings usually stand up better in the crossmember position! Not sure of availability any longer....you may need to fab something up!

I added a small stiffener bar between the outer mounts of the trans crossmember to prevent "some" amount of frame flex.... I know that other solutions have been suggested for preventing "Z" flexing of the chassis under hard cornering...it's real.....but quite frankly, it's way easier just not to "hard corner".....! After all, you are driving a 401K plan that has performed handsomely over time....no need to trash it senselessly now! IMHO, if you NEED to go hard cornering, buy a different DeTomaso or a late model 5L car and have at it..... Drive your GOose in a gentile and stately manner around curves! ![]() )) You will look fantastic doing it!!!!

)) You will look fantastic doing it!!!!

Steering rack: While the RHD cars allegedly had a swap rack to drop the ratio, I have not heard of any for the LHD Goose. In my experience, after now driving a Pantera for a while, the Goose rack feels very comfortable compared to the lower ratio in the Pantera. Not ideal for close corner fast-slow speed maneuvering, but since you are carving the corners off of your new tires, and stressing all of your frame member attachments, just don't do it. Your car looks fast sitting still....... The higher ratio rack makes the car easier to control in and out of parking spots!

Bump Steer: Ugh. We have one or two members here with extensive frame/steering knowledge that set out on an effort to cure this issue. The results were either epic failure, or "it fixed some of it". The latter required machining of the outer steering rod on the spindle, spacers for the tie rod ends.....and perhaps a little more. More than most would like to undertake....perhaps. Attempts to raise or lower the rack find interference from the frame in every direction! Wholesale redesign of the front frame members required. Not going there!

I would think that when doing close to triple digits on a bumpy road is where bumpsteer would be an issue...and not on smooth roads. So, stay off of bumpy roads when driving fast! Your chassis will love you for it!! ![]() ))

))

Love the car for it's beauty....forgive it for the defects, and "drive around" the bumps!!

Cheers!

Steve

Thanx Steve and SCIFI

Here were the front end 'symptoms' before I took it into paint...wheels splayed out to some extent when steering wheel in normal position, and lots of play in steering wheel...I could move it back and forth from 10 to 2 and the wheels wouldn't move...almost all the rubber boots in the front end need to be replaced (and I'm sure the bushings are right there with them). Any ideas on what the major problems might be?

Since the chassis has everything removed for the paint job, when I get it back is the time to completely take the suspension and steering apart and rebuild to something acceptable to 'drive like a 401k' (I like that Steve). I'll look for all the items the two of you mentioned. Any gotchas on taking the front end apart?

Also Steve, have my 69 Boss 302 motor rebuilt ready to test run and reinstall into the chassis/frame that had been modified back in 1969 (professional job vs hack job) to accomodate the wider heads and sit low in the engine bay to fit comparable to a 289/302. The OEM drv side exhaust manifold is fine and fits perfectly in the modified frame. The OEM pass side exhaust manifold is a franken-manifold since the exit from the manifold had to be relocated low and between the two middle exhaust ports. My options are: take the franken-manifold and have it refreshed to patch cracks on old welds and redo bolt holes, or try to build a set of headers (options being weaving thru frame low or going high like Dick Ruzzin did in his car). What are your thoughts?

Mark

Mark,

Re the "lots of movement" in the steering wheel..... check condition of ragjoint, the tiny (unobtanium unless in Europe) U-joints, and after that, my guess is that it is all in the rack gears. Rack is simple deal.....only two moving parts! Clean and inspect rack and input gear for wear/play.

Front end is pretty easy to take apart. Upper shock bolts can be fun... Upper a-arm bolts could give you pain if they are corroded in place. Clean and grease before assembly..... Nothing really major....not much to it all. If you unload both sides at once, sway bar connections will come apart more easily. Be careful not to damage threads on outer tie rod ends when taking it apart. Use two hammer method to "compress" the steering arm end, to pop the end joint out of the arm. The parts on the steering rack ends to the tie-rods are specially modified parts in some cases. Not "off the shelf"! (This may not apply to late cars)

Boss 302: ......after fighting with the crummy fitment of the headers with my Boss, the raised motor mounts, air cleaners that wouldn't fit, and more..... namely being the 331 5.0L based SBF engine that I put in place(!).... that engine ran SO much better than the Boss......BUT, the Boss had issues due to mod's meant to "de-perform" it to make it more driveable.....which didn't quite work..... It should have ran and performed better!

