Getting real close!

Steering question...does this steering rebuild kit for the Renault 4 rack look good [Steering rack repair full kit for Renault R4 4L from 1979 to end of production. - vehicules-anciens.fr]? What key points should be looked at when going over the disassembled rack to know what is good and bad? Also, should the heim joints and bushings on each end of the rack be replaced? If so, couldn't find the part number and where to order on the forum. Read forum discussion on the u-joint on steering column, but couldn't determine if there are replacement parts available, or if it is a unique part?

Wow, the gold paint looks great...really distinctive, so much remarkable than I had expected.

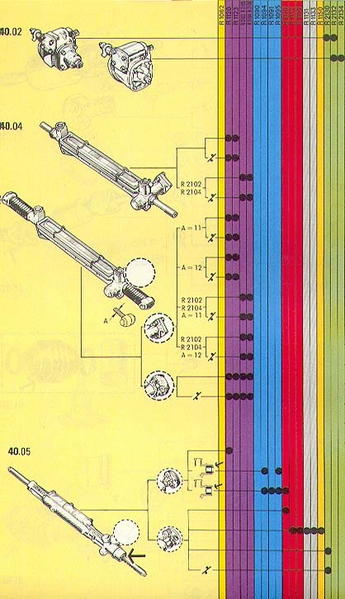

For the steering rack--who knows?! ![]() The housing itself seems to be a custom thing only for the Goose, but otherwise just suggest aiming a decade earlier on parts (say, for Dauphine)..Likely the stuff starting at 1979 and later mostly works, for some reason I think I bought parts from https://www.franzose.de/en/Renault/R4/steering-gear/ (just to have them, I haven't done the work).

The housing itself seems to be a custom thing only for the Goose, but otherwise just suggest aiming a decade earlier on parts (say, for Dauphine)..Likely the stuff starting at 1979 and later mostly works, for some reason I think I bought parts from https://www.franzose.de/en/Renault/R4/steering-gear/ (just to have them, I haven't done the work).

I had to change the inner tie rod ends/heim joints on mine. I just used the mfg number on them at the bearing shop. Got them in a few days at a reasonable price.

This is an area that I thought had been pretty much determined some time ago with the Dauphine being the winner (donor!). I recall taking my rack apart to see if there was any way to remove any slack in the rack.....and found very little to be able to do!

I think I just greased the Unibal joints, slapped on new rubber booties, packed the whole thing with some new grease and put the cover back on! A pretty hardy box if I may say so!

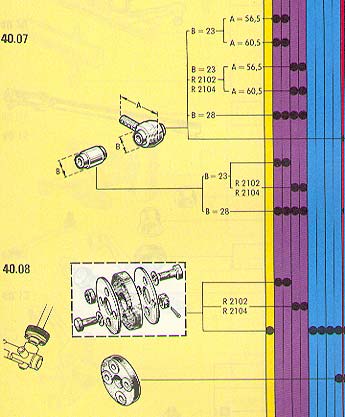

Here is where it get's dicey. Denis mentioned simply going to the bearing house with his parts in hand and coming home with new parts! While tie rod end may be true (Fiat part according to the parts book...... probably posted elsewhere on this site, but I don't have it handy(!) but in most cars, the Unibal joint was a very custom piece!

The rack center shaft may have been modified (shortened?) when compared to the stock Dauphine parts. I think it was modified to accept threaded Unibal (14? or 16) joints. That would be a MODIFIED Unibal joint where the threaded shaft section was turned down and rethreaded! (Likely why I greased mine and put new covers on....and called it! Actually the Unibals were in great shape and weren't loose and rattley like the a-arm ends!) (so glad for this!!)

You are not going to walk into a dealer anywhere and find these Unibal joints.

Denis, If you can post pics of your later version with bearings (where do they go? and how?) I think that would help some...... Cuz it sounds different....? Is yours a clamp in version (round clamps over body?)

Back to the original question, I think the "kit" would possibly work for the booties and the rag joint. The rest of the parts are a mystery.

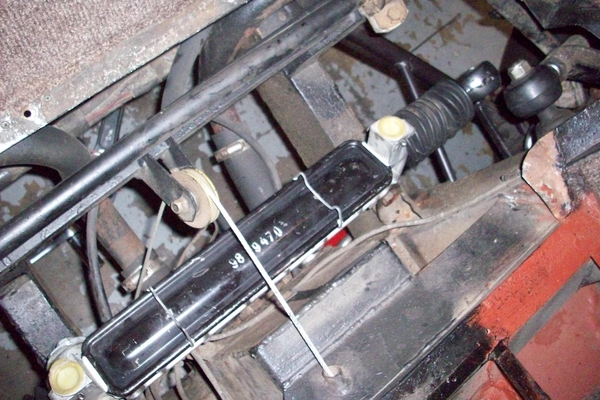

Here are a couple of photos, but I must advise that they are not the best and I was lacking the foresight to take more pic's of the rack deshrouded!!!! Duh!

I added pic's of the frame mounts for this style of rack. It appears that there is a needle bearing on the steering shaft.... I don't recall what the shaft rode in, in the housing. Didn't seem like much at all....perhaps right on the aluminium?

There may have been some tensioning wipers under those towers that appear on either side of the cover. Again, my apologies for not using more bits in the camera to catch this stuff!!!! Someone, please fill in my blanks!

Attachments

Steve I think you are right the inner tie rods are Unibal heim joints and they were available quickly at a resonable price. What needed to be done was re-thread them as the component had been modified by Ghia. In my case the rack, booties and outer tie rods were all in fine shape. I remember Dick R posting the booties were still available aftermarket from European but they call them « gaiters »

Denis,

OK, good to understand! I didn't want guys to grab parts expecting that they were going to screw right in....... when these are anything but!

