Michael,

Some pictures in here for you:

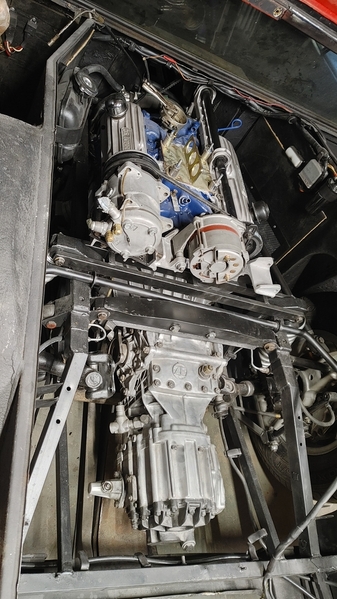

https://pantera.infopop.cc/top...a-clutch-help-please

Pilot bearing: INA #HK1512

I used a double lipped rubber seal that I found instead of a leather version which should be original...... 15x21x5 MOS/D Double Lip Oil Seal. Sourced via Rocket Seals in Denver. YMMV!

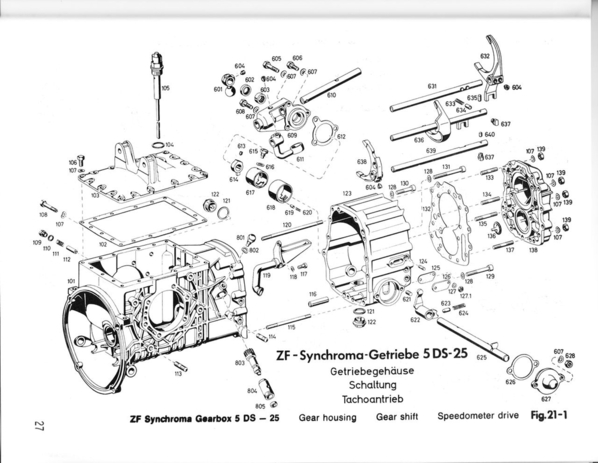

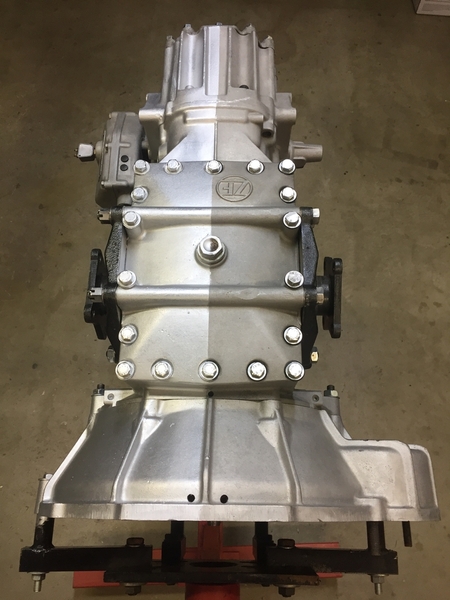

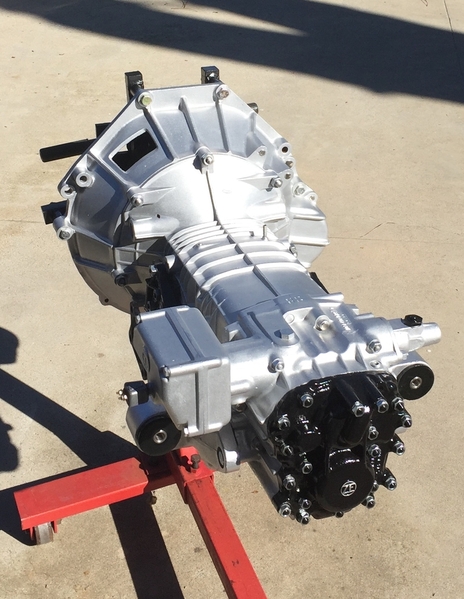

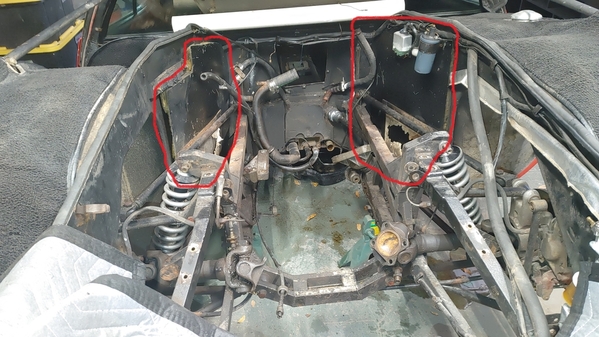

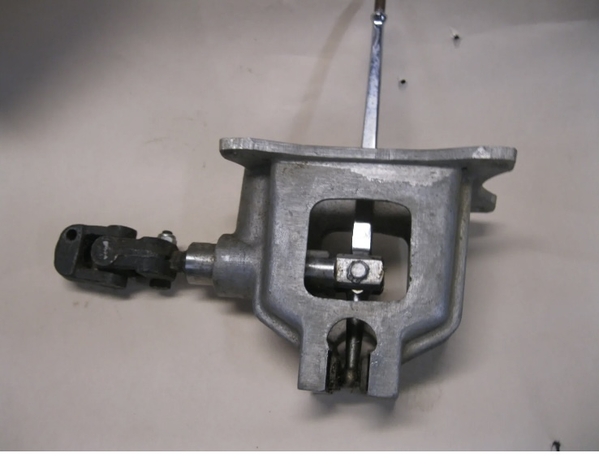

As for more info: Try my post: OOPS I'm Doing It Again..... for my rebuild process of last engine and ZF adventure....plus cracks...... I thought I posted all of the clutch info there also.

Pressure plate is stock 1968 Ford Mustang 302 clutch. I ran a 10.5" "synthetic" material (Kevlar like..) on both sides of the disc. Disc is supposed to be some sort of Mopar piece that my clutch guy found before he passed away......bummer! Besides losing a friend of the marque, lost all of the info too! See top post for pic's of it!

Throw out bearing is stock Mustang Bower/BCA 1625 I believe. (same as Pantera.)

Note that the clutch disc and pressure plate all say 10" but you can run a 10,5" disc with this pressure plate, no problem.

Pressure plate was C7ZZ-? number......if I must I could be persuaded to dig thru my receipts for the actual number. Goose parts book lists a undeciperable partial Ford number.... might be C7TA.....

I "may" have installed a HiPo 289/Boss 302 pressure plate.... C7ZZ-7550-A... My apologies for dead brain cells!!!!!

My Master Ford Parts Catalog lists the following pressure plate for a 1968 302 with 10" clutch: C6OZ-7550-G Likely this is what came in the cars.

I know that my original flywheel had the proper C7TA(?) stamping on the backside which accepted the 10.5" components just fine, no redrilling required!

I found this from email dated 2010, but could be earlier:

My friend found me a clutch that fits the ‘goose with no modifications. Its McLeod part number 260140. I’m also using it with Hays pressure plate part number Hay-52-105 which was given to me by Roland Jaeckal. Haven’t road tested it yet but it specs out the same and the hub shaft clears the crank adapter with no machining. I’ll attach it tomorrow and hopefully get the engine installed sometime this week

Sorry for the goofy format!!! Tried to fix it but failed.....short of typing it all over again.....

We REALLY NEED TO GET STICKIES for this website activated.....so that we can start a data reference area for this post and the other 401 just like it!!!  Post it once......more......! Read many.......! George???

Post it once......more......! Read many.......! George???

Cheers!

Steve