Nate, I'd never thought about even the risk...! In my one time up on this, I think I used the intake manifold in the first step only to support the engine lifting plate---and the only thing I'm sure of is that I installed sealant (and torqued, if not even re-torqued) with the engine in place in the engine bay. And then re-stabbed the distributor, and then the replacement oil pan...Lee

@nate posted:Back to the jackshaft assembly for a moment...I've always tried to install the jackshaft and intake manifold at the same time, torqueing all bolts in the proper sequence, and avoided removing the jackshaft alone later for fear of promoting manifold leaks.

Thinking now this is excessive caution.....but it begs a question: If the jackshaft is removed by removing it's four main bolts/screws, should the 8 other manifold bolts be loosened and ultimately re-tightened in proper sequence, or should they just be left alone, to minimize possible disturbance to manifold sealing surfaces?

I can see an argument for either option, anybody end up with a leak after R&R of a jackshaft? Thanks! Nate

I'm VERY likely wrong on this, but since there is relatively little force exerted on the intake manifold compared to main bearings, cylinder heads, and such, I wasn't particularly worried about disturbing the seals. Of course the fact that I hadn't even considered that MIGHT have been a contributing factor.

Hopefully this rebuild will be the last one for a while and will be torqued to spec with the jackshaft in place.

MH

Into the rabbit hole we go!

After MUCH deliberation I have decided to go back almost completely stock with the engine, I will send the engine off for a complete refresh/rebuild. I'm considering some minor improvements to valves and cam, but haven't made those decisions yet. I also have a set of "never installed" Hall Pantera big bore headers that I'm considering... If I can mount the heat shields to hide them, I may go that route. The main goal is to keep as close to original (at least externally) as possible.

I drilled discreet alignment holes on the spine mounts AND the wing mounts on the left side, removed the left wing, then the spine with the right wing still attached. A far simpler task than I had feared!!! a minimum 2 man job ( I had three just in case), but not difficult at all. In a car known for pushing the envelope of the term "difficult", this was a pleasant surprise...

These pictures were early in the day. I've since removed the spare tire support beam, alternator, A/C compressor, carb, distributor, plugs and detached the exhaust manifolds.

Next session will see the seats and console come out to access the portal and remove the jackshaft and coolant hoses.

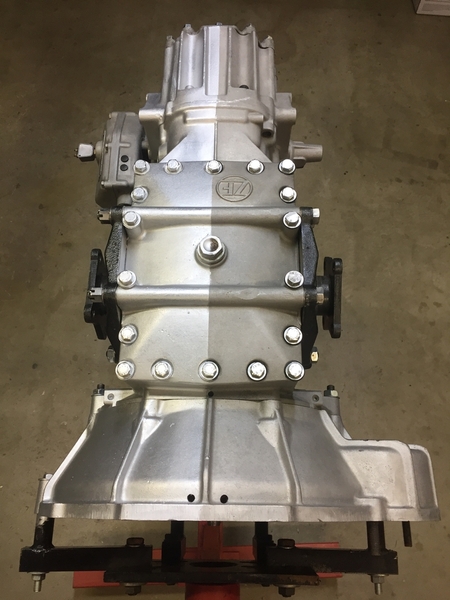

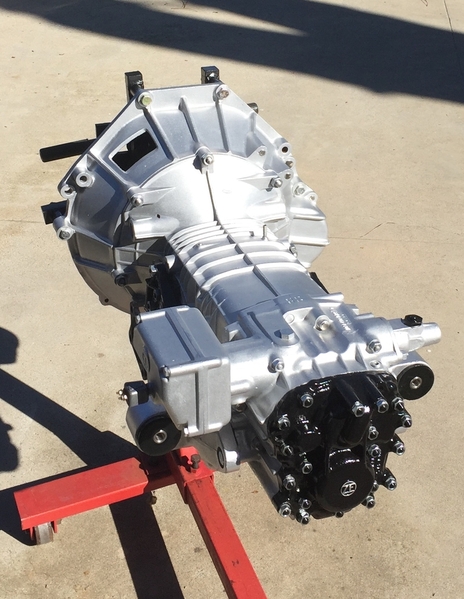

I'm still undecided on whether to remove the ZF first or to pull the engine and ZF together.

What is the proper procedure for removing the frame bridge and the other Assembly/Bars/Doohicky that the upper shock mounts are on (I'll just call it the "ABD" for now}? I think that I need to put the car on jackstands and take the weight off the shocks but I'm waist deep in new waters here. Do I need to put another jack under the ZF?

