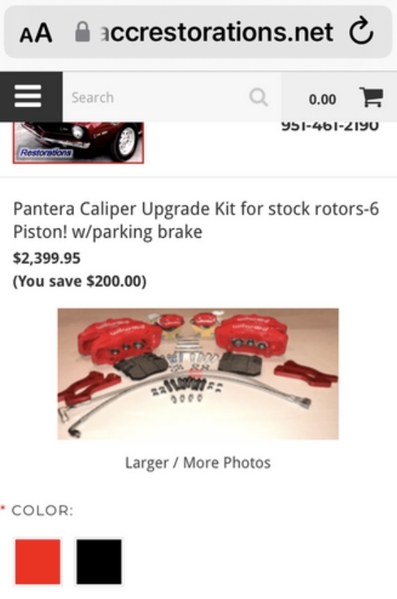

I decided on upgrading my brakes to the from SACC offered Wilwood conversion 6 piston with separate parking brake caliper. My main reason was that i can keep the original rims on the car…. I like the look of the 70’s balloony’s… and with the calipers in black it will not be very noticeably!

Replies sorted oldest to newest

I ordered the brakes a couple weeks before x-mas and I had them on my door first week in January… great service.. thank you Scott!! (But you know it takes a village to raise a Pantera.. more people to enter the stage LOL)

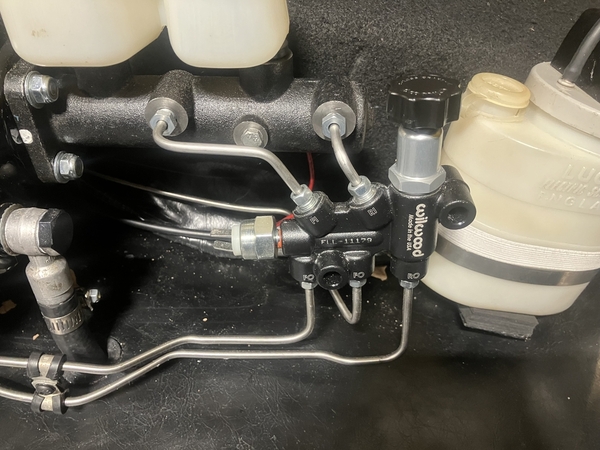

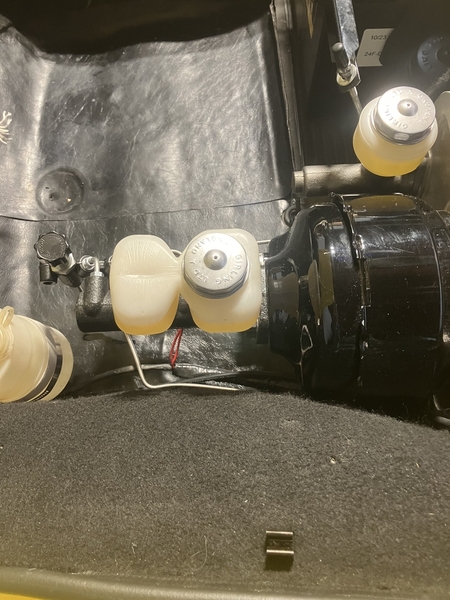

Backing up a little - I replaced the booster, brake and clutch master cylinders, proportioning valve, and the brake lines to the front and the first 20 inches to the rear stainless steel.

obviously I ripped the glue in carpet out and fixed the destruction caused by leaking brake fluid from the last 50 years !! After that i glued down 1/8 inch closed cell foam and topped it off with vinyl. Easy to clean and nothing gets underneath!

I found a proportioning valve from Wilwood that has a built Y for the front brakes, master cylinder to left and right caliber and adjustable pressure for the rear! It even has the brake light switch! I have to trace the wires because in the last 50 years someone installed a mechanical switch at the brake pedal… undo that!

Also I want to point out that the hose for be vacuum to the brake booster was very soft because it was soaked in brake fluid for a long time - replaced that too!

