My skills are not as tremendous, but I have the help and assistance of a an expert Pantera enthusiast and Hot Rodder (Wade - 4280 / Mark IV) and the resources of this board.

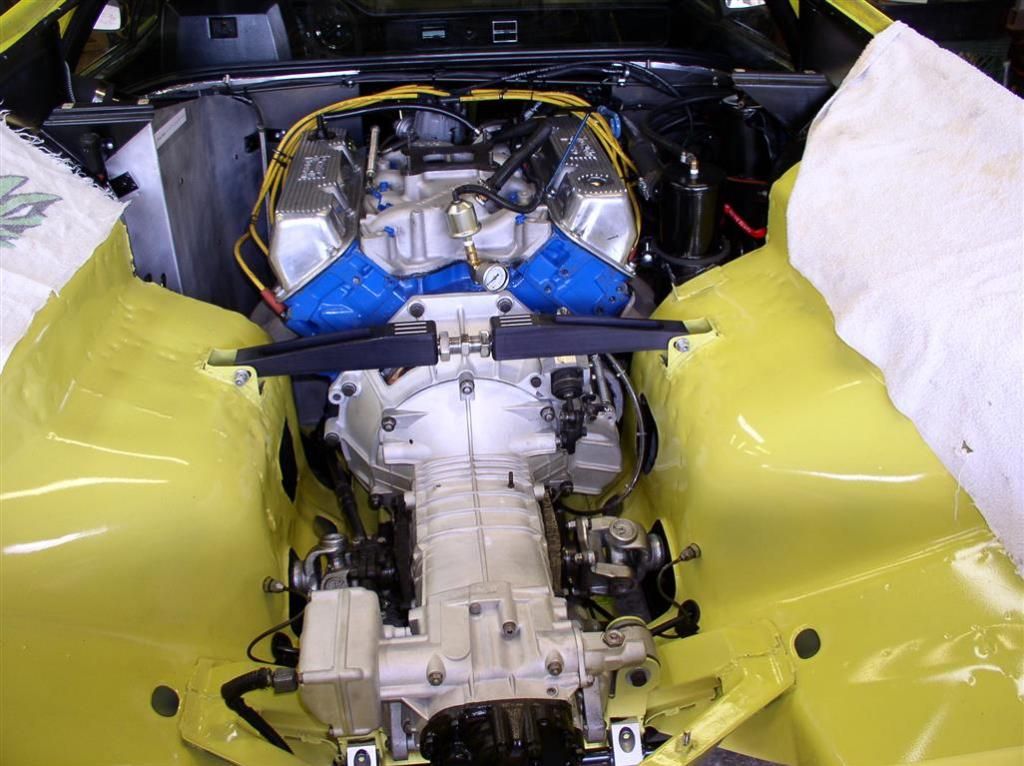

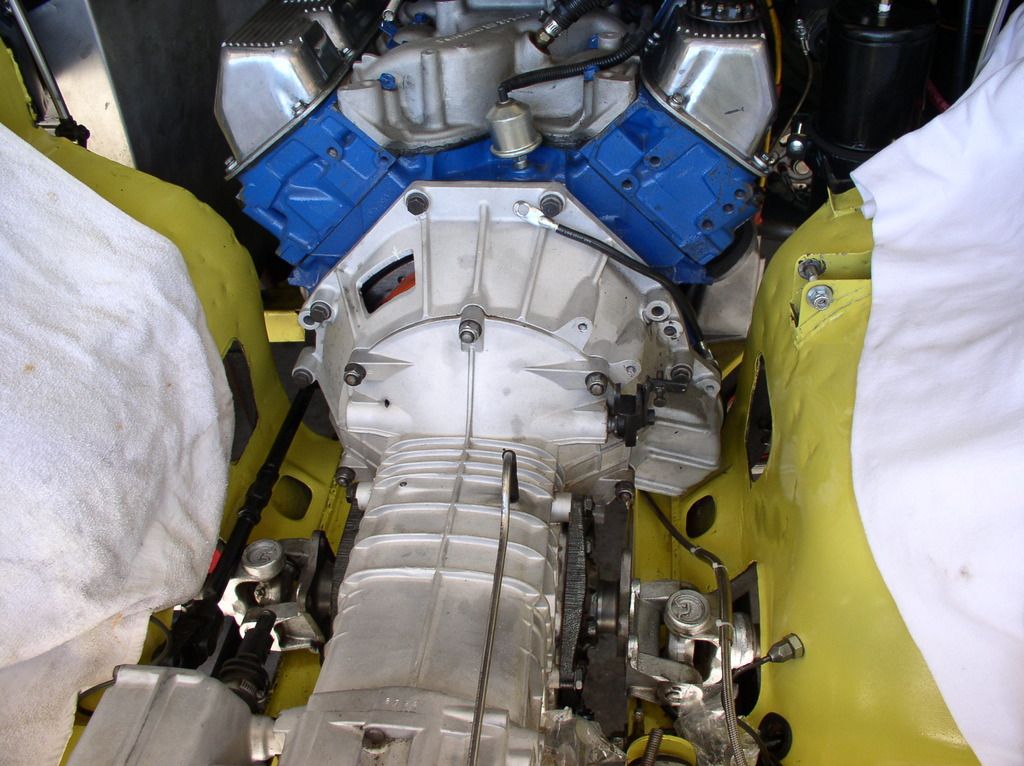

