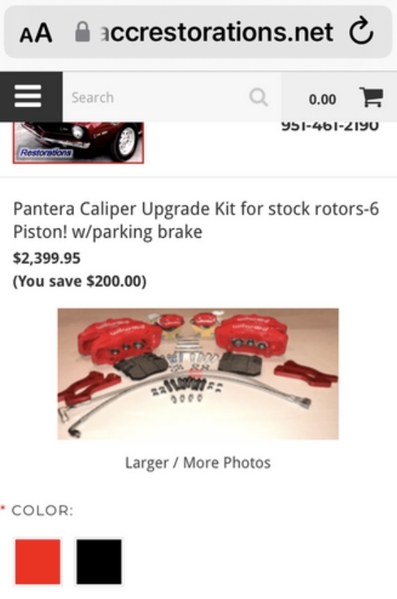

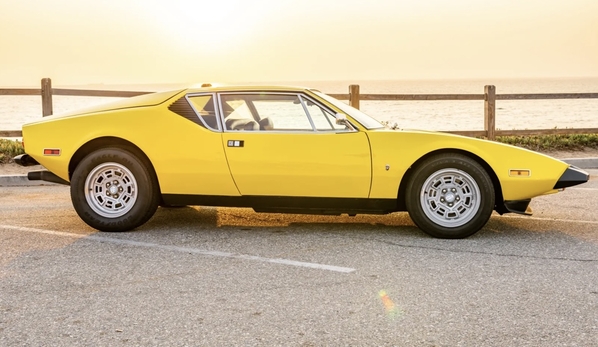

I decided on upgrading my brakes to the from SACC offered Wilwood conversion 6 piston with separate parking brake caliper. My main reason was that i can keep the original rims on the car…. I like the look of the 70’s balloony’s… and with the calipers in black it will not be very noticeably!

Replies sorted oldest to newest

I ordered the brakes a couple weeks before x-mas and I had them on my door first week in January… great service.. thank you Scott!! (But you know it takes a village to raise a Pantera.. more people to enter the stage LOL)

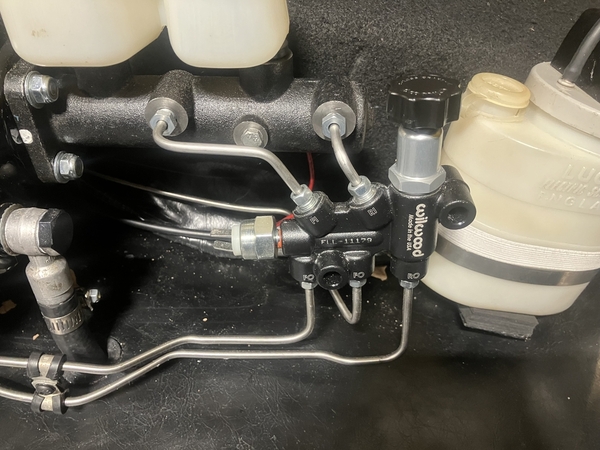

Backing up a little - I replaced the booster, brake and clutch master cylinders, proportioning valve, and the brake lines to the front and the first 20 inches to the rear stainless steel.

obviously I ripped the glue in carpet out and fixed the destruction caused by leaking brake fluid from the last 50 years !! After that i glued down 1/8 inch closed cell foam and topped it off with vinyl. Easy to clean and nothing gets underneath!

I found a proportioning valve from Wilwood that has a built Y for the front brakes, master cylinder to left and right caliber and adjustable pressure for the rear! It even has the brake light switch! I have to trace the wires because in the last 50 years someone installed a mechanical switch at the brake pedal… undo that!

Also I want to point out that the hose for be vacuum to the brake booster was very soft because it was soaked in brake fluid for a long time - replaced that too!

Attachments

Going into the project with full steam (after reading the instructions obviously) jacked up the front of the car, wheels off, calipers and flex line off (kit comes with new steel-braided lines) without the mess because still empty after the brake master… The instructions, talk about that the backing plate has to be trimmed for the new calipers to fit so I test fitted the caliper and made one nice straight cut! Nothing special or elaborate because I don’t want any small “ear” to vibrate. Break backing plate distance on the bottom, and on the top of about the same to the brake, caliper - easy cut without taking it off, deburred with a file, little paint on the edge. The backing plate acts supposedly as a heat shield to protect the rubber covers over the joints right next to the disc…

Caliper sits center to disc, adapter is perfect, comes with Allen head bolts. After that I put the 15” original wheel on and checked for clearance and it’s more than 1/4”! All good! Till now…..