As for your "franken-manifold".....tough call! I would have offered you my "franken-headers" from my car, BUT, they were 2V port sized...not the 4V that you have! Is there ANY chance that a 70-73 351-4V right hand manifold might be more easily modified and substituted for your chopped up Boss manifold??? If not, I think I might be inclined to go for a new header....with the ugly being the fact that you're not going to find anything out of the box to fit! Although, that said, you could have some luck perhaps, with a set of Pantera headers to start with! I think I have a couple of sets of original exhaust headers with slightly eroded end flange areas (at muffler end) but the top section may serve as something to start with???? May be easier than a flange and a "box-o-curves" kit that you would likely need!

Here are some Pantera headers that I have, some have cracks in all the normal places.....! So good candidates for mod or copy.

Gotta go play plumber...ugh.....!

Attachments

Look, I know I'm being a bud-in-ski here. It seems to me that running a Boss 302 head in a Mangusta isn't worth the effort with the changes you are talking about?

I'm using AFR 1388 heads on my 347 in my 68 GT350. Go and look at the flow numbers on the heads. They out flow stock Boss 302 heads.

They are a direct replacement for the iron 302 J heads once you shave them .024".

That means everything stock Mangusta is going to bolt up to them. You don't need Boss heads. The AFR's are better.

Now if you are going to say the AFR's are modifying the car, what do you call a Boss 302?

OK. Enough of my budding in here. Sorry to interrupt your discussion.

No sweat, am sure you're right. Car had the change made to Boss 302 motor in late 60's. Apparently, it may have been Chicago or Detroit Auto show car (couldn't get this verified). Does kinda make sense since the saying used to be 'race on Sunday sell on Monday'. Anyway, will keep it this way since its been in this configuration since the beginning, and refresh it as close as possible to the way it was in 1969.

For future reference

If you (any member) would like a topic opened, just send me a private message & I'll open it for you.

If there was a universal way to unlock all topics I would, but there are too many to unlock them all one at a time. However I'll gladly unlock them by request.

How exciting!!!! You must be stoked with anticipation!

Well finally a little movement. Attached are the prototype color I am going for and the paint model I received that my Goose will be painted...close but not a perfect match.

After 5 years, positive movement!! Car was completely primed and ready, but they found a 'reaction' between primer and metal so they are stripping it and putting on a different primer. Shooting for paint in attached color in Jul.

Attachments

great color can i ask what it is

That will be awesome. Keep posting pictures as you can! Everyone wants to see it!

Rocky

Tried to find the prototype color in the De Tomaso pallet of colors to match, but it wasn't there. Went thru Ferrari and Maserati colors as well, but didn't find a match. Eventually, the platinum color selected is from a Porsche 911 from a few years back.

Are you going to match the wheels to the car, like the prototype, or use the Argent Silver?

Wheels already one and match those in the prototype pic I included. Believe they are argent silver.

Great color!.....will be SO nice when everything is done, looking forward to more photos as work progresses![]()

Look at https://www.madle.org/ecolsamp.htm.

I think DeTomaso use Glidden Salchi S.p.A. colors for Mangusta.

Congrats, really nice.

SCHWING!!!!!! How exciting!!!! Been a long road!

Steve

Would appreciate someone providing dimensions of battery location so can purchase new battery for Goose. Thanx.

...I can't think of many cars that would ever look good in gold...but it really works on a Goose ! congrats!

The battery is a Group 24F.

I think it is going to truly take on its true glory when assembled and sporting some bright bits, some blacked out bits, and a complementary interior color palette.

have you chosen a wheel color yet?

Larry

Not to second guess Denisc but you may want to double check the dimensions before buying your battery. Mine had odd protrusions at the very bottom, so even though the overall dimensions made sense the battery would not sit flat in the tray. Relocating battery to front would be a big win for weight distribution. Not only does the weight leave the rear, but is added up front. Then again it looks like you are striving for some sense of originality so maybe save that trick for your next Mangusta.