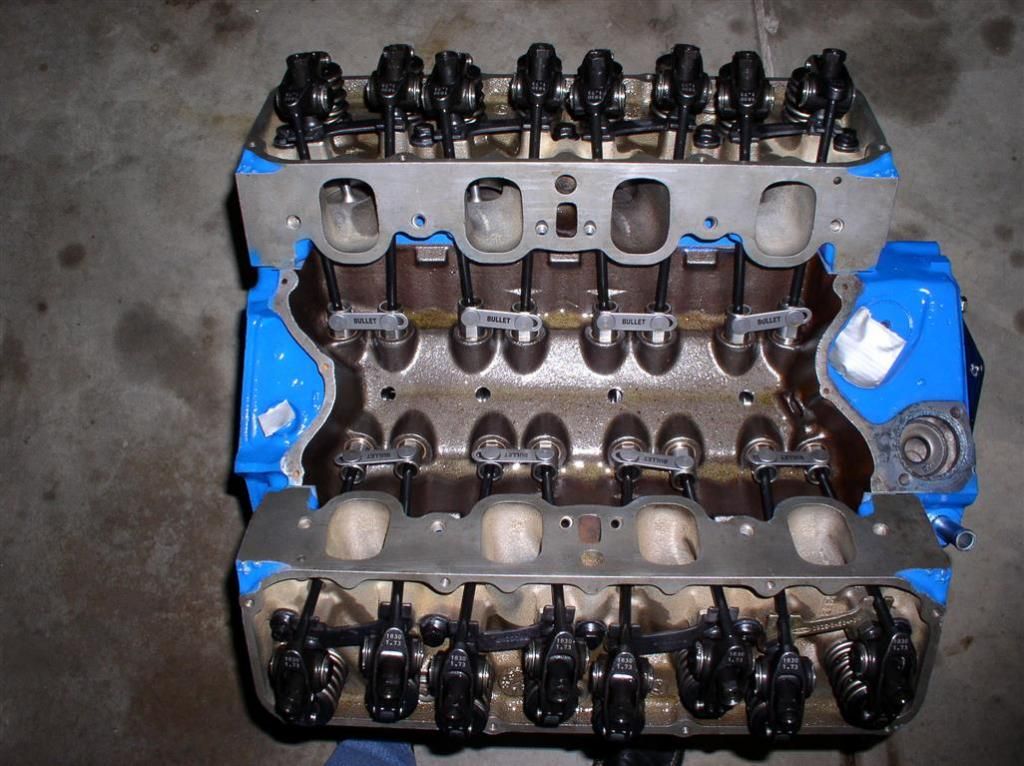

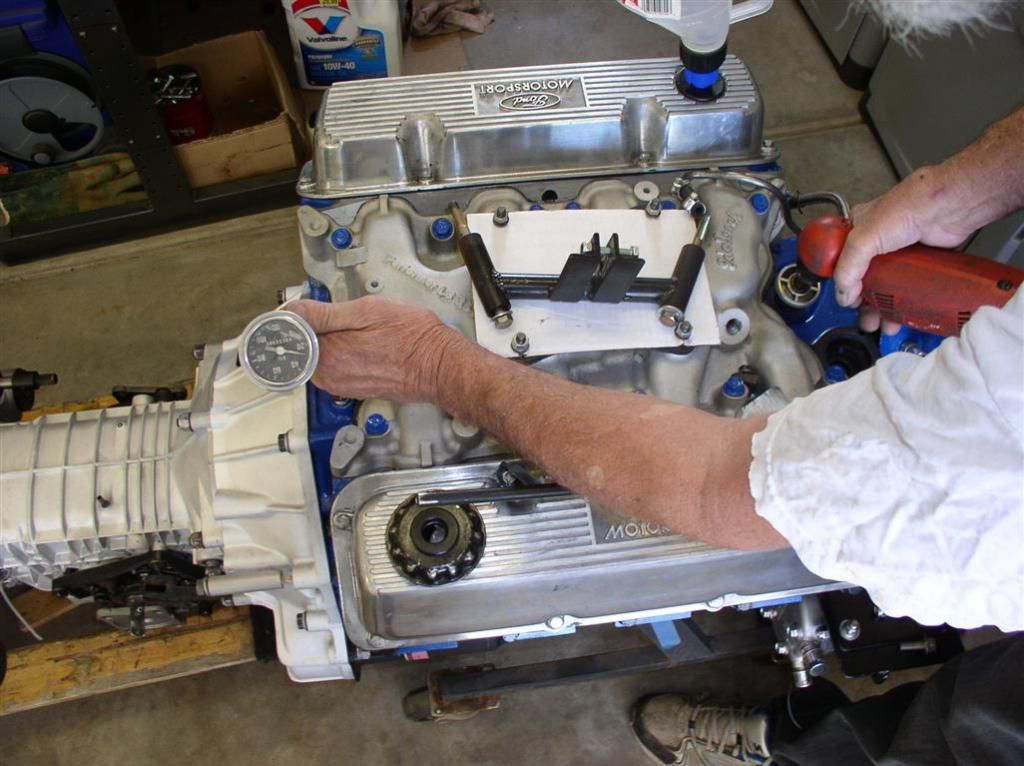

My project started as a new motor build, with upgraded performance goals. I wanted to "freshen up" the stock engine, and give the car more power, but retain the classic, stock lines.