Attachments

Now the bad things I found:

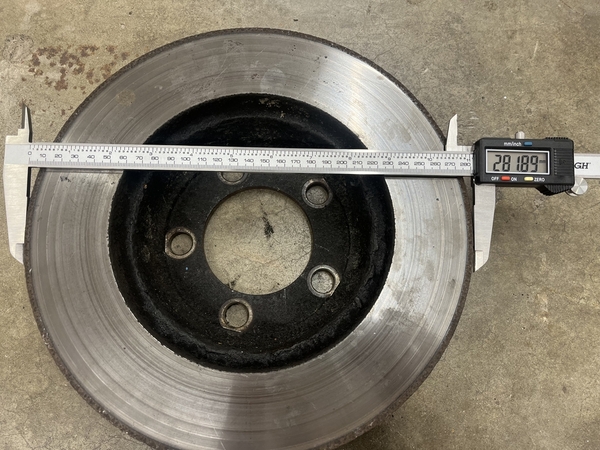

my brake discs are already turns down to 19mm - which is minimum thickness for the rotors! I am sure this was not done because of wear but because of rust! If you look at the rust scaring on the rest to the rotor and being original ( even small DeTomaso logo cast) and 50 years old and a bit over 30k miles . And at some point the disc seems to got clamped into a vice leaving clamp marks on the brake surface and 2 sharp “cuts” on the outside corner above! Also the axle nut were destroyed when they where beaten into the grove of the axle stub for safety. Things I have to address before I move on with the project. I am very surprised that no vendor has original brake discs made for the Pantera….

The new brake pads run at the very edge of the original rotors.. Doing some major cleanup and press the studs out…

Do anyone have source and part# for the wheel bearings NOT China made! SKF or so?

Attachments

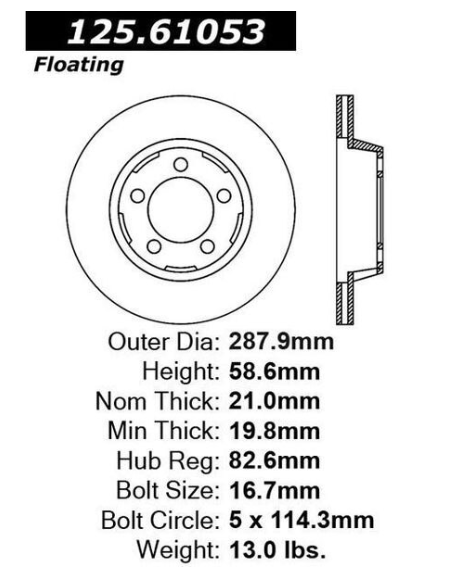

If you need to replace your rotors heres a great option and direct swap with the OEM rotor, but its got some upgrades. Mike Drew got with the people at Centric/Stop Tech and got them to make these for the Pantera Community. For many years owners were trying to find Mustang rotors that allowed the wheel bearing hub to fit on a replacement rotor, some found ones that had the bearing mount directly cast into the rotor while others got items that did not work, it was a nightmare. These solved all the problems and were improvements over the stock OEM design.

StopTech 125.61053 Premium High-Carbon Brake Rotor

They are also vented and should work great for what you are doing if your rotors need replacing.

Here's the Amazon listing for these rotors:

https://www.amazon.com/gp/prod...PDKIKX0DER&psc=1

Attachments

tomsealbeach

Just confirming that those rotors work for front and back on our cars? Looks like a good deal. As anyone used them?

No they do not work on the rear, rears are larger, but definitely on the front. I have them and as I mentioned Mike Drew (do you know of Mike?) worked with Centric/Stop Tech to build these for our cars because so many owners could not find replacement rotors. Mike has them his GF's car and also Chuck Engles has them. There are a fair number of other owners, I just can't name them. There is discussion back in 2017-2019 on the detomasolist about these rotors. Here's a snippet from that discussion: "Centric offers a dizzying array of options, starting with a plain, standard OEM-style Mustang rotor, all the way to a cross-drilled, slotted, cryogenically treated rotor (slotting makes them handed, with different part number for left and right)".

I spent a bunch of time trying to find the slotted, and cross drilled versions and was unsuccessful. When I bought these rotors I paid about $50 a piece. I spoke directly with the support people at Centric/StopTech and they could not direct me to the cross drilled or slotted versions, so I just got the standard surface, but they are vented and a fair improvement over the OEM solid rotors. The part number I posted above is the only one I could find.

