There is a difference in the clearances you ask about between the types of dash the car has, i.e., the dual pod or the single pod. In fact, the version of the single pod that the European market cars is a little different then the plastic version used in the '74 USA cars. The Euro version is a pretty thick fiberglass.

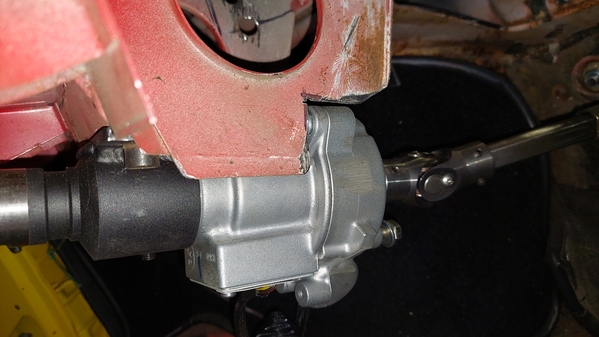

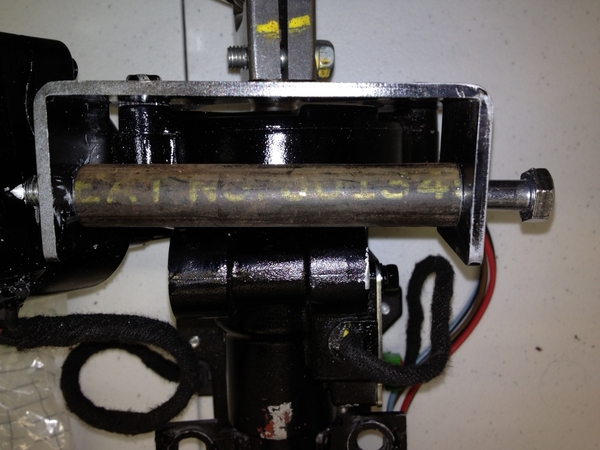

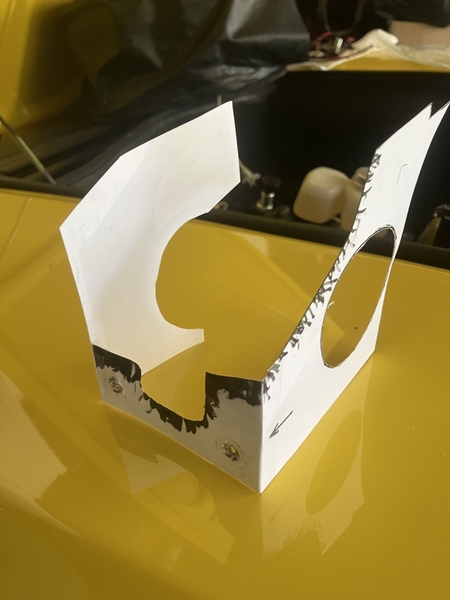

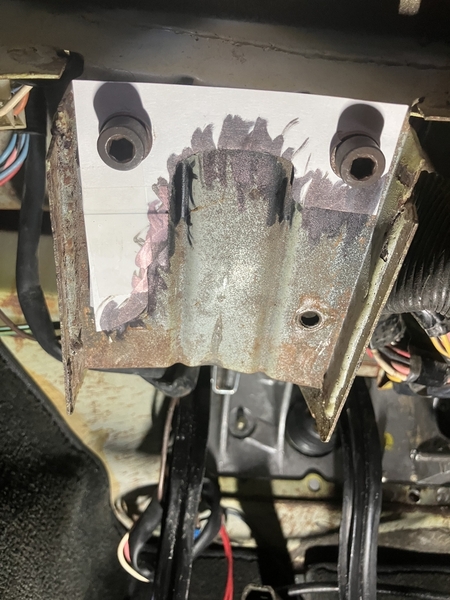

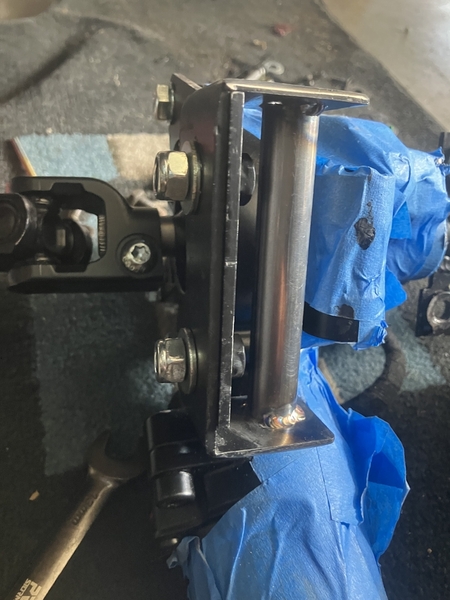

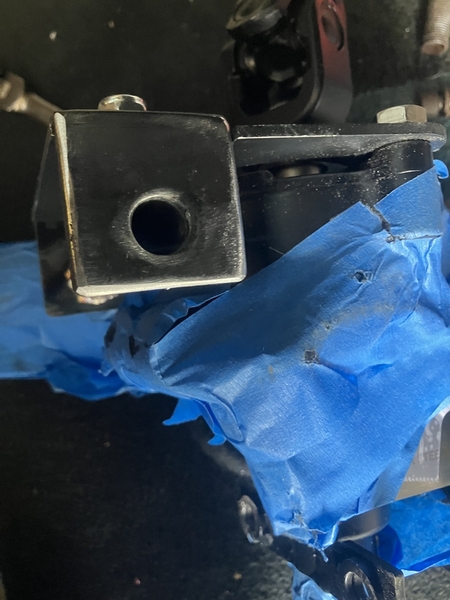

The front mounting bracket in this case (EPS installation) really needs to be made with slots (about 1" long) rather then single round holes, so that there is some adjustment, in and out (front to back).

It also needs to be made so that the wheel mounts as high as can be with no shims and able to be shimmed down to adjust the angle to your liking with bolts long enough to accomplish the adjustment. To me that is obvious and an indication that sufficient experimentation was put into the design process.

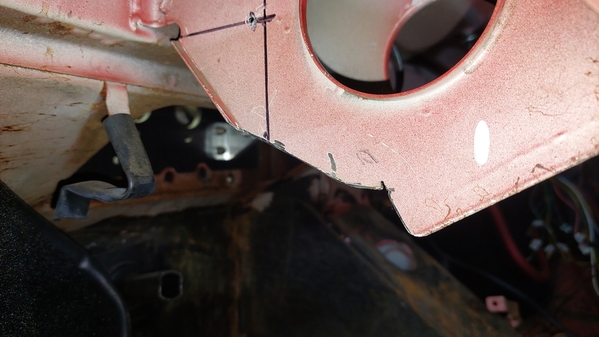

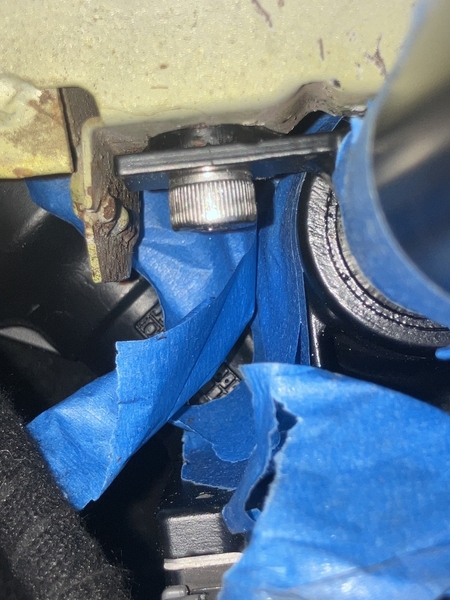

The left rear mounting bolt is the toughest one to get in, no question. In my case I had to use a flanged hex head bolt where I used Allen socket bolts in the other three spots.