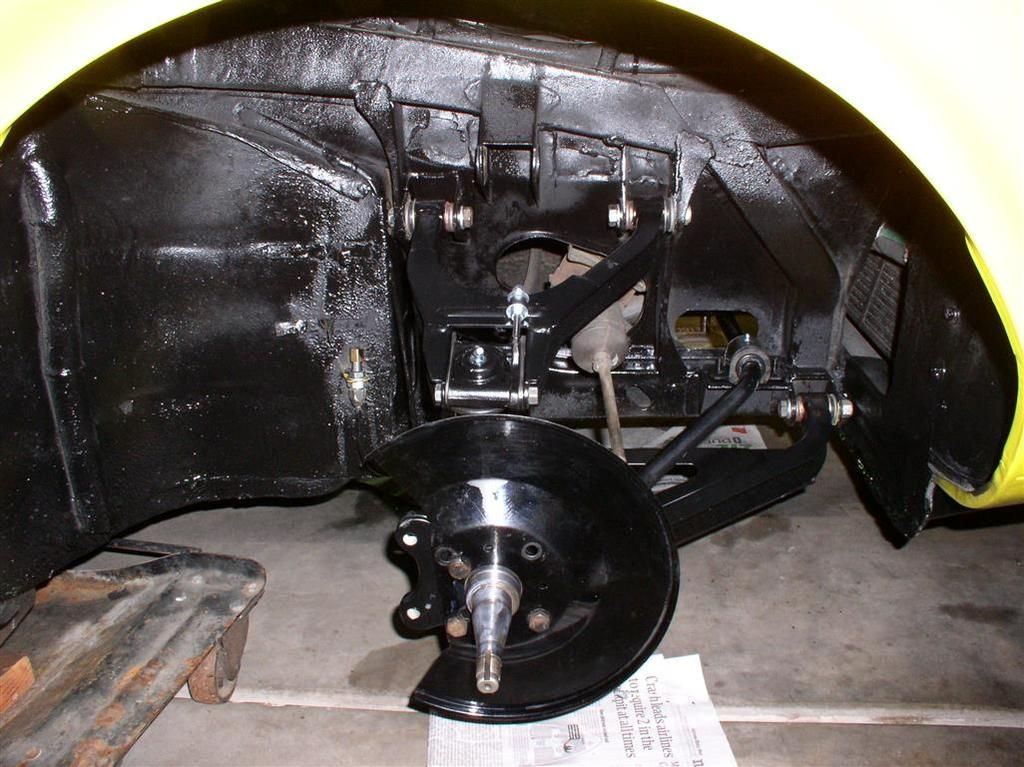

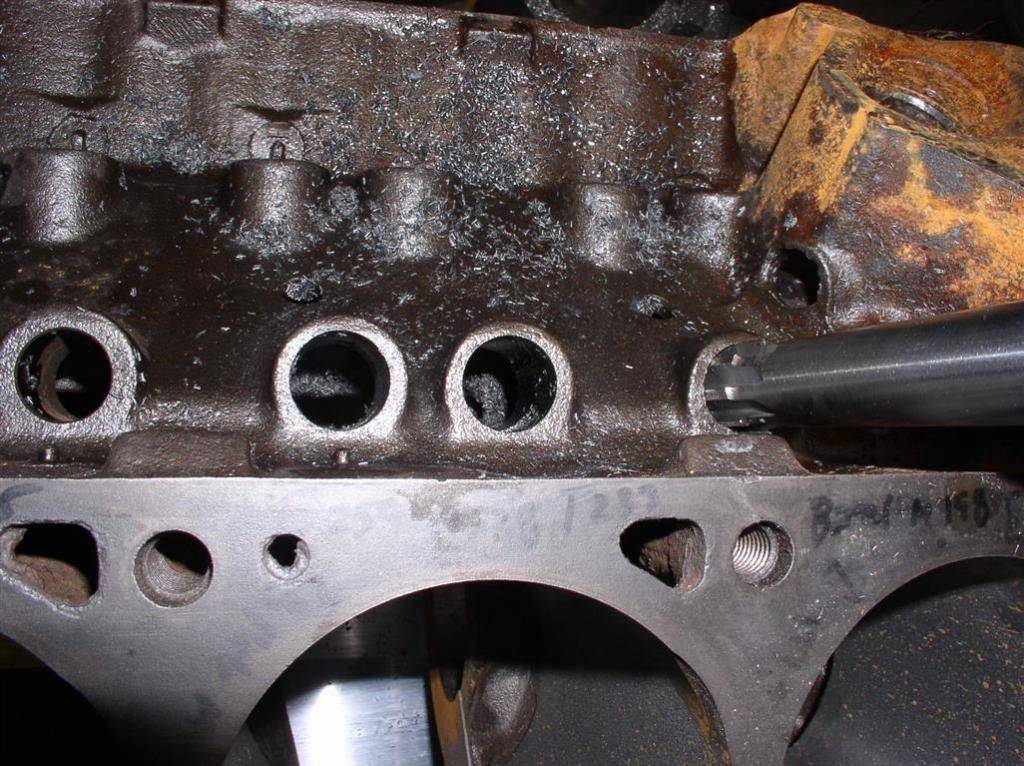

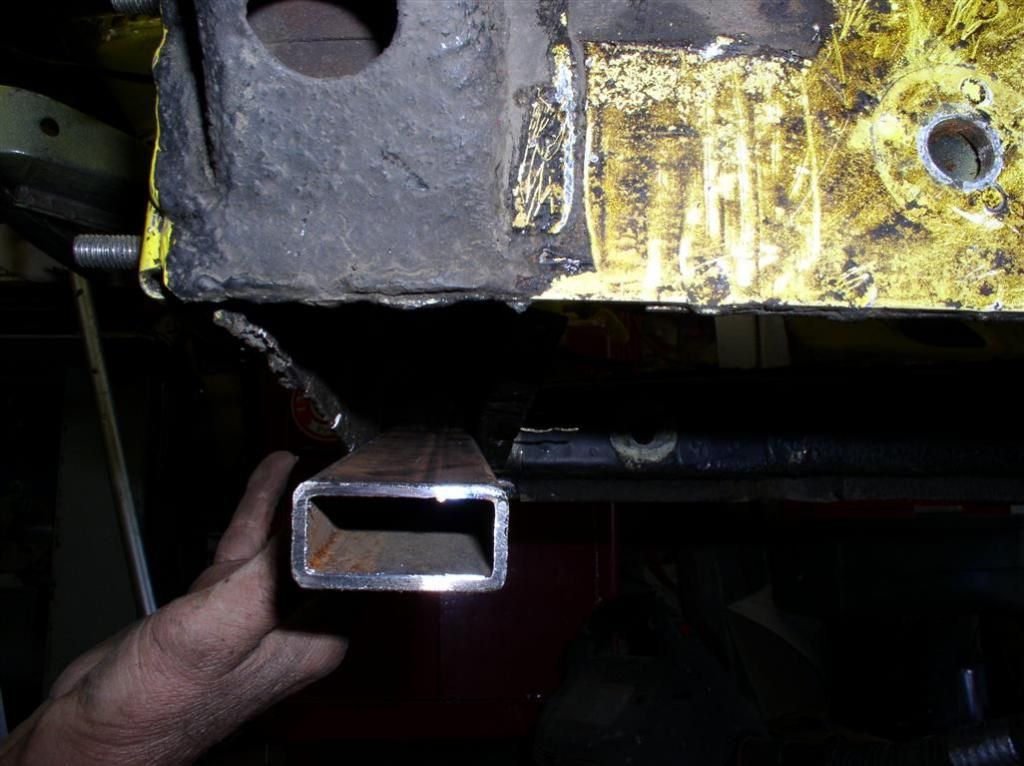

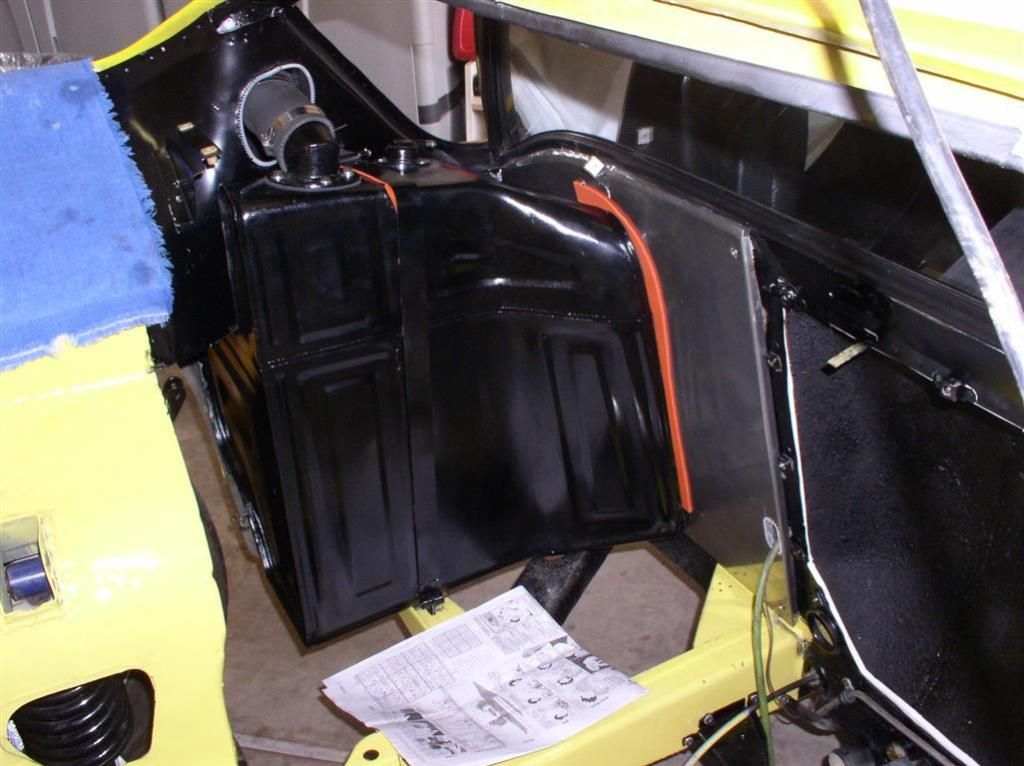

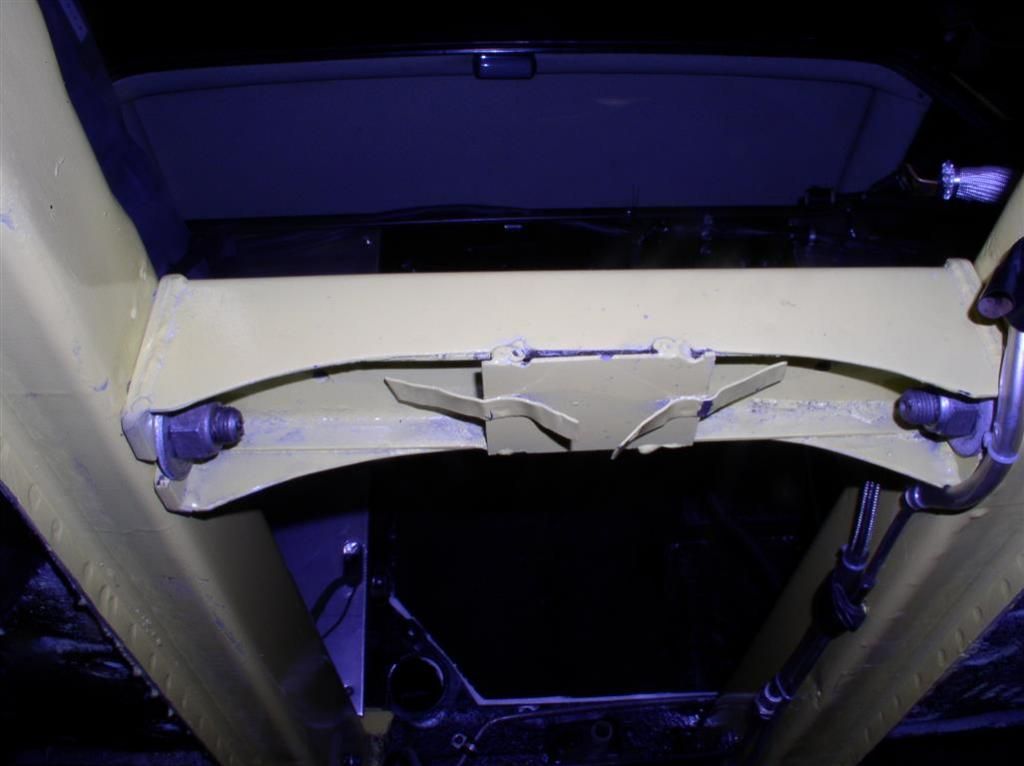

Once the motor was built (about Feb., 2014), I pulled the original engine. That was when the scope of the project really changed. Things I found, and upgrades I needed boosted the scope beyond what I was expecting, but it all needed to be done. If you are in for a dime, you are in for a dollar!

My wife (first and only) was surprised by the workload, but what can be done?

I am far along, and I can see the light at the end of the tunnel. Hope you enjoy the pictures, and the details of my build progression.