Attachments

Going into the project with full steam (after reading the instructions obviously) jacked up the front of the car, wheels off, calipers and flex line off (kit comes with new steel-braided lines) without the mess because still empty after the brake master… The instructions, talk about that the backing plate has to be trimmed for the new calipers to fit so I test fitted the caliper and made one nice straight cut! Nothing special or elaborate because I don’t want any small “ear” to vibrate. Break backing plate distance on the bottom, and on the top of about the same to the brake, caliper - easy cut without taking it off, deburred with a file, little paint on the edge. The backing plate acts supposedly as a heat shield to protect the rubber covers over the joints right next to the disc…

Caliper sits center to disc, adapter is perfect, comes with Allen head bolts. After that I put the 15” original wheel on and checked for clearance and it’s more than 1/4”! All good! Till now…..

Attachments

Now the bad things I found:

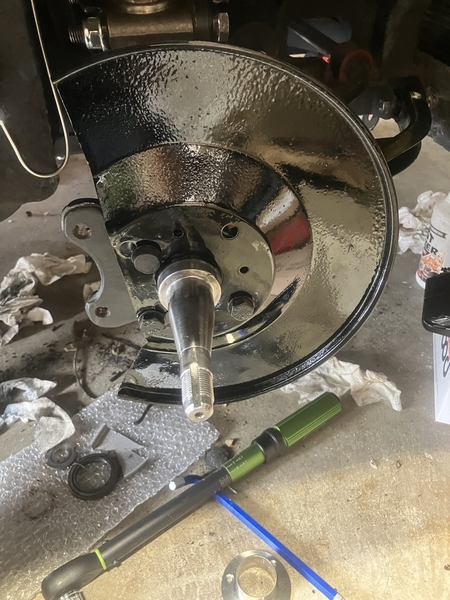

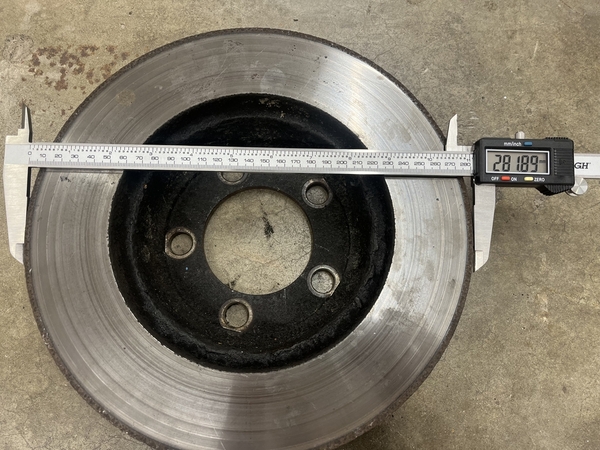

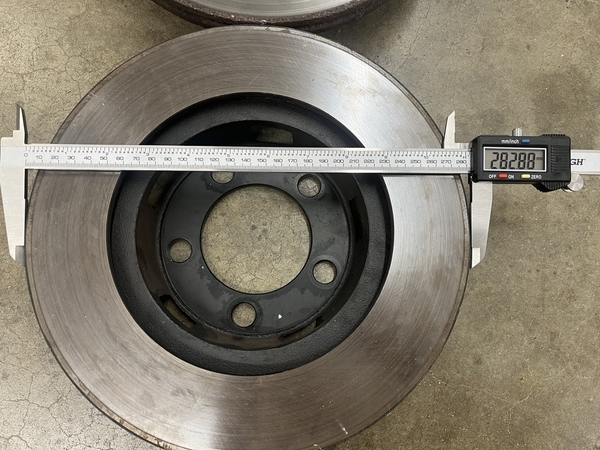

my brake discs are already turns down to 19mm - which is minimum thickness for the rotors! I am sure this was not done because of wear but because of rust! If you look at the rust scaring on the rest to the rotor and being original ( even small DeTomaso logo cast) and 50 years old and a bit over 30k miles . And at some point the disc seems to got clamped into a vice leaving clamp marks on the brake surface and 2 sharp “cuts” on the outside corner above! Also the axle nut were destroyed when they where beaten into the grove of the axle stub for safety. Things I have to address before I move on with the project. I am very surprised that no vendor has original brake discs made for the Pantera….