Here is a picture of the slotted vented rotor that Mike put on his girlfriends car.

Great…. I give it a shot!

I ordered (that’s the beauty with Amazon, if it doesn’t fit, just return it)

StopTech 125.61053 Premium High-Carbon Brake Rotors

I’m just asking myself why on their websites they do not list any products for the Pantera…. And on Amazon, there are no dimensions …

just spoke to customer support and they don’t know anything about it.

The part number / rotor is generic for Ford mustang, falcon, comet, and such

I keep my fingers crossed. Maybe I got lucky!

Found these dimensions. There are other places that offer these for sale that do show the dimensions.

Attachments

Well, we find out soon… supposedly arriving on the 17th…

Till then I go for the rear brakes

(I wonder what surprise is waiting for me)

I do not believe that these are the exact rotors that Mike Drew ordered. I used these on the front of my car and found that the OD was too large. I had to machine them down to fit the stock calipers. Once I machined them down, I sent them out to be rebalanced since the balancing is done by removing material on the outer diameter of the rotor. That said they probably will work on the rear and may or may not clear the WilWood calipers on the front. One thing to note is that the holes for the wheel studs are not sized for our metric studs. The holes need to be bored out a little to fit, ~17mm as I remember.

…..and the plot is thickening….

Maybe I missed this at the beginning but the SAAC system was designed to be used with stock rotors? Or are there modifications to make them work?

I bought some from Rockauto, it's Centric reference 125.61053 and designated for "1966 FORD MUSTANG 3.3L 200cid L6". They mount in place of OEM discs without any modification. I paid $34.60 per unit for them in 2019.

Attachments

Yes the Sacc calipers in this tread is designed for stock rotors, but the six piston calipers can be adapted to larger rotors by repositioning the caliper with a slightly different adapter. These calipers should have no problem working on the rotor I posted above, its just redesigned slightly with venting, and much better metal than our stock rotors.

Rene Rock Auto still has them. $49

Thats a great deal.

Tsolo, below is the email I got from Mike Drew. Not sure what else to say.

Note that this is a direct bolt-on replacement for the stock solid front rotor, using the stock Pantera hub and studs. It is microscopically larger in diameter and has nominally the same rotor thickness but the offset is different by a few thousandths of an inch. However, the stock Pantera design features a goof which required them to correct the mistake with a shim between caliper and spindle to center the caliper over the stock disc. By happy coincidence the change in offset is exactly rectified by simply leaving the bandaid shim out.

I believe the part number to order the disc above would be 125-61053CSR and 125-61053CSL for right and left sides, respectively. They might have to be custom-ordered with the slotting as I had to do, but the plain non-cryo non-slotted rotor is readily available with the basic 125-61053 number.

As for pressing the studs in? You didn’t have to pay to have them pressed in. Just assemble the studs, rotor and hub assembly as much as you can, then get open metric nuts of the appropriate size, and some washers. Install the washers and torque the nuts to 80 ft/lbs. This will draw the studs in until they fully seat.

You could also accomplish this simply by bolting on a wheel and torquing the lug nuts.

Mike

These are the rotors I purchased.

@marlinjack the $2400 got me four 6 piston calipers (different bore front/rear) and separate parking brake calipers! The brake master is 1” or a bit more (1/16 or 1/8). The original front brakes supposedly are not bad but got dialed down because of the inadequate rear brakes…. So with the proportioning valve now in the rear circuit I think the brakes should work quite well. I’m not putting the car on the track, I’m just a “spirited” driver and would just hate to run out of brakes while knowing the issues beforehand. Also a better parking brake would be nice and if the front discs I just ordered are workable-GREAT! I wanted to keep the original rims because I love the look! The car reminds me so much of the Maserati Bora I drove for a while

I bought this car #4679 just a few months ago and drove it for one mile and put it in the garage and start getting over the car… 30k miles in 50 years is just bad (80 miles in the last 8 years) for everything!

electric switches, electric motors, engine, transmission, gas tank, cooling system…absolutely everything… And I go through everything! And more… like moving the gas filler to the outside…..

not trying to do a restoration. I try to get all done say by end of February and I’m one happy camper !

Here are some pictures to prove my point. Take it for what you will. LeMans850i can confirm when he receives his rotors.