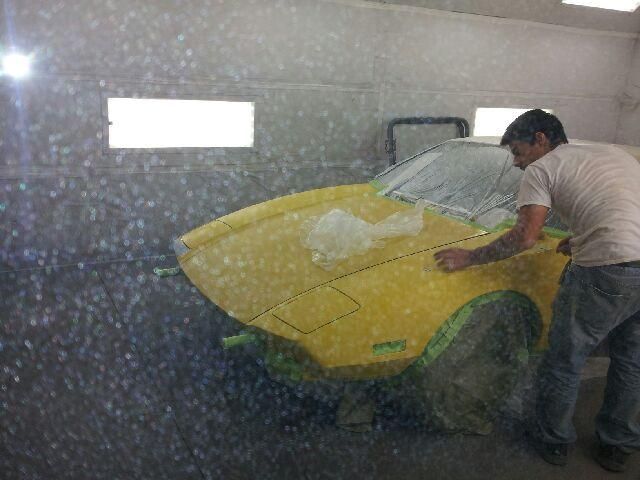

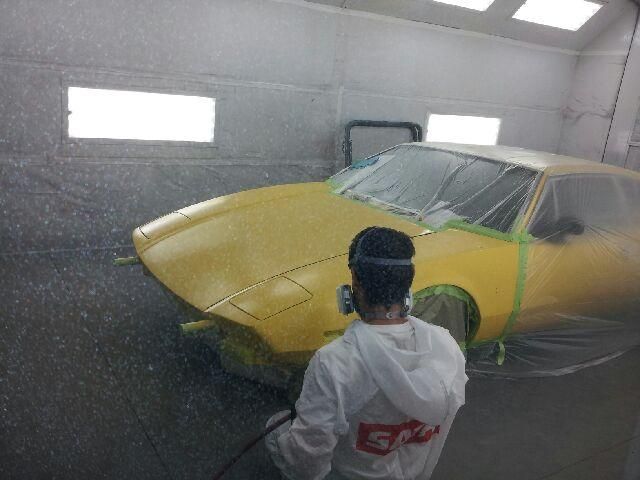

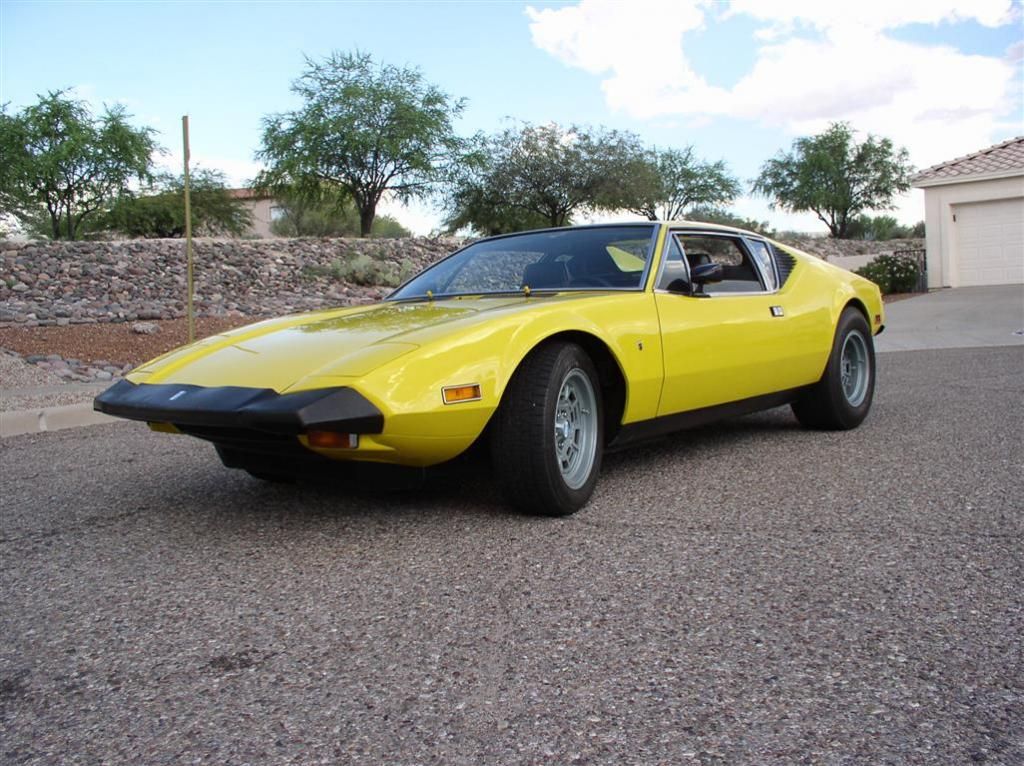

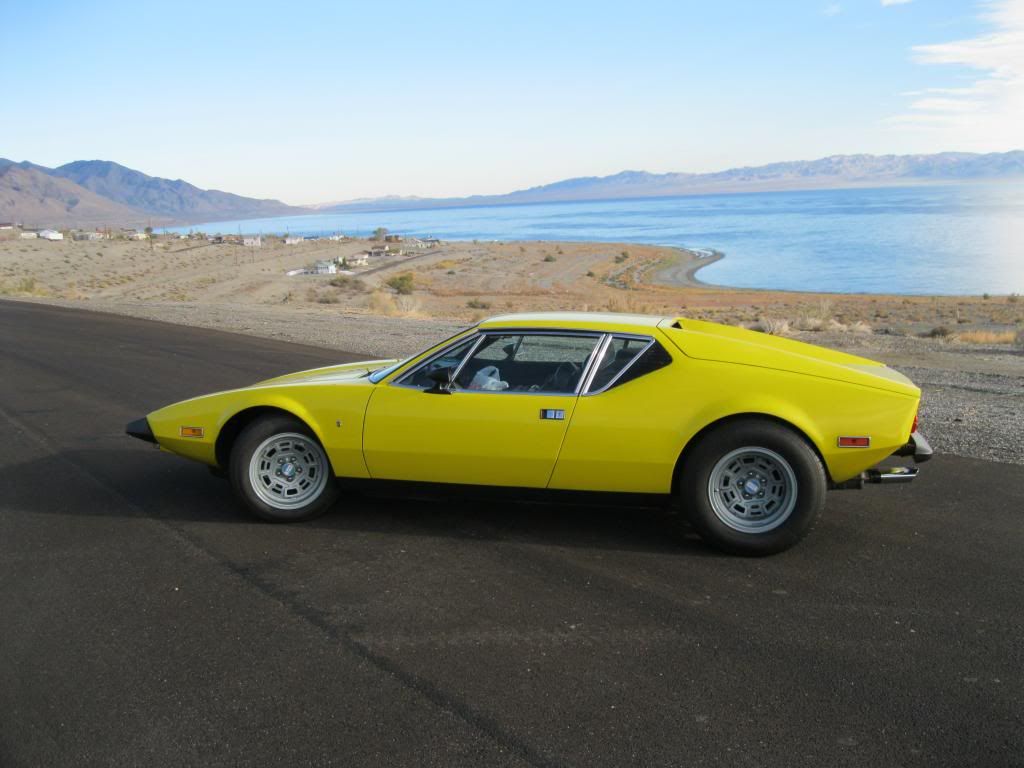

Here's my car before the resto. I'll try and shrink the pictures in future posts.

