Just getting caught up on some of the updates... First...I think 45min drivetrain removal may be a record.

- Sorry to hear about the rod bearing. I share your concern...why did it happen. I never like just moving forward w/o fully understanding the failure. Seems every time it do, I ended up with the failure again...

- Would love to see some detailed pics of the trans fixture when you get a chance.

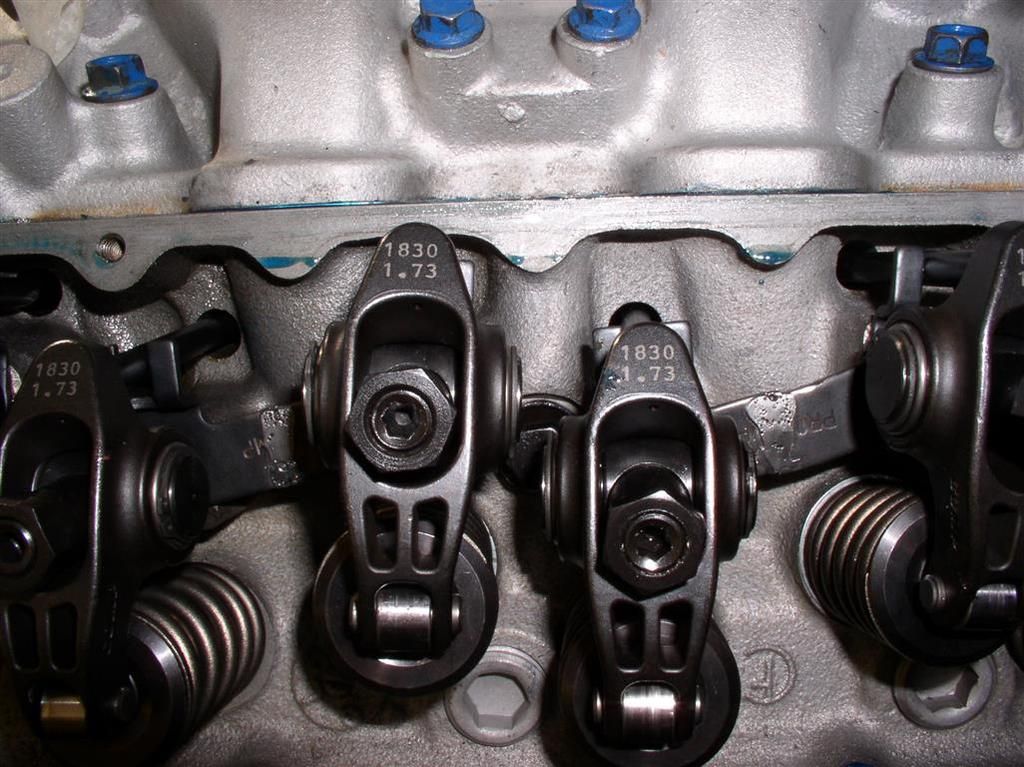

- On the heads, what did you mean by "minor hole drilling for water flow"? I have never done this on the 351C heads, and would like to understand it more.

Keep us posted.