The Goose battery is a 24 series version. The factory used a rubber pad (from Carello!) to set the battery on, which would lift it about 3/16"......but it would be easier to find a "protrusionless" battery!!!

Edit: 12/19 I miss stated above about the Carello battery "pad".... since the Goose battery tray is not solid flat on the bottom but more like "angle-tin" pieces....with a big hole in the middle.

I found "strips of rubber" that fit into the frame bottoms and on the backside of one of the strips I found "Carello"....... probably didn't take pictures......just put it back in place.....!!! Sorry!

Scifi- you are correct......don't go cutting up the Goose!!! Remember when driving your 401K around......weight distribution isn't an issue!!!!! Neither is cornering...... acceleration.....braking....., OK, you probably should have good braking......

Ciao! ![]()

Thanx for battery data.

Logistics question: Car is completely stripped of everything (including motor and mechanicals) so its pretty light. Have a 4500lb capacity winch attached to front cross bar of 4 post lift to pull goose onboard and will reassemble it on the lift. Not having towed the goose anywhere, what are the best attach structural points up front to wrap around a nylon tow rope forming a triangle shape to be reeled in with the winch? Thanx.

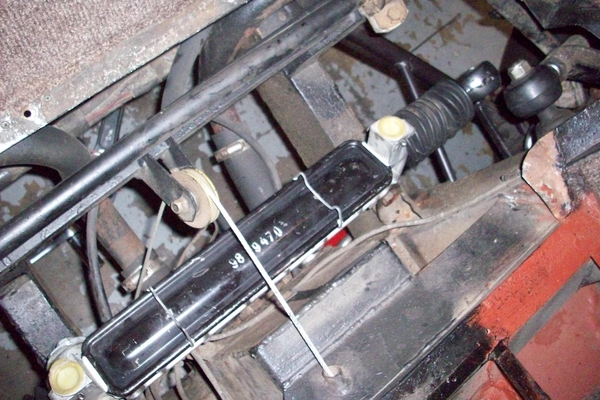

There may be a tow loop on the driver side of the frame rail, near front of car. The trouble is, unless winch is low to ground, using said loop would cause cable to come in contact with front facia, thus the need for a strap in a triangle shape at the front which makes a tow bar so to speak and saves the car from damage. Photo attached. I did not see exactly where the strap went.

Attachments

Hmmm, thought I responded to this post.......must have missed a key.....!!!

You can wrap straps around the lower frame rails up front. They are completely boxed and can handle this massive job. Depending on the lift and pull angles, you may want to put a 2x2 or 4x4 across the rails to keep the strap down off of the front valance.

In the pic, you can see the frame rails and the bracing...where you can sneak straps thru with no fear of slippage..... Please ignore my messy wiring........was trying to duplicate factory job..... ![]()

![]()

![]()

Attachments

Hi Mark, any updates on the project? PM sent! Regards, Nate

Well after 8 years, a couple different owners, a shop location change, and 3 Presidents, the paint job may be about finished. Looked at car today for pre-delivery inspection, still some things to clean up. Missing are Ghia emblems (no big deal), the forward latch on the drivers side for right rear lid (big deal), the black metal plate covering the vents of the right rear lid (can be made out of sheet metal), and both rear lid windows in front of the vents (big deal - will be have to be specialty made to fit).

Any ideas on the missing items?

The under side cover for the hatch "gills" was aluminium with a drain, but you have one to copy.

No use telling you that I used to have the hatch small windows......! Don't recall where they went.... Try Steve Wilkensen! Ya never know what he may have!

(Do you still have the chrome trim around the small hatch windows? These would be a bugger to do!)

Someone found the hatch latches in the past.....try searching this site! Maybe they'll chime in....

Ghia emblems in repop form are adhesive backed....stick 'em where needed!

Gotta feel good to see the car in color finally!!!!! Sharp color!!!

Cheers!