[/url]

[/url] [/url]

[/url] [/url]

[/url]

![photo 06-17-20141Medium_zps3b9d943d.jpg~original[/IMG] </a><BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20141Medium_zps3b9d943d.jpg)

![photo 06-16-20145Medium_zps83eaaf0f.jpg~original[/IMG] </a><BR> <BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-16-20145Medium_zps83eaaf0f.jpg)

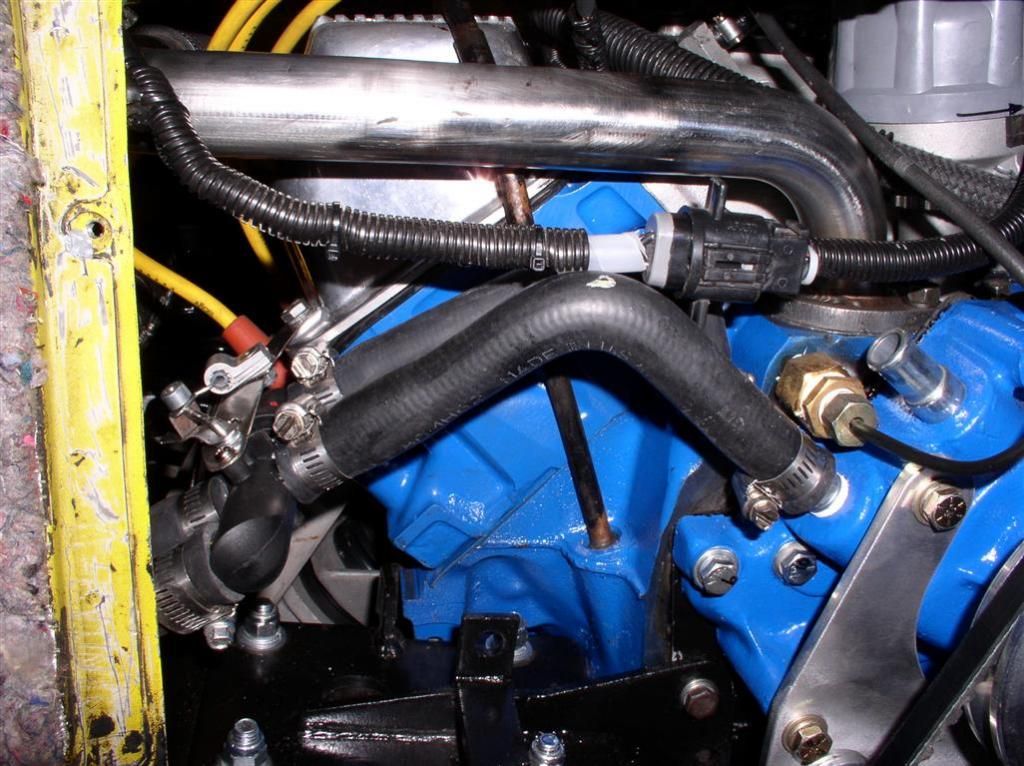

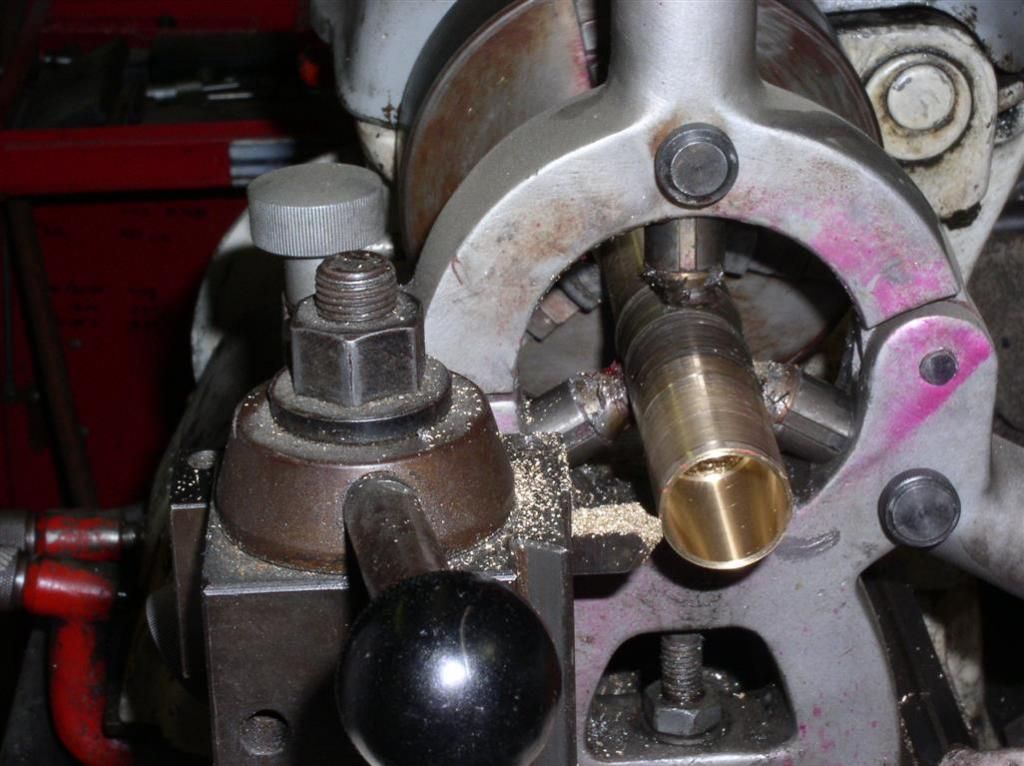

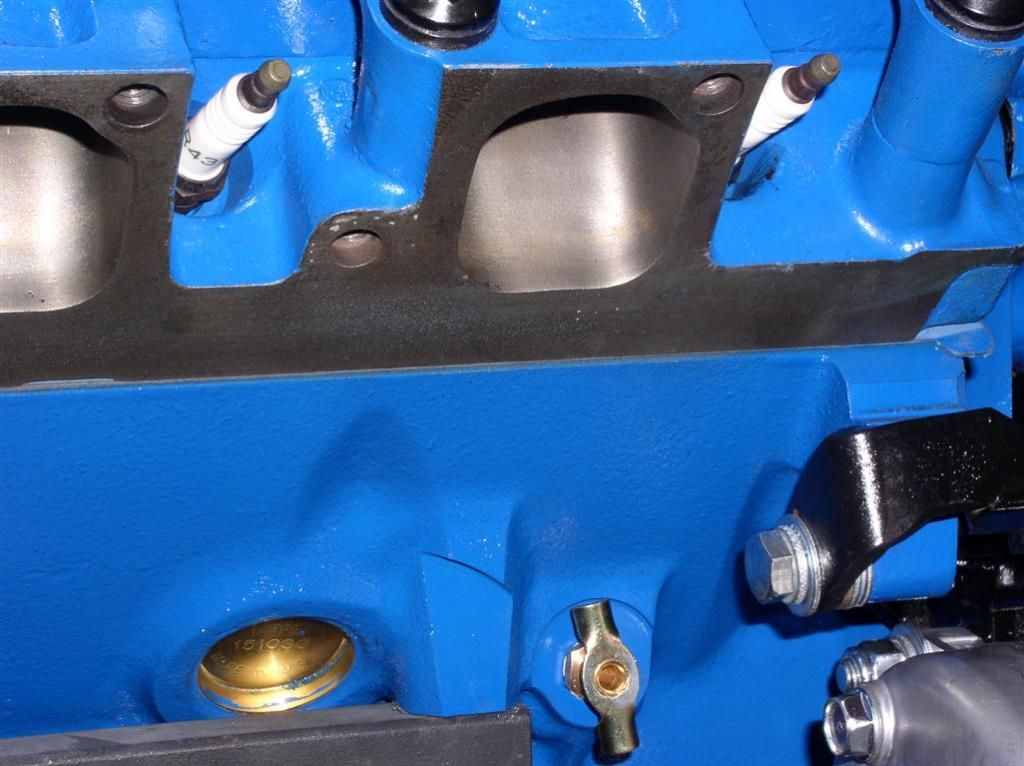

![photo 06-17-20144Medium_zpsfe354a8b.jpg~original[/IMG] </a><BR><BR>The header attachment bolts were machined with a locating boss in the bolt