The new brake pads run at the very edge of the original rotors.. Doing some major cleanup and press the studs out…

Do anyone have source and part# for the wheel bearings NOT China made! SKF or so?

Attachments

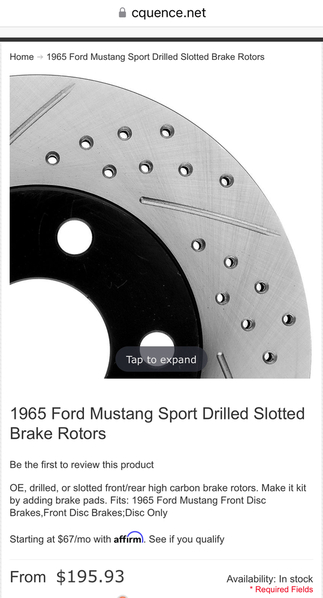

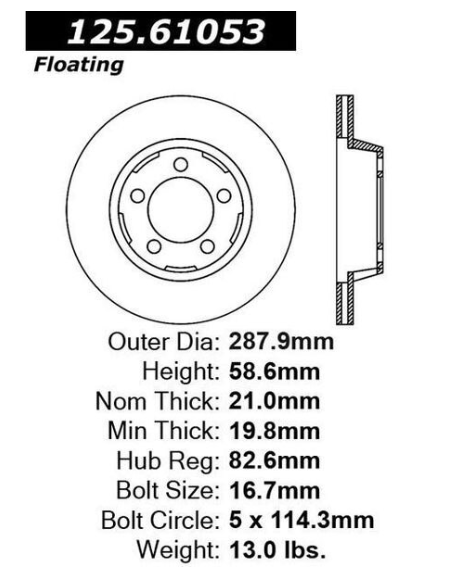

If you need to replace your rotors heres a great option and direct swap with the OEM rotor, but its got some upgrades. Mike Drew got with the people at Centric/Stop Tech and got them to make these for the Pantera Community. For many years owners were trying to find Mustang rotors that allowed the wheel bearing hub to fit on a replacement rotor, some found ones that had the bearing mount directly cast into the rotor while others got items that did not work, it was a nightmare. These solved all the problems and were improvements over the stock OEM design.

StopTech 125.61053 Premium High-Carbon Brake Rotor

They are also vented and should work great for what you are doing if your rotors need replacing.

Here's the Amazon listing for these rotors:

https://www.amazon.com/gp/prod...PDKIKX0DER&psc=1

Attachments

tomsealbeach

Just confirming that those rotors work for front and back on our cars? Looks like a good deal. As anyone used them?

No they do not work on the rear, rears are larger, but definitely on the front. I have them and as I mentioned Mike Drew (do you know of Mike?) worked with Centric/Stop Tech to build these for our cars because so many owners could not find replacement rotors. Mike has them his GF's car and also Chuck Engles has them. There are a fair number of other owners, I just can't name them. There is discussion back in 2017-2019 on the detomasolist about these rotors. Here's a snippet from that discussion: "Centric offers a dizzying array of options, starting with a plain, standard OEM-style Mustang rotor, all the way to a cross-drilled, slotted, cryogenically treated rotor (slotting makes them handed, with different part number for left and right)".

I spent a bunch of time trying to find the slotted, and cross drilled versions and was unsuccessful. When I bought these rotors I paid about $50 a piece. I spoke directly with the support people at Centric/StopTech and they could not direct me to the cross drilled or slotted versions, so I just got the standard surface, but they are vented and a fair improvement over the OEM solid rotors. The part number I posted above is the only one I could find.

Here is a picture of the slotted vented rotor that Mike put on his girlfriends car.

Great…. I give it a shot!

I ordered (that’s the beauty with Amazon, if it doesn’t fit, just return it)

StopTech 125.61053 Premium High-Carbon Brake Rotors

I’m just asking myself why on their websites they do not list any products for the Pantera…. And on Amazon, there are no dimensions …

just spoke to customer support and they don’t know anything about it.

