“ some say, I know two facts about DeTomaso Pantera Powersteering - and both are wrong” (I’m sure a few of you know where this came from… Lol)

i’m using my C7 Corvette (which will be substituted by the Pantera) as a daily driver, getting groceries running errands, bringing children to school and picking them up! Now, for all of you who do the same “job” you know how packed the parking lot at the grocery store can be or all the perfect driving parents (soccer moms ) at the school just try to annoy the hell out of you!

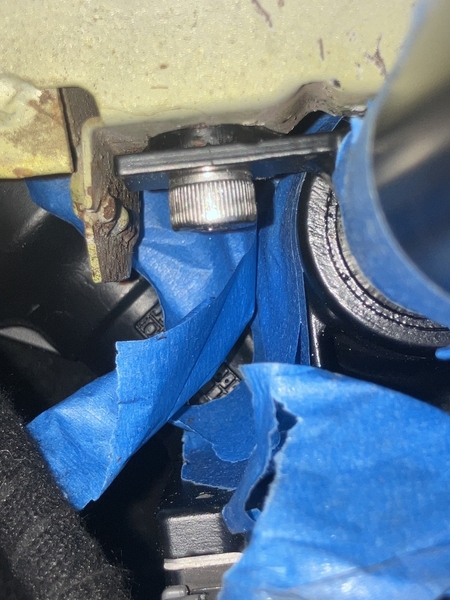

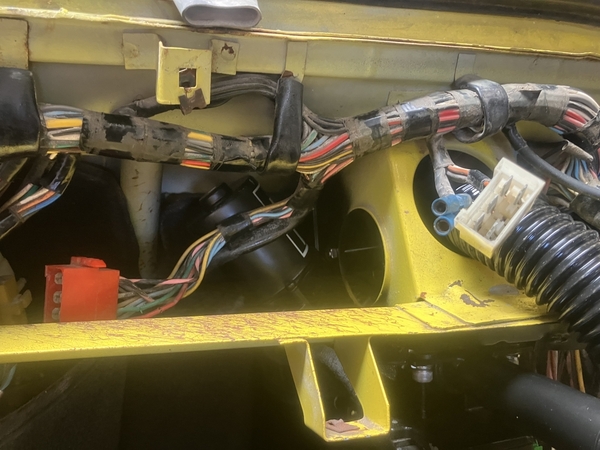

In the extremely short period I drove the Pantera, I did notice that the steering was quite heavy, at least for me…(I’m not Working Out, skinny, slinky, tall guy… That’s me!) I know it would annoy the hell out of me as well. If I have to do it early workout every day to zip in and out of parking opportunities..The solution was obvious… Work smarter, not harder! Powersteering it is!