On a side note, I scored a set of Dodge Rampage mirrors for $95

That gets everyone up to speed. suggestions, warnings, advice and even criticism are all welcome at this point.

MH

Attachments

M!ke, I installed with ZF attached, using a balance tied to the ZF in the back and a carb plate--angled with the ZF up to nose under the 'shelf' on the rear bulkhead. I don't remember it clearly (so good news, must have been uneventful ![]() ) but I think removal is (after the engine mounts are unbolted) to loosen the alternator bridge (relieve pressure on the springs, pull the shock bolt and move the bridge out of the way, then re-stab the shock with the bridge in place. Support the ZF and remove the ZF support, then chain the engine balance to the ZF and carb plate. I think no secret at all, really, you've already done the hard work! Lee

) but I think removal is (after the engine mounts are unbolted) to loosen the alternator bridge (relieve pressure on the springs, pull the shock bolt and move the bridge out of the way, then re-stab the shock with the bridge in place. Support the ZF and remove the ZF support, then chain the engine balance to the ZF and carb plate. I think no secret at all, really, you've already done the hard work! Lee

Attachments

Looks like the jackshaft should come off before the pull, is that correct?

she's almost ready to come out... just a few hoses to go...

MH

Yes, my suggestion is remove the whole jackshaft assy off the manifold, or at least the front pulley (since the pulley nestles under the rear bulkhead metal...or at least, is one less thing to pop thru the window)--Lee

@lf-tp2511 posted:“I will have the ZF vapor blasted….”

I assume you mean blasting with dry ice pellets?

I was able to find a local business that did that for my ZF during the reassembly of 2511. It gave a very clean surface but it didn’t return everything to the same uniform appearance. It seems cast aluminum pieces, after 50 years of use, are hard to return to original.

I chose to do something others have used before me, a colored Carnuba wax called rub n buff. As others advised me, it seems to be holding up quite well and allows the bell housing and the ZF case to have matching appearance

left side is with the wax, right side is the dry ice blasted finish. there is a darker gray wax available that would be a closer match to the cleaned surface, but I opted for a little bit more shine

it comes in a 1/2 ounce tube and the coverage is phenomenal. I used one tube and maybe 1/4 of a second tube for the entire projectLarry

Looks great.

Vapor blasting is a combination of water and glass beads. It leaves a low gloss gleam kind of like a new Edelbrock intake manifold has.

It's kind of new to the "US" as "restorers" and is more of an industrial finish. So if you find someone locally that does it, likely they are industrial and caution should prevail on the consideration of the handling of your ZF. Like they would give two shits if they wrecked it for you?

I only know of one guy "in the hobby" doing it. It's part time for him and he does it in the back of his garage. Not here. In Texas and you need to get the parts to him and I'm not sure how good he is at shipping the stuff back to you?

It definitely will give you the "new gleam" that you want on the case.

I think a regular old Pantera has a much cooler look and styling ( not very Supercarish ) than a Goose and I never really closely looked at one but, I will say the jack shaft that operates the A/C compressor is awesome, what a neat design.

What has been called vapor blasting is more commonly referred to here in the US as dustless blasting. It can use different medias but they are always mixed with water, thus the name dustless blasting. I don’t know what the gentleman in Texas might be doing that is unique, but vapor/dustless blasting is offered just about everywhere these days.

I think the term “vapor” is a misnomer. it does not miraculously vaporize but instead leaves a muddy sludge which I suppose has some advantages over a dust storm. 🤷♂️

I would never consider any media blasting on an assembled ZF. Strictly an approach to do on an empty case.

The beauty of Dry Ice Blasting is there is no media to get blown inside and grind up the gears. The “media” is the dry ice and yes it does turn to a vapor, with the only residue being left behind is the material that was removed from the surface. For this reason it is often used in food processing facilities on processing lines

do a YouTube search for Dry Ice Blasting and you will find there are specialists in the automotive hobby world working wonders with this approach

Larry

Have you ever seen a Magnusen supercharger on a C6 w/LT2 or an SSR. The blower is driven from the rear with a jack shaft.

Jack shafts, what a concept. Larry, a friend of mine has two truck mounted blaster as you describe. He keeps these going by doing prep jobs at Legoland, Sea world, Disneyland and government places that require minimal impact to the environment. I have used this system to do complete cars but, all the materials get expensive even though I get to use the machine for free. It is still a lot of work so, I just hall everything to my blaster guy and be done with it.

Donny,

are we talking about the same thing, Dry Ice Blasting? The only materials needed are the Dry Ice and the machine.

