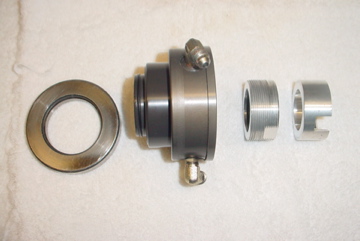

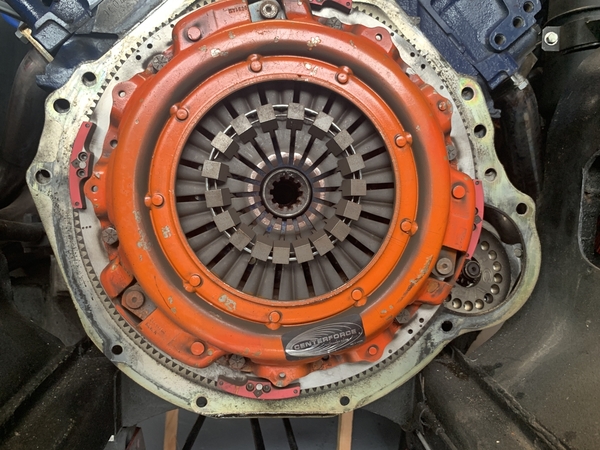

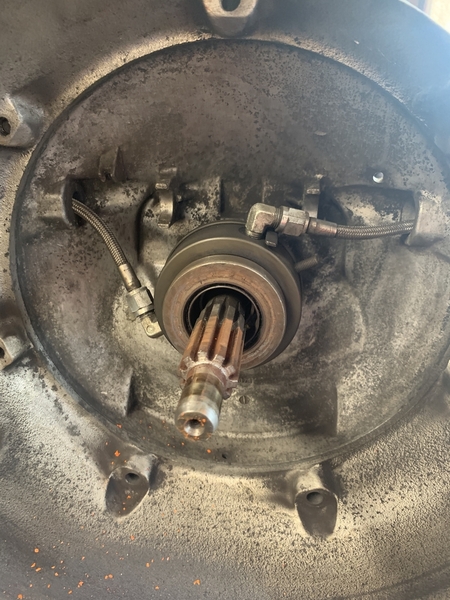

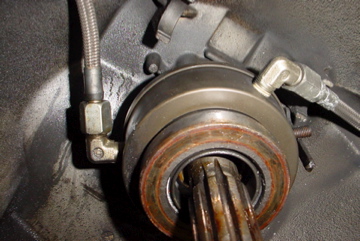

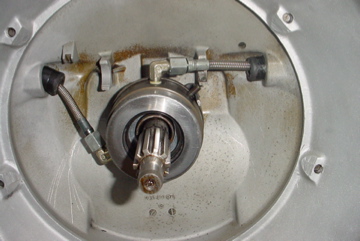

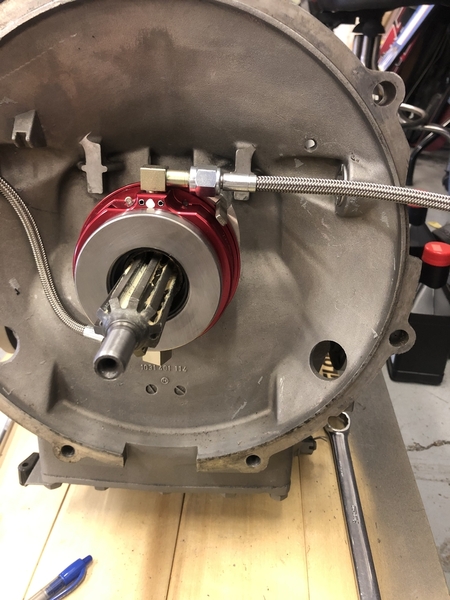

I have a car with an aftermarket internal clutch slave cylinder, pressure plate, and disc. The slave is relocated on the inside of the bell housing and it surrounds the input shaft (no photo of this). You can see the braided line that goes into the bell housing where the factory clutch actuating shaft would reside.

The clutch is slipping, particularly on the freeway when accelerating. Initially I concluded that the clutch needs to be redone. But after getting a better understanding of the factory slave and clutch configuration, I am wondering if the clutch in question above is only out of adjustment. Yet it seems that there is no adjustment for this setup without pulling the transaxle. What is your experience with this setup?