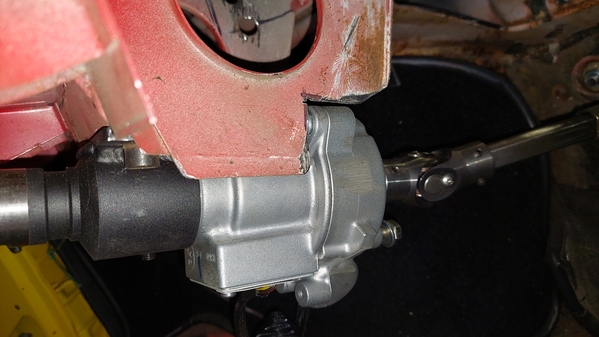

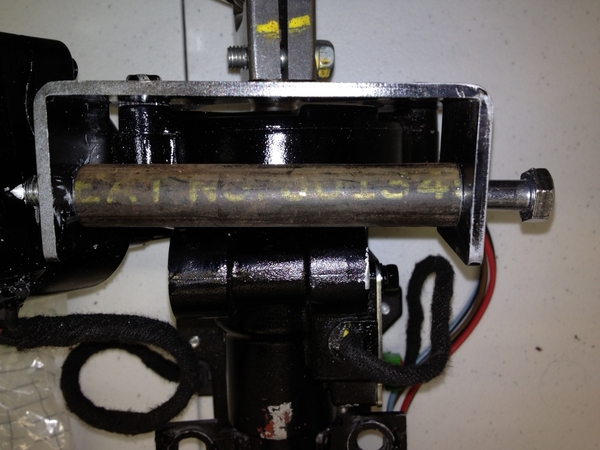

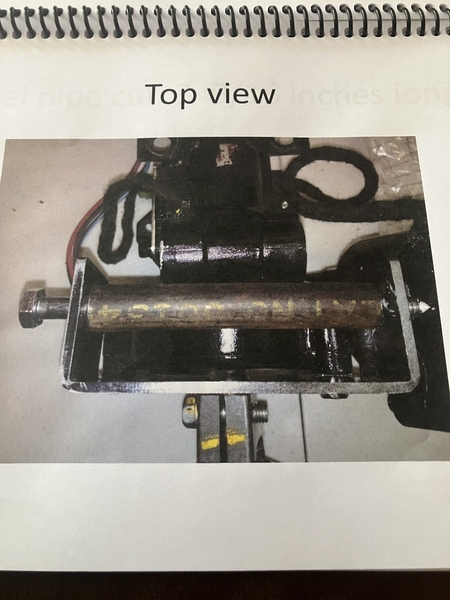

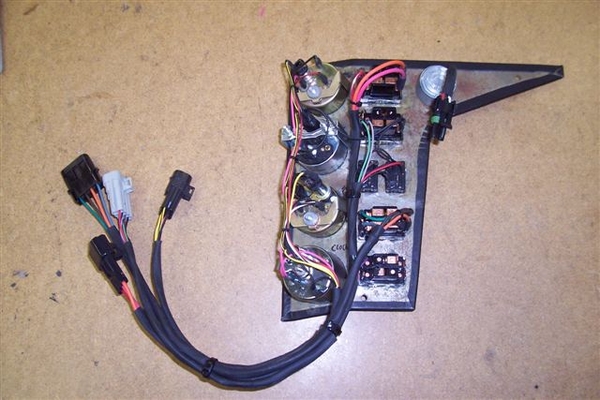

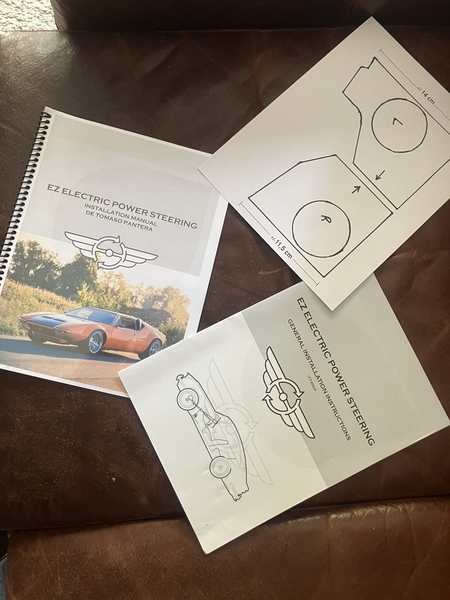

it seems that two predominant options are on the market, one is from SACC and one from EZ electric power steering from the Netherlands. The main difference between those two is SACC has a knob you can regulate how much Powersteering support you want, while the EZ has a sensor that is hooked into the speed drive, and automatically turns down the support of the Powersteering support related to the speed… The faster you go the less support you have! From the overall arrangement both look about the same, I think the EZ electric motor is a little bit smaller, but as it said before, I might be wrong! to make a long story short, I know myself, and I know if there’s a knob I can turn to influence whatever it is, I will do it! Probably do it a lot… (small example for people here who have been in aviation: multi probe CHT – EGT but single read out and cylinder selection knob…i’m surprised there was any knob left when I sold the airplane)

well, that’s the hint to what my decision was!