Note the manufacturers dimensions above

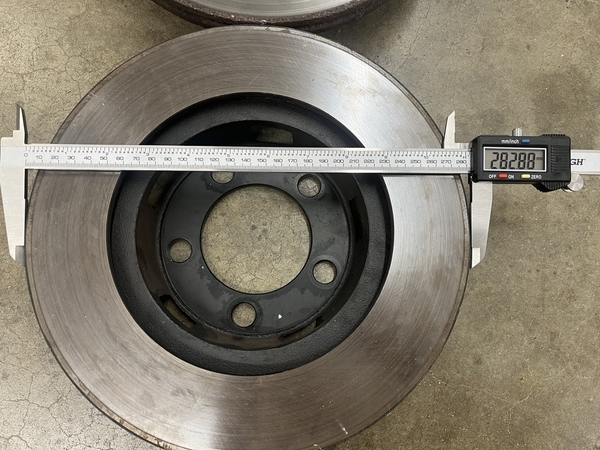

Here is the stock front rotor from my ‘74. Here is the 125-61053 after I turned the OD down.

Here is the 125-61053 after I turned the OD down.

Here is the stock rotor hub diameter.

Here is the hub diameter of the 125.61053. Note it is oversized compared to the original. The rotors will be stud centric.

Here I measure the stud hole on the 125-61053 after it has been machined to fit the stock wheel stud with a bore gage.

Here is the bore gage in the caliper.

Here is the factory stud shoulder measurement.

From these pictures you can see that I had to take 5mm off of the OD of the rotor. Without this the rotor dragged on the under side of the caliper. And, the factory stud will not register into the rotor unless the stud holes are opened up to 17mm.

Another issue is the thickness of the rotor flange. The stock flange is 9.2mm while the 125-61053 flange measures 7.75mm. The factory studs require a 1.5mm washer under them so that they do not protrude too far through the axle flange. If they do you could have an issue tightening your wheels because your lug nuts could run out of thread and bottom out.

I put a lot of time into this. If you don’t believe me, by all means feel free to try this yourself.

Steve

Attachments

@tsolo thank you very very much for your presentation!! I am looking forward to the discs and hopefully make them work and show the way and the results! You just contributed a major part to that!

Steve I totally see what you are saying. When did you purchase yours? I'm wondering if the original machining dimensions changed? That's bizarre.

Lemans 850i sorry if you have the same issues as Steve, my intent was not to open a can of worms and for you to go down a rat hole! Definitely let us know what you get. I will definitely delete my posts if these turn into a big PIA. Steve thanks for your input!

I believe that the manufacturer modified the final machining of the Mustang blank to meet the original Pantera specs for Mike when he placed his bulk order. These rotors can be made to work but require some machining and if you do it correctly, they should be rebalanced. But….. they work. I called every machine shop in town and only found 1 that could or would do the balancing.

Steve

Hey guys…. You all are very appreciated!

no need to apologize! I was googling and reading here for many hours but I could not find any conclusion for the problem at hand..

im hoping to finish this thread with definite information so the next guy has some guidance how to tackle the problem!

And all of you are important to get there..

I work on the car in my garage by myself and I don’t have a lifetime to figure it out..

just started another thread about the external fuel filler I’m building for it… you know, when I have a spare minute between brakes, electrical, fuel system, steering and and and..I’ll post threads once I got parts and ideas.. lol

im steamrolling through this project and you guys are a BIG help providing resources and information which would take days for me to find!

AND a big big THANK YOU to PI Motorsports… Jerry…can’t say enough good things about him!

Attachments

@tsolo posted:I believe that the manufacturer modified the final machining of the Mustang blank to meet the original Pantera specs for Mike when he placed his bulk order. These rotors can be made to work but require some machining and if you do it correctly, they should be rebalanced. But….. they work. I called every machine shop in town and only found 1 that could or would do the balancing.

Steve

What sucks is they are suppose to be "bolt on" and done! Wouldn't that be nice! Steve you are the first one that brought up having to machine these. Anything can be made to work with some fenagleing and jury rigging. ![]() But I guess we all know we're working with a 50 year old car, so some of this is expected. Thanks for your input here. I will certainly temper my enthusiasm on these rotors in the future.

But I guess we all know we're working with a 50 year old car, so some of this is expected. Thanks for your input here. I will certainly temper my enthusiasm on these rotors in the future.

When caliper to wheel clearance is minimal, make sure that there is enough clearance for adhesive wheel weights (if you use them) to clear the calipers.