I have never priced blocks of dry ice, or tanks of CO2 if the machine is high end and makes its own pellets, but I don’t think it is terribly expensive?

Larry

M!ke, a neighbor of mine in New Ulm had 5 BMW motorcycles, none newer than 1964 and each beautiful. His answer to restoring aluminum--WD40. That simple, same logic as lanolin for leather---it floods out the dirt and provides a consistent finish, voila. Not that I'm sorry that I once polished out the valve covers on the 308 (like I'm not sorry for polishing the water tank in the Goose!), but though its sad, its true, the cool thing in the Mangusta engine bay is not the drive train--you can barely find it under everything--its really just the open tube frame...

Denis, that is one mean application for jackshaft (!) An an interesting exercise in packaging for DeT to have enabled the engine to be just a few inches towards center. One of my favorite Binky episodes is the most recent one--even after 36 episodes of making brackets... The issue they had with their flex shaft (where the inertia of the accessories was tearing it apart and so they built the clutch function on it) was pretty amazing. Thanks for the tip on that channel so long ago--Lee

When your doing large projects like a car getting it inside and out it can can cost a lot and take much time but, if your doing separate smaller parts, no biggie. Several years ago I bought a Barrel blaster for doing smaller to medium size parts that works awesome, It's made in the great state of Texas.

Is it safe to assume the shifter linkage yoke will slide out of the ZF when I lift the engine or should I remove it (and if so, how)?. From the looks of it, the oil filter must be removed too... Does that mean the engine has to be reinstalled sans-filter? Last oil filter change took me 20 min to get the filter out. PO swapped oil pan For a custom pan which didn't make it any easier.

I should have the engine out this weekend

While the engine is at the machine shop I'll begin the engine bay restoration... as well as suspension...

MH

Attachments

What ever you do do not unscrew the yoke. Pull the pin forward of the joint. That way there will be no need to re-adjust the shifter when you re-assemble the car.

Mike, you will need to separate the ZF; I just remember this was damn hard, everything was stuck....But the shifter fork is secured inside the shifter box by 2 "grub" screws--using maybe ~4-5mm allen wrench screws that access thru the small rubber grommets on the top of the shifter box. The pin that held the rear of the yoke is still stuck for my car, I think others have noted that the hardened pin just gets harder if you try drilling on it...Since the adjustment on the front was also stuck (had to take it to a machinist who put huge amounts of heat on it, its bathed really well in anti-sieze now and I think I located a new giant fine-pitch nut.). But I may have taken the U-joint apart to get the engine out of the car.

I actually thought adjusting the shifter was not difficult on re-assembly. If you can't punch out the pin, and are going to try and drill, get some amazing drill bit and make sure its cutting...Lee

Attachments

Glad I asked !!! I was hoping it was similar to the yoke on a driveshaft that just slides into a transmission... Denisc, i'll have a look later today to see if I can find the pin you referred to.

Thanks guys...

MH

Mike, here is another view; the pin that Denis mentions is definitely the best to access, its worth spending a long suffering time to try and pull it out. Otherwise, the access to the 2 grubs screws is shown here, once removed then yes the shaft can slide forward out of the arm that responds to left/right gear selection...

There should be a boot right outside the shifter box on the shaft, mine evaporated but you must have either grub screws or the "pin" removed to replace. I think I simply unscrewed at the adjustment coupling on the far side of the U-joint to detach from the shift linkage. I've since found replacement u-joints (3 of them somewhere on the shelf, feel free to look, just leave me one for the day I get a chance ![]() .

.

The then 40-something year old seal finally started seeping after all put together...the shift box should be dry, but suggest getting a replacement seal (it and the grub screws are cheap at Wilkinson, same as the shift boot).

Attachments

Alas, I didn't see that pin... I ended up marking the set-nuts on the turnbuckle adjuster bolt and then unthreading it...

Then I log in to read Denis's "Whatever you do" warning NOT to do what I had JUST done... (a recurring theme in my life).

So, last night a friend from the Ferrari world (who is helping me on this project) and I went to go see that 'other' goose in town.

Lee, you might recognize this one

I wanted to get a look at a proper engine bay... While 898 seems to be very original, Various parts have been replaced over the past 53 years and not always with the correct parts.

@johnnywoods I've been pouring over the gorgeous engine bay restoration you were kind enough to document online. I wanted to ask about the zinc/passivate plating that you had done, was that personal choice, customer request or "factory correct"? I love the look, but haven't seen much of that in other Mangusta pics... Of course rattle can black spray paint IS a cheaper solution many others (including msyelf) have turned to from time to time.

MH