The part number / rotor is generic for Ford mustang, falcon, comet, and such

I keep my fingers crossed. Maybe I got lucky!

Found these dimensions. There are other places that offer these for sale that do show the dimensions.

Attachments

Well, we find out soon… supposedly arriving on the 17th…

Till then I go for the rear brakes

(I wonder what surprise is waiting for me)

I do not believe that these are the exact rotors that Mike Drew ordered. I used these on the front of my car and found that the OD was too large. I had to machine them down to fit the stock calipers. Once I machined them down, I sent them out to be rebalanced since the balancing is done by removing material on the outer diameter of the rotor. That said they probably will work on the rear and may or may not clear the WilWood calipers on the front. One thing to note is that the holes for the wheel studs are not sized for our metric studs. The holes need to be bored out a little to fit, ~17mm as I remember.

…..and the plot is thickening….

Maybe I missed this at the beginning but the SAAC system was designed to be used with stock rotors? Or are there modifications to make them work?

I bought some from Rockauto, it's Centric reference 125.61053 and designated for "1966 FORD MUSTANG 3.3L 200cid L6". They mount in place of OEM discs without any modification. I paid $34.60 per unit for them in 2019.

Attachments

Yes the Sacc calipers in this tread is designed for stock rotors, but the six piston calipers can be adapted to larger rotors by repositioning the caliper with a slightly different adapter. These calipers should have no problem working on the rotor I posted above, its just redesigned slightly with venting, and much better metal than our stock rotors.

Rene Rock Auto still has them. $49

Thats a great deal.

Tsolo, below is the email I got from Mike Drew. Not sure what else to say.

Note that this is a direct bolt-on replacement for the stock solid front rotor, using the stock Pantera hub and studs. It is microscopically larger in diameter and has nominally the same rotor thickness but the offset is different by a few thousandths of an inch. However, the stock Pantera design features a goof which required them to correct the mistake with a shim between caliper and spindle to center the caliper over the stock disc. By happy coincidence the change in offset is exactly rectified by simply leaving the bandaid shim out.

I believe the part number to order the disc above would be 125-61053CSR and 125-61053CSL for right and left sides, respectively. They might have to be custom-ordered with the slotting as I had to do, but the plain non-cryo non-slotted rotor is readily available with the basic 125-61053 number.

As for pressing the studs in? You didn’t have to pay to have them pressed in. Just assemble the studs, rotor and hub assembly as much as you can, then get open metric nuts of the appropriate size, and some washers. Install the washers and torque the nuts to 80 ft/lbs. This will draw the studs in until they fully seat.

You could also accomplish this simply by bolting on a wheel and torquing the lug nuts.

Mike

These are the rotors I purchased.

@marlinjack the $2400 got me four 6 piston calipers (different bore front/rear) and separate parking brake calipers! The brake master is 1” or a bit more (1/16 or 1/8). The original front brakes supposedly are not bad but got dialed down because of the inadequate rear brakes…. So with the proportioning valve now in the rear circuit I think the brakes should work quite well. I’m not putting the car on the track, I’m just a “spirited” driver and would just hate to run out of brakes while knowing the issues beforehand. Also a better parking brake would be nice and if the front discs I just ordered are workable-GREAT! I wanted to keep the original rims because I love the look! The car reminds me so much of the Maserati Bora I drove for a while

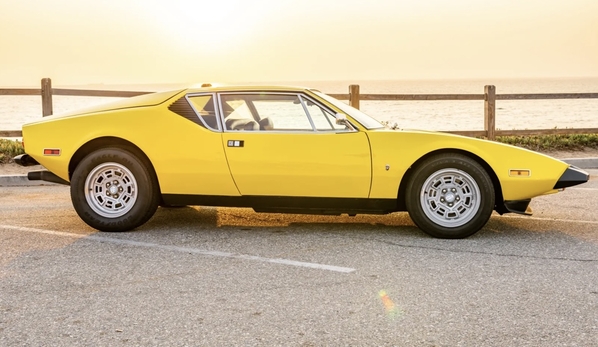

I bought this car #4679 just a few months ago and drove it for one mile and put it in the garage and start getting over the car… 30k miles in 50 years is just bad (80 miles in the last 8 years) for everything!

electric switches, electric motors, engine, transmission, gas tank, cooling system…absolutely everything… And I go through everything! And more… like moving the gas filler to the outside…..

not trying to do a restoration. I try to get all done say by end of February and I’m one happy camper !