Ciao!

Steve

Denis and Nate, thanks this is what I remember also--that heims don't exist with the combination of Eye and Thread (so to replace, must start with a big heim and decrease the thread)

Rd rebuilding the steering rack, if you want to choose an alternative route and go to a close ratio rack, I had a company in UK that does motorsport steering design and manufacture a closer ratio rack to the same dimensions as original. I believe they export worldwide. If you or anyone is interested message me and I’ll set you up with the company as I “own” the design but am happy to make it available to any Mangusta owner. I think it’s 2.5:1 vs 4:1.

cheers

Larry

Larry,

I believe the racks on Panteras and ("most") Mangustas are like comparing apples and carrots. This discussion has been had in the past....

BUTT, I cannot speak for later versions of the GOose racks.......

Never had a problem driving our Goose with the factory rack.......plenty of problems everywhere else......! ![]()

![]()

![]()

IMHO, anyone needing a closer ratio rack is starting to think crazy thoughts about they expect to drive their cars.....which will cause problems in every other suspension component on and including the chassis! Tissue paper.....!

Keep in mind, the Goose is now a rolling 401K plan!!!! ![]()

Ciao!

Steve

So Steve, is the long and short of it for restoration of steering:

On each end...new outer tie rods, try to get lube into heim between inner tie rod and rack, new boots/gaiters filled with some lube on end of rack rod, and lube inside the main portion of rack.

I'm guessing at what I did back when I did it, but that's pretty close! After 30K+ miles as the car came to me...and with a few more.....I was amazed to find that my tie rod ends (outer) were still in really nice shape! Also amazed at the condition of the modified inner Heim joints, needing only grease and new rubber booties!!! I was not thrilled with the idea of having to find someone to cut the Heim threads to a smaller metric diameter/thread pattern. But didn't need to worry as there was no need.

As for the rest of the rack, there really wasn't much one could do! Lube the steering sector or input shaft..it only goes in one way(!)....so I believe I laid in mass quantities of grease-ish substance....don't recall using any oil of sorts......

I figured that if there was grease on the inside.....it can work itself outside....so I didn't see any need to fill the rubber bellows with something that was gonna end up all over my floor pan, oil pan, and rear suspension!!! ![]()

![]()

![]()

This is a very simple steering rack.......and I guess I was thankful for that!!! I concentrated on getting the rest of my a-arm heims and ball joints sorted out as they were in TOUGH shape!!! New ball joints were needed immediately as were a couple of the heims.....the nylon "T" bushings were in good shape. I replaced them with new....but turns out they weren't good for any positive change....could have left the old ones in place......! Not a fancy front suspension!

Attachments

Finally, after 8 yrs and 8 months, should have goose back next week!! Only items missing that shop is having made to give me after the fact are the chrome trims for the rear wing side windows. They lost windows and trim in the process. Since replacements were unobtanium, found replacements in plexi in uk. They look good.

Also, now have all four original rear latches! Paint shop found last one in pass compartment.

Hard work to begin now!

Attachments

Lost parts.......ugh!!!! How the shops miss-manage in order to do this....! So many stories across the industry......

Great progress otherwise!!! Very exciting to have it back in your shop soon!!!!!

The final assembly with my car was always fun....even though I never was doing a full resto.....but just with the engine rebuild, or the ZF, or the brakes as small projects...the last jackstand pulled out and the car lowered to have rubber meet the concrete was a good feeling!!!!

Jump in the car and turn the key.....go for a drive!!! NEVER a bad day when you can do that! ![]()

![]()

![]()

Cheers!

Steve

Just found this thread… what a great read!!

it’s amazing how projects slowly morph into a decade long endeavor…

Also the hunt for parts is exciting and frustrating at the same time… but, at least for my Pantera - Fiat-Group parts from 1968 seem to be most of the times a winner.. tiny Fiat 850 being a donor included..

beautiful car! Now the tedious work begins for you … 👍👍

Goose gets delivered Thursday! Have new front trunk and door rubber trim purchased years ago from Cicognani to install to protect paint. However, painters lost all trim around engine compartment. Can someone shoot me a pic of the rubber trim that attaches to the body on which the rear wings rest on? Thanx much.

Rubber seals in previous input taken care of....

Does the following flow of rebuild make sense? Any major muscle movements left out?

- Check all wire continuity

- Refresh front suspension and refresh steering

- Brake rebuild/overhaul with new brake lines

- Clutch lines rebuild

- Rebuild doors

- Refresh interior

- Run rebuilt motor with all cooling and ignition from car on test stand

- Refresh all hoses

- Move motor, cooling, ignition from test stand to car

- Lights/horn/electrics, grate, trim on front end

- Lights/electrics/remote starter/battery on rear end

- Install exhaust system (possibly rebuild new exhaust like Dick Ruzzin's over the top bundle of snakes due to width of Boss 302 heads)

Congrats, car & color look fantastic!! Please keep us posted as the re-assembly moves forward!

Hopefully somebody has a solution for that elusive seal - - I've never gotten any handle on what the original version (if any...) looked like. My car came with a strip of urethane foam, ~3/4" wide, adhered to the body surface, in that small 'valley' just ahead of the pinch weld. Height varied across the length of this strip, depending on the size of the gap to fill. (IIRC it was thinnest across the roof area, and significantly thicker along the two sides). Maybe it served a purpose but it didn't look like an OEM feature.

All I know is that originally there was a faux-chrome plastic edge-bead along the pinch weld flange, where you have the seal installed. The available clearance over the flange is minimal (especially at the top corners of the cabin area), so nothing thicker than edge-bead fits.

So for an original look, faux-chrome beading is a 'yes', gasket/seal is a '?!? '