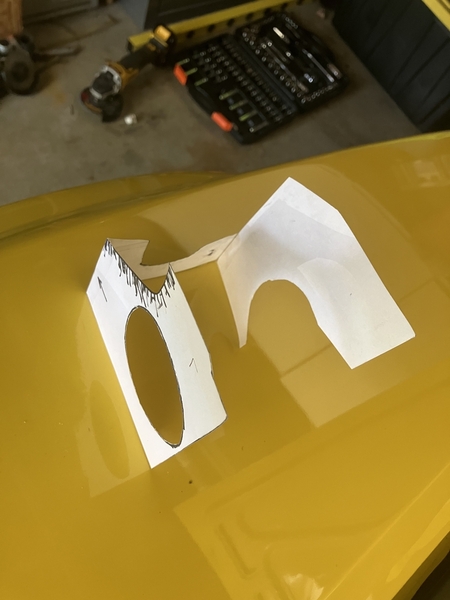

That is actually a back and forth process where it is necessary to modify the new bracket in my view. My mounting bracket started as a square plate with four holes. Then evolved into slots for adjustment front to back.

This is probably the toughest part of the fit to the car. The trimming of the sheet metal is very minor in comparison.

I actually went through that (adjusting the closeness to the dash) before the EPS developed (or ever existed yet) in that I was going to a Momo steering wheel and the adapter gave more room and I wanted the wheel closer to the dashboard so I had remade the mounting brackets with slots.

This actually showed in the angle of the directional signal rod in that it needed to be bent more for clearance to the dash when in the "high beams on position".

In fact, at one point I toyed with the idea of the telescoping column like the Corvettes have, but since I am the only one who drives the car I just set the location to where I felt most comfortable. In my case, that was as tight as I could get it to the dash board...but my thought is that the new column mounting bracket needs slots and that what you have is just plain an oversight.