Here are some pictures to prove my point. Take it for what you will. LeMans850i can confirm when he receives his rotors.

Note the manufacturers dimensions above

Here is the stock front rotor from my ‘74. Here is the 125-61053 after I turned the OD down.

Here is the 125-61053 after I turned the OD down.

Here is the stock rotor hub diameter.

Here is the hub diameter of the 125.61053. Note it is oversized compared to the original. The rotors will be stud centric.

Here I measure the stud hole on the 125-61053 after it has been machined to fit the stock wheel stud with a bore gage.

Here is the bore gage in the caliper.

Here is the factory stud shoulder measurement.

From these pictures you can see that I had to take 5mm off of the OD of the rotor. Without this the rotor dragged on the under side of the caliper. And, the factory stud will not register into the rotor unless the stud holes are opened up to 17mm.

Another issue is the thickness of the rotor flange. The stock flange is 9.2mm while the 125-61053 flange measures 7.75mm. The factory studs require a 1.5mm washer under them so that they do not protrude too far through the axle flange. If they do you could have an issue tightening your wheels because your lug nuts could run out of thread and bottom out.

I put a lot of time into this. If you don’t believe me, by all means feel free to try this yourself.

Steve

Attachments

@tsolo thank you very very much for your presentation!! I am looking forward to the discs and hopefully make them work and show the way and the results! You just contributed a major part to that!

Steve I totally see what you are saying. When did you purchase yours? I'm wondering if the original machining dimensions changed? That's bizarre.

Lemans 850i sorry if you have the same issues as Steve, my intent was not to open a can of worms and for you to go down a rat hole! Definitely let us know what you get. I will definitely delete my posts if these turn into a big PIA. Steve thanks for your input!

I believe that the manufacturer modified the final machining of the Mustang blank to meet the original Pantera specs for Mike when he placed his bulk order. These rotors can be made to work but require some machining and if you do it correctly, they should be rebalanced. But….. they work. I called every machine shop in town and only found 1 that could or would do the balancing.

Steve

Hey guys…. You all are very appreciated!

no need to apologize! I was googling and reading here for many hours but I could not find any conclusion for the problem at hand..

im hoping to finish this thread with definite information so the next guy has some guidance how to tackle the problem!

And all of you are important to get there..

I work on the car in my garage by myself and I don’t have a lifetime to figure it out..

just started another thread about the external fuel filler I’m building for it… you know, when I have a spare minute between brakes, electrical, fuel system, steering and and and..I’ll post threads once I got parts and ideas.. lol

im steamrolling through this project and you guys are a BIG help providing resources and information which would take days for me to find!

AND a big big THANK YOU to PI Motorsports… Jerry…can’t say enough good things about him!

Attachments

@tsolo posted:I believe that the manufacturer modified the final machining of the Mustang blank to meet the original Pantera specs for Mike when he placed his bulk order. These rotors can be made to work but require some machining and if you do it correctly, they should be rebalanced. But….. they work. I called every machine shop in town and only found 1 that could or would do the balancing.

Steve

What sucks is they are suppose to be "bolt on" and done! Wouldn't that be nice! Steve you are the first one that brought up having to machine these. Anything can be made to work with some fenagleing and jury rigging. ![]() But I guess we all know we're working with a 50 year old car, so some of this is expected. Thanks for your input here. I will certainly temper my enthusiasm on these rotors in the future.

But I guess we all know we're working with a 50 year old car, so some of this is expected. Thanks for your input here. I will certainly temper my enthusiasm on these rotors in the future.