Steve

Here was as close as I could get to the latches...Lancia Appia, maybe Fulvia. Look on Ebay Italy. And Wilkinson just may have the port glass.

ALMOST GOT LOST on Lee's old post!!! ![]() )))

)))

Saw this below one of the links to a pointy thing auction! May be the same seller......

https://www.ebay.com/itm/255652132921

The above is one of the receptors of the pointy things...

See if cut n paste works....

Didn't seem like the GOose creators got this creative??? ![]()

Do you need the pointy thing for the hatch or the latch portion for the body?

Steve

Thanx for all the ideas. Will check out the various Lancia latches and see if I can find a suitable substitute. I did find a place in the UK that will reproduce the small rear lid windows in Lexan. Still will have to sort out seal and chrome trim.

Lee, in reading the threads, what did you end up using for a latch? Like you mentioned, this looks pretty close...

COMPLETE REAR TAILGATE LOCKING DEVICE (BAF33-0007409 - POS.15)

Complete tailgate locking device for Grecav Eke.

29.63 €

....just as I thought I could jail break out of Covid and go back home, my wife got pregnant and I'm still in Taiwan--I still haven't gotten a chance to see these pieces (that I ship to the car in Houston). But my money is betting on the Lancia Appia or Ardea pins/latch. Yeah, I bought the latch (not needing one, but still so curious if they are the same ![]() ) ...

) ...

To answer Steve's question, I have the male (upper) component of the forward left rear lid latching mechanism.

Lee, will hold off on buying Grecav Eke latch until I hear what you think of the Lancia pieces you have. Let us know what you think of those latches when you see them. By the way, where did you find/buy them?

Sorry for the delay--my suggestion is start with "scontro Perno" on Lancia Appia or Ardea, on Ebay Italy, and work backwards (contact the seller and see if they have a latch). The Grecav Eke may eventually work, but the pin is rounder. Here are a couple shots to take first;

https://www.ebay.it/itm/325746...p;LH_ItemCondition=4

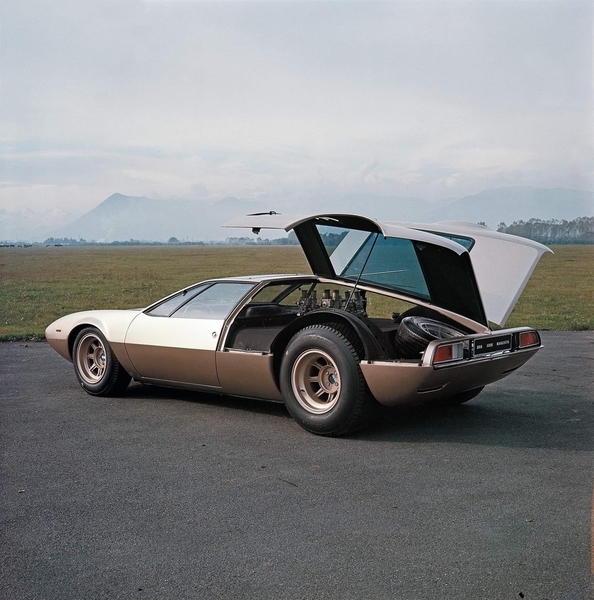

Saw all parts of Goose completely painted and polished in platinum yesterday. Looks pretty good. Shop is reassembling, cleaning/painting engine and side bays, and fabricating and installing some parts lost during the process.

Wheel wise, anyone know if the wheels on prototype were silver, or platinum, or a mix of the two colors? Right now my wheels are silver. Atch 1 is a pic 'Roger' posted a while back of the prototype that shows the wheels platinum. Atch 2 is the way my wheels were when I bought the car with the wheel centers/spokes matching the original color of the car.

Attachments

I wonder (loudly! ![]() ) if the gold insert wasn't an owner change....

) if the gold insert wasn't an owner change....

I have been seeking Ford Argent Wheel paint from VHT, for my new (to me) Pantera rims, and apparently the entire planet has been sucked dry of this version.

On my Goose I went with a BMW powder coating if I recall correctly. There are some Dupont numbers scrawled on the receipt, but it appears that it was a two part thing as one of them is clear....... I do not recall approving a two part.....as I hate two part paints.....trouble trouble trouble!!!