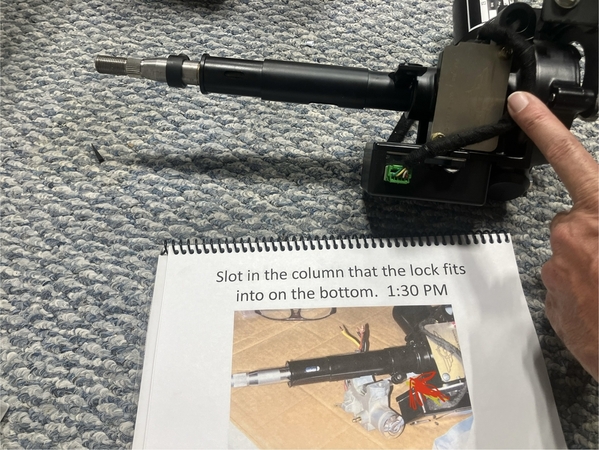

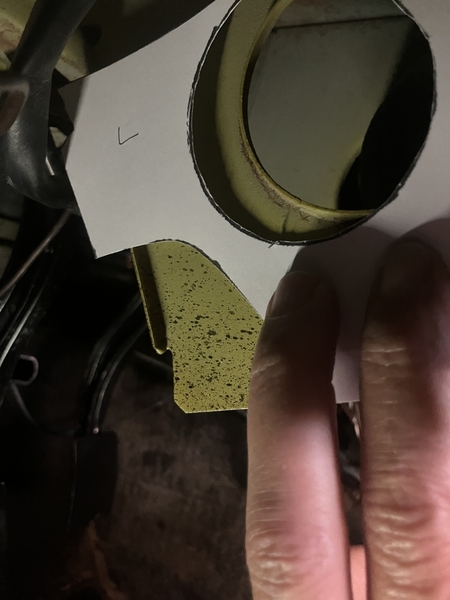

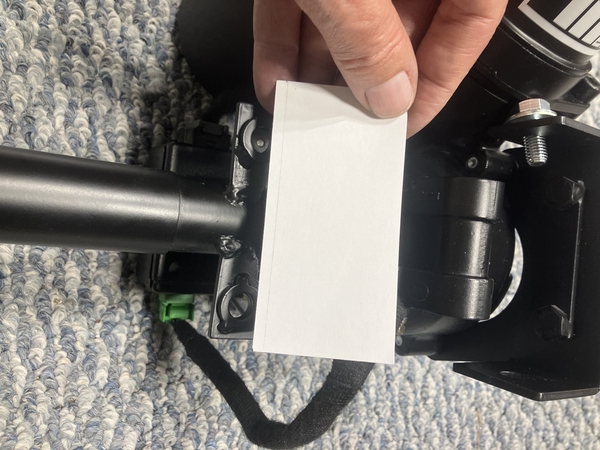

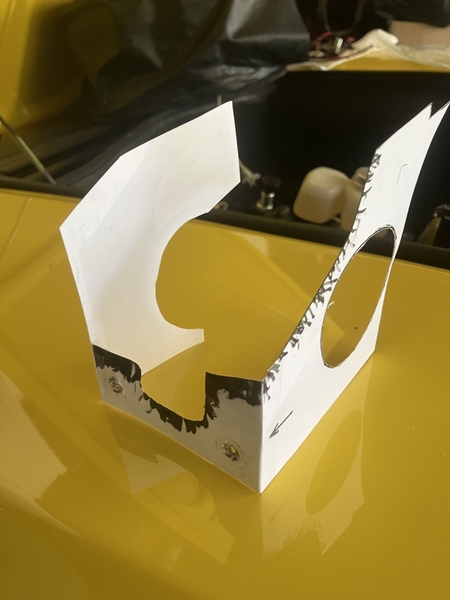

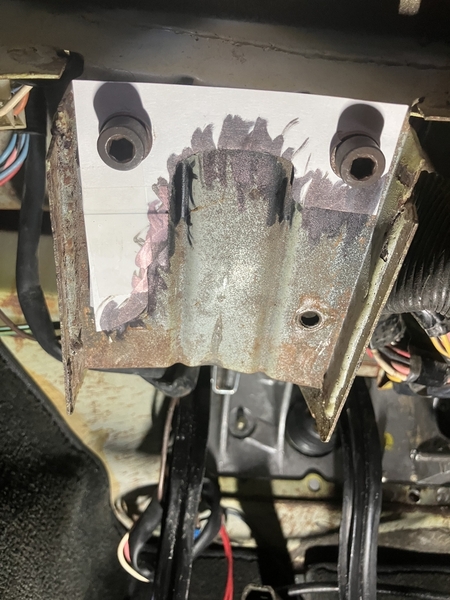

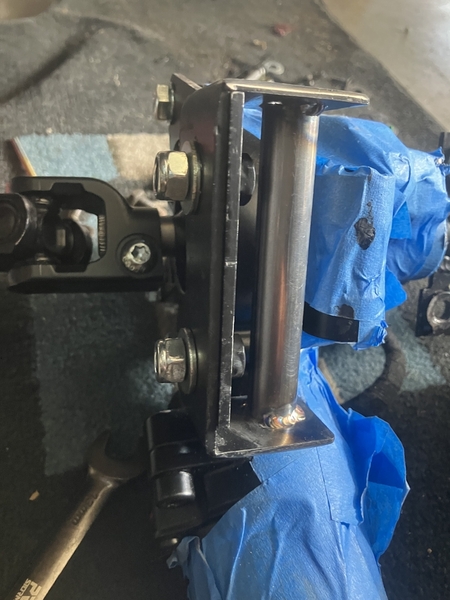