flange. This allows a more positive header alignment, and helps to prevent the bolts from loosening up. It's a little tougher to see in these pictures.<BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20144Medium_zpsfe354a8b.jpg)

![photo IMG_1229Medium_zpsb3289aa1.jpg~original[/IMG] </a><BR><BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/IMG_1229Medium_zpsb3289aa1.jpg)

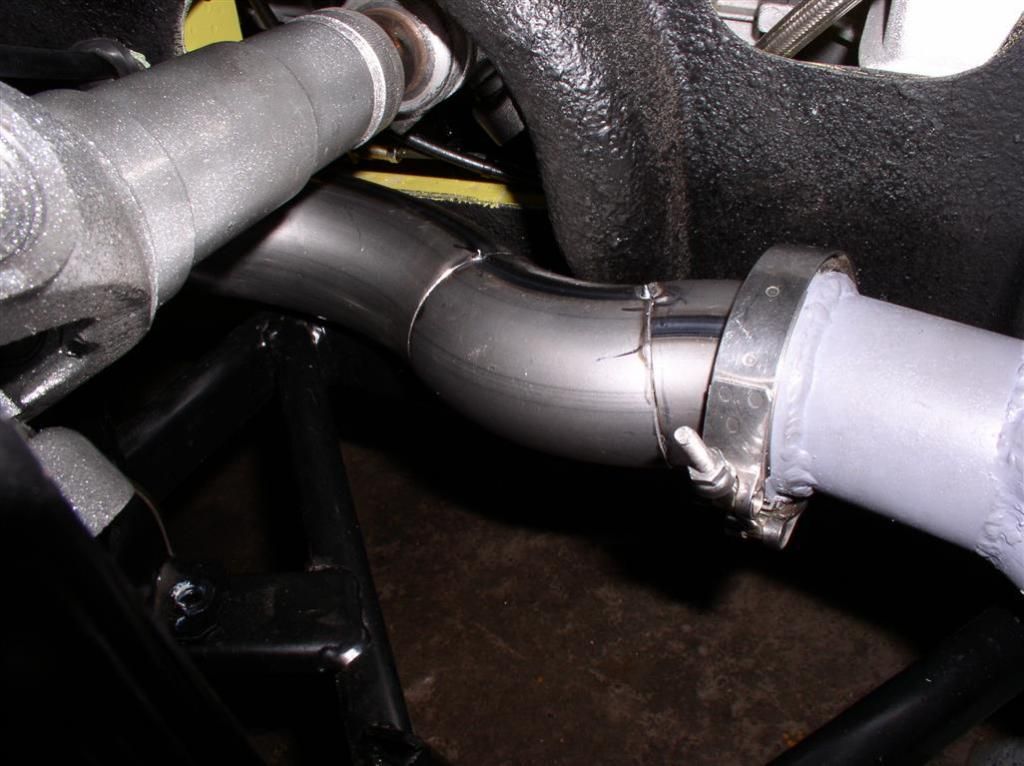

![photo 06-17-20148Medium_zpsa943d280.jpg~original[/IMG] </a><BR><BR>Tubing to the mufflers will be upgraded to 2-1/2](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20148Medium_zpsa943d280.jpg)