I think mine came out just a tad bright, but all I had to compare to was 15+ year old stripped to bare magnesium wheels.....not even close...!!!! So I just went with the BMW thing. Now, this was back in the early 00's that I had mine done. The coating held up VERY well!!!

Some pic's for you.

Steve

Attachments

MUTTSJET,

Wheels on #596 had gold paint on the spokes. I wish I knew the answers to your question about the finish on the prototype wheels. I'd like to spend the rest of the afternoon researching that but of course, life has other plans.

A cool trick is to finish with a clear coat but use what's called a 'knockdown' clear coat. Keeps things from looking too shiny. I think we used a 25% knockdown.

It gives a special glow to the wheels that's hard to describe. Pleasing to the eye but not distract from the rest of the car.

One more thing; a horror story from the gent who did my wheels-

Lamborghini Diablo has Campagnolo wheels. The shop refinished the wheels, reinstalled them, and torqued the lugs to the proper value. Customer picks up the Diablo and makes it down the street until the first high-speed turn. The front wheel came loose, flew off, and did massive damage to the car. Apparently, (according to the story) it was due to the fact that they refinished the area where the lug lands against the wheel. Either the slick finish or the added millimeters somehow caused the wheel to come loose. So moving forward the guy always leaves a tiny bare space where the lug lands. Not visible once the wheel is installed.

I always sort of suspected someone forgot to torque the wheels and that was the true cause. I mean of course, you're going to blame some exotic thing like refinishing because, with that construction, some of the blame is shirked off to the idea of an exotic and arcane cause. Makes you look a little less stupid than if you simply forgot to tighten the lugs. So potentially it's a BS story but I wanted to share for fun.

I looked at a bunch of cars listed on the PromaMO site. with the exception of a few cars with aftermarket wheels and the red car with gold inserts on the wheels, they all have what appears to be Argent Silver painted wheels identical in color to the Pantera wheel. I dont see anything that looks platinum. If you have an account, check them all out as there must be 250 cars on the site.

I think your picture may have been tinted or something as 001 is in the registry as posts by Mike Drew when seen in Italy and the wheels are just like all the other cars. Hope this helps.

Attachments

Simple answer. The 1st pic is the pusher the second is the driver when they converted the Prototipo to a real car. So both are correct. I have a wheel I acquired with little or no real road use. The color as Steve has mentioned are a Ford /Mazda silver. The wheels were clear coated and that clear has yellowed. Not as bad as the pic but still. I seem to remember a miura with gold wheels as well. That may have been a period thing to do.

What you want to do here is ditch the Boss 302 heads. Go with AFR #1388 heads.

They outflow stock Cleveland and B2 heads by a lot. Right around 300cfm out of the box with a mild .500" lift cam. Try 250's for C and B2 iron heads. They are Windsor style and will bolt up to your 'goose headers.

You will also loose 55 pounds from the engine assembly because they are aluminum and they are a direct replacement for 302 iron heads.

You can mill them up to .020" to play with the combustion chamber cc's. You can easily get them down to 54cc's.

Then you can go with a Cobra style Weber intake which are much more plentiful then B2 Weber intakes. How you deal with the jack shaft I don't know but I have seen Webers on running Mangusta's so it must be doable.

On using a jack shaft with IDA Webers it is possible. You won't be able the run the existing jackshaft, you have to fabricate 2 brackets at each end, its the jackshaft mount not the actual shaft that gets in the way. I can't seem to find a photo of the final set up we had, this are from the early mock up. We put the Webers on when contemplating racing it but found while its sounded awesome we never quite got to grips with (more like we didn't spent enough time to get to) a proper tune for it. Its was more powerful (or at least easier get the power) with the Holley. Torque and throttle response is much better with Webers though. There are a couple of IDA manifolds which are made and some have the carbs angled which I think could provide even more clearance for the jackshaft.

Hopefully the pictures assist.

IIRC we use chrome moly tube as you need to be conscious of Critical Speed and whip, if going full on to full off with the throttle. but again IIRC we only used bearings at each end not in the middle.