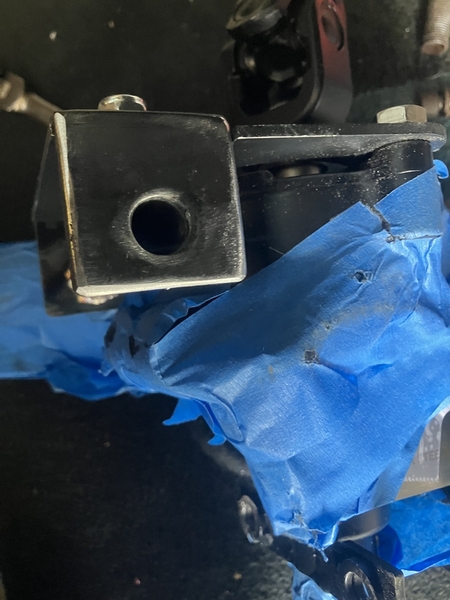

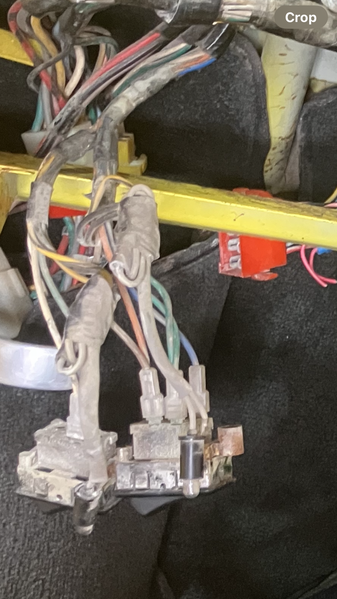

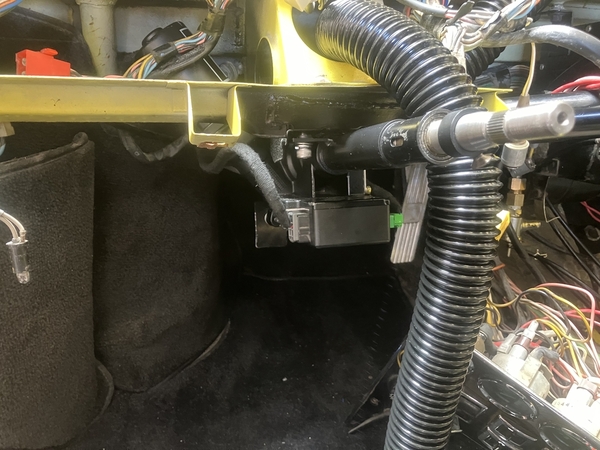

I put the lighter next to it so you have a reference of the size of the motor!

I put the lighter next to it so you have a reference of the size of the motor!