John

Clearance is between 3/8 and 1/2”

Does anybody know what the original thickness of a new Pantera front rotor was? 21mm?

@LeMans850i posted:I am very surprised that no vendor has original brake discs made for the Pantera….

FWIW, Pantera Performance Center in Carson City, Nevada sells bolt on direct-replacement rotors.

Larry starts with a Porsche Brembo rotor and machines it to the exact dimensions for our Panteras. That makes vented, slotted, cross-drilled rotors available to us.

Not to be ungrateful for your help, but the casting says clearly the minimum thickness is 19mm!

If you convert inches to mm it gets you to 17 mm after refinishing it…

the curvature that goes from the disc to the hat is exactly flush with the disc at 19 mm thickness… I do not think you actually would machine it creating a sharp corner / stress riser in that area! 17mm is definitely not correct!

regarding the original thickness of a new brake disc I thought it may be 20 or 21 mm?!

I did see the machined Porsche rotors to fit the Pantera but the price was not anything I am willing to spend… Over $800 per disc?! if I remember correctly…

Attachments

My Centric/Stop Tech rotor is 20.98mm or .825" thick. The minimum thickness stamped on the rotor is 19.81 mm

Thank you

that makes sense!!

@LeMans850i posted:I did see the machined Porsche rotors to fit the Pantera but the price was not anything I am willing to spend… Over $800 per disc?! if I remember correctly…

Actually, PPC's vented & cross-drilled brake rotors (front & rear) are $350 ea. (I just checked the price 10 minutes ago).

Admittedly not cheap, but also not unobtanium. And it's a quality part!

now I can’t find them if my life depends on it …

could you please post the link…

edit: just called PPC… you are absolutely correct…

thank you!!!

p.s. still cannot find it on the website

Good news .. bad news….

here is the good news:

the discs arrived!!!!

bad news… the picture shows and I did call the company as well to verify it is only the disk - not the whole hub disk assembly!

….return to sender,

I was looking at it and thought maybe Machine the center out to have the right bore size 81.9mm and then Machine the thickness of the flange down to have the 9.2mm flange thickness… But the additional 1.5 mm are on the wrong side not centering the disk in the caliper so that’s not gonna work either. It would be just a cluster f@$&..

I think I’m gonna put the mustang to rest!

I don’t think Mustang is the solution…

(some may say “he gave up too early”, but I was reading a lot about that subject, and there were many many failures, and only not even a handful of success stories) . Just a few were successful with major effort and help from the manufacture of the disks… Not easily repeatable!

I’m going to order the disks from PPC... 350 dollars apiece 700 dollars for the axle … I want to see what I get ! one thing I really would like to see is the inside diameter if it has the proper fit going over the hub and center the disk! I think there’s a lot to ask from the studs, but not centering the disc permanently on the hub with the protruding cast for the bearings… The disc is not gonna just rotate, but when you apply the brakes, it tries to pull away from the center as well. Maybe I’m overthinking… Again…

Maybe I’m overthinking… Again…

I’m gonna see if I can come up with something better and more sensible but to get the Banana running Porsche discs it is!

I am bummed

Attachments

In a correctly dimensioned bolted assembly, when tightened to the correct torque, the studs do not work in shear but only in traction and the forces are transmitted from the rim to the hubs only by adhesion.

It is nevertheless preferable to separate the centering and fixing functions, but it is not essential.

Can’t quite tell since it is in the bag, but what you received is a one piece casting incorporating the hub and the rotor, correct??

Honestly, this is what I expected you to receive. The effort Mike Drew put in to have Centric provide just the rotors was a one time thing. Perhaps it can be done again?

I am running Mustang rotors at all four corners with Willwood four piston super lite II calipers. Functional but with some drawbacks due to diameter. I sourced them off of eBay sellers

originally the rotor and the hub were separate pieces and you can still find old stock rotors. It became cheaper and more efficient to machine hub and rotor from a single casting. I believe almost all the raw castings are made at two or three China factories,

Larry

Rene your Rotors came with the hub, bearings and the wheel studs! Thats surprising. I have the same part number and the rotor came bare!

@tomsealbeach posted:Rene your Rotors came with the hub, bearings and the wheel studs! Thats surprising. I have the same part number and the rotor came bare!

Tom, I am betting you got those rotors many years ago when they were still being supplied as separate rotors. Or you got them during the Mike Drew special order program.

Yes?

Larry