Cheers

Larry

Attachments

@leea posted:....just as I thought I could jail break out of Covid and go back home, my wife got pregnant and I'm still in Taiwan--I still haven't gotten a chance to see these pieces (that I ship to the car in Houston). But my money is betting on the Lancia Appia or Ardea pins/latch. Yeah, I bought the latch (not needing one, but still so curious if they are the same

) ...

Congratulations to you Sir! You might be surprised to read this; but babies can be born outside of Taiwan. No need to remain for that.

OK back on topic sorry for the hi-jack. ![]()

![]()

@scifi posted:Congratulations to you Sir! You might be surprised to read this; but babies can be born outside of Taiwan. No need to remain for that.

OK back on topic sorry for the hi-jack.

...well, the critical thing is that the wife got pregnant while I was in Taiwan... ![]() But I'll be sneaking back for the first time in almost 4 years, one month from now...

But I'll be sneaking back for the first time in almost 4 years, one month from now...

..btw, re: the whipping jackshaft---At least what strikes me is that the original jackshaft housing (as a single piece tied on both ends, and a very short distance between the mounting on the engine and the bearing centers) is different here (where front and rear uprights are independent, with apparently a long distance between mounting bolts and bearing center). Is there any feature necessary to align front to rear?

I can see why 8ma1074 mounted (with just a high rise manifold) their alternator to the front and (in Emeryville CA) sacrificed AC...)

Are the Ghia emblems on the front fenders 38mm tall? Trying to find a couple since they were lost in paint process.

Try sending Johnny woods a note he had a few OE Ghia NOS emblems stashed away a while back.

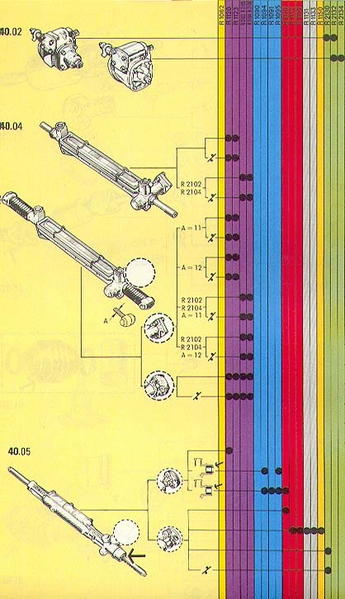

Steering question...does this steering rebuild kit for the Renault 4 rack look good [Steering rack repair full kit for Renault R4 4L from 1979 to end of production. - vehicules-anciens.fr]? What key points should be looked at when going over the disassembled rack to know what is good and bad? Also, should the heim joints and bushings on each end of the rack be replaced? If so, couldn't find the part number and where to order on the forum. Read forum discussion on the u-joint on steering column, but couldn't determine if there are replacement parts available, or if it is a unique part?

Wow, the gold paint looks great...really distinctive, so much remarkable than I had expected.

For the steering rack--who knows?! ![]() The housing itself seems to be a custom thing only for the Goose, but otherwise just suggest aiming a decade earlier on parts (say, for Dauphine)..Likely the stuff starting at 1979 and later mostly works, for some reason I think I bought parts from https://www.franzose.de/en/Renault/R4/steering-gear/ (just to have them, I haven't done the work).

The housing itself seems to be a custom thing only for the Goose, but otherwise just suggest aiming a decade earlier on parts (say, for Dauphine)..Likely the stuff starting at 1979 and later mostly works, for some reason I think I bought parts from https://www.franzose.de/en/Renault/R4/steering-gear/ (just to have them, I haven't done the work).

I had to change the inner tie rod ends/heim joints on mine. I just used the mfg number on them at the bearing shop. Got them in a few days at a reasonable price.

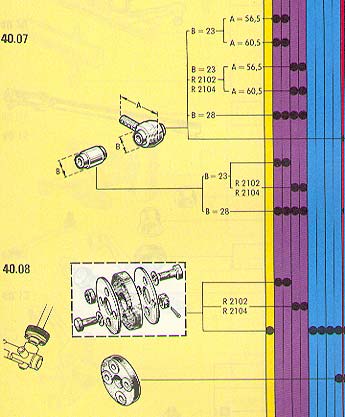

This is an area that I thought had been pretty much determined some time ago with the Dauphine being the winner (donor!). I recall taking my rack apart to see if there was any way to remove any slack in the rack.....and found very little to be able to do!

I think I just greased the Unibal joints, slapped on new rubber booties, packed the whole thing with some new grease and put the cover back on! A pretty hardy box if I may say so!

Here is where it get's dicey. Denis mentioned simply going to the bearing house with his parts in hand and coming home with new parts! While tie rod end may be true (Fiat part according to the parts book...... probably posted elsewhere on this site, but I don't have it handy(!) but in most cars, the Unibal joint was a very custom piece!

The rack center shaft may have been modified (shortened?) when compared to the stock Dauphine parts. I think it was modified to accept threaded Unibal (14? or 16) joints. That would be a MODIFIED Unibal joint where the threaded shaft section was turned down and rethreaded! (Likely why I greased mine and put new covers on....and called it! Actually the Unibals were in great shape and weren't loose and rattley like the a-arm ends!) (so glad for this!!)

You are not going to walk into a dealer anywhere and find these Unibal joints.

Denis, If you can post pics of your later version with bearings (where do they go? and how?) I think that would help some...... Cuz it sounds different....? Is yours a clamp in version (round clamps over body?)

Back to the original question, I think the "kit" would possibly work for the booties and the rag joint. The rest of the parts are a mystery.

Here are a couple of photos, but I must advise that they are not the best and I was lacking the foresight to take more pic's of the rack deshrouded!!!! Duh!

I added pic's of the frame mounts for this style of rack. It appears that there is a needle bearing on the steering shaft.... I don't recall what the shaft rode in, in the housing. Didn't seem like much at all....perhaps right on the aluminium?

There may have been some tensioning wipers under those towers that appear on either side of the cover. Again, my apologies for not using more bits in the camera to catch this stuff!!!! Someone, please fill in my blanks!

Attachments

Steve I think you are right the inner tie rods are Unibal heim joints and they were available quickly at a resonable price. What needed to be done was re-thread them as the component had been modified by Ghia. In my case the rack, booties and outer tie rods were all in fine shape. I remember Dick R posting the booties were still available aftermarket from European but they call them « gaiters »

Denis,

OK, good to understand! I didn't want guys to grab parts expecting that they were going to screw right in....... when these are anything but!

Ciao!

Steve

Denis and Nate, thanks this is what I remember also--that heims don't exist with the combination of Eye and Thread (so to replace, must start with a big heim and decrease the thread)

Rd rebuilding the steering rack, if you want to choose an alternative route and go to a close ratio rack, I had a company in UK that does motorsport steering design and manufacture a closer ratio rack to the same dimensions as original. I believe they export worldwide. If you or anyone is interested message me and I’ll set you up with the company as I “own” the design but am happy to make it available to any Mangusta owner. I think it’s 2.5:1 vs 4:1.

cheers

Larry

Larry,

I believe the racks on Panteras and ("most") Mangustas are like comparing apples and carrots. This discussion has been had in the past....

BUTT, I cannot speak for later versions of the GOose racks.......

Never had a problem driving our Goose with the factory rack.......plenty of problems everywhere else......! ![]()

![]()

![]()

IMHO, anyone needing a closer ratio rack is starting to think crazy thoughts about they expect to drive their cars.....which will cause problems in every other suspension component on and including the chassis! Tissue paper.....!

Keep in mind, the Goose is now a rolling 401K plan!!!! ![]()

Ciao!

Steve

So Steve, is the long and short of it for restoration of steering:

On each end...new outer tie rods, try to get lube into heim between inner tie rod and rack, new boots/gaiters filled with some lube on end of rack rod, and lube inside the main portion of rack.

I'm guessing at what I did back when I did it, but that's pretty close! After 30K+ miles as the car came to me...and with a few more.....I was amazed to find that my tie rod ends (outer) were still in really nice shape! Also amazed at the condition of the modified inner Heim joints, needing only grease and new rubber booties!!! I was not thrilled with the idea of having to find someone to cut the Heim threads to a smaller metric diameter/thread pattern. But didn't need to worry as there was no need.

As for the rest of the rack, there really wasn't much one could do! Lube the steering sector or input shaft..it only goes in one way(!)....so I believe I laid in mass quantities of grease-ish substance....don't recall using any oil of sorts......

I figured that if there was grease on the inside.....it can work itself outside....so I didn't see any need to fill the rubber bellows with something that was gonna end up all over my floor pan, oil pan, and rear suspension!!! ![]()

![]()

![]()

This is a very simple steering rack.......and I guess I was thankful for that!!! I concentrated on getting the rest of my a-arm heims and ball joints sorted out as they were in TOUGH shape!!! New ball joints were needed immediately as were a couple of the heims.....the nylon "T" bushings were in good shape. I replaced them with new....but turns out they weren't good for any positive change....could have left the old ones in place......! Not a fancy front suspension!

Attachments

Finally, after 8 yrs and 8 months, should have goose back next week!! Only items missing that shop is having made to give me after the fact are the chrome trims for the rear wing side windows. They lost windows and trim in the process. Since replacements were unobtanium, found replacements in plexi in uk. They look good.

Also, now have all four original rear latches! Paint shop found last one in pass compartment.

Hard work to begin now!

Attachments

Lost parts.......ugh!!!! How the shops miss-manage in order to do this....! So many stories across the industry......

Great progress otherwise!!! Very exciting to have it back in your shop soon!!!!!

The final assembly with my car was always fun....even though I never was doing a full resto.....but just with the engine rebuild, or the ZF, or the brakes as small projects...the last jackstand pulled out and the car lowered to have rubber meet the concrete was a good feeling!!!!

Jump in the car and turn the key.....go for a drive!!! NEVER a bad day when you can do that! ![]()

![]()

![]()

Cheers!

Steve

Just found this thread… what a great read!!

it’s amazing how projects slowly morph into a decade long endeavor…

Also the hunt for parts is exciting and frustrating at the same time… but, at least for my Pantera - Fiat-Group parts from 1968 seem to be most of the times a winner.. tiny Fiat 850 being a donor included..

beautiful car! Now the tedious work begins for you … 👍👍

Goose gets delivered Thursday! Have new front trunk and door rubber trim purchased years ago from Cicognani to install to protect paint. However, painters lost all trim around engine compartment. Can someone shoot me a pic of the rubber trim that attaches to the body on which the rear wings rest on? Thanx much.

Rubber seals in previous input taken care of....

Does the following flow of rebuild make sense? Any major muscle movements left out?

- Check all wire continuity

- Refresh front suspension and refresh steering

- Brake rebuild/overhaul with new brake lines

- Clutch lines rebuild

- Rebuild doors

- Refresh interior

- Run rebuilt motor with all cooling and ignition from car on test stand

- Refresh all hoses

- Move motor, cooling, ignition from test stand to car

- Lights/horn/electrics, grate, trim on front end

- Lights/electrics/remote starter/battery on rear end

- Install exhaust system (possibly rebuild new exhaust like Dick Ruzzin's over the top bundle of snakes due to width of Boss 302 heads)

Congrats, car & color look fantastic!! Please keep us posted as the re-assembly moves forward!

Hopefully somebody has a solution for that elusive seal - - I've never gotten any handle on what the original version (if any...) looked like. My car came with a strip of urethane foam, ~3/4" wide, adhered to the body surface, in that small 'valley' just ahead of the pinch weld. Height varied across the length of this strip, depending on the size of the gap to fill. (IIRC it was thinnest across the roof area, and significantly thicker along the two sides). Maybe it served a purpose but it didn't look like an OEM feature.

All I know is that originally there was a faux-chrome plastic edge-bead along the pinch weld flange, where you have the seal installed. The available clearance over the flange is minimal (especially at the top corners of the cabin area), so nothing thicker than edge-bead fits.

So for an original look, faux-chrome beading is a 'yes', gasket/seal is a '?!? '