When caliper to wheel clearance is minimal, make sure that there is enough clearance for adhesive wheel weights (if you use them) to clear the calipers.

John

Clearance is between 3/8 and 1/2”

Does anybody know what the original thickness of a new Pantera front rotor was? 21mm?

@LeMans850i posted:I am very surprised that no vendor has original brake discs made for the Pantera….

FWIW, Pantera Performance Center in Carson City, Nevada sells bolt on direct-replacement rotors.

Larry starts with a Porsche Brembo rotor and machines it to the exact dimensions for our Panteras. That makes vented, slotted, cross-drilled rotors available to us.

Not to be ungrateful for your help, but the casting says clearly the minimum thickness is 19mm!

If you convert inches to mm it gets you to 17 mm after refinishing it…

the curvature that goes from the disc to the hat is exactly flush with the disc at 19 mm thickness… I do not think you actually would machine it creating a sharp corner / stress riser in that area! 17mm is definitely not correct!

regarding the original thickness of a new brake disc I thought it may be 20 or 21 mm?!

I did see the machined Porsche rotors to fit the Pantera but the price was not anything I am willing to spend… Over $800 per disc?! if I remember correctly…

Attachments

My Centric/Stop Tech rotor is 20.98mm or .825" thick. The minimum thickness stamped on the rotor is 19.81 mm

Thank you

that makes sense!!

@LeMans850i posted:I did see the machined Porsche rotors to fit the Pantera but the price was not anything I am willing to spend… Over $800 per disc?! if I remember correctly…

Actually, PPC's vented & cross-drilled brake rotors (front & rear) are $350 ea. (I just checked the price 10 minutes ago).

Admittedly not cheap, but also not unobtanium. And it's a quality part!

now I can’t find them if my life depends on it …

could you please post the link…

edit: just called PPC… you are absolutely correct…

thank you!!!

p.s. still cannot find it on the website

Good news .. bad news….

here is the good news:

the discs arrived!!!!

bad news… the picture shows and I did call the company as well to verify it is only the disk - not the whole hub disk assembly!

….return to sender,

I was looking at it and thought maybe Machine the center out to have the right bore size 81.9mm and then Machine the thickness of the flange down to have the 9.2mm flange thickness… But the additional 1.5 mm are on the wrong side not centering the disk in the caliper so that’s not gonna work either. It would be just a cluster f@$&..

I think I’m gonna put the mustang to rest!

I don’t think Mustang is the solution…

(some may say “he gave up too early”, but I was reading a lot about that subject, and there were many many failures, and only not even a handful of success stories) . Just a few were successful with major effort and help from the manufacture of the disks… Not easily repeatable!

I’m going to order the disks from PPC... 350 dollars apiece 700 dollars for the axle … I want to see what I get ! one thing I really would like to see is the inside diameter if it has the proper fit going over the hub and center the disk! I think there’s a lot to ask from the studs, but not centering the disc permanently on the hub with the protruding cast for the bearings… The disc is not gonna just rotate, but when you apply the brakes, it tries to pull away from the center as well. Maybe I’m overthinking… Again…

Maybe I’m overthinking… Again…

I’m gonna see if I can come up with something better and more sensible but to get the Banana running Porsche discs it is!

I am bummed

Attachments

In a correctly dimensioned bolted assembly, when tightened to the correct torque, the studs do not work in shear but only in traction and the forces are transmitted from the rim to the hubs only by adhesion.

It is nevertheless preferable to separate the centering and fixing functions, but it is not essential.

Can’t quite tell since it is in the bag, but what you received is a one piece casting incorporating the hub and the rotor, correct??

Honestly, this is what I expected you to receive. The effort Mike Drew put in to have Centric provide just the rotors was a one time thing. Perhaps it can be done again?

I am running Mustang rotors at all four corners with Willwood four piston super lite II calipers. Functional but with some drawbacks due to diameter. I sourced them off of eBay sellers

originally the rotor and the hub were separate pieces and you can still find old stock rotors. It became cheaper and more efficient to machine hub and rotor from a single casting. I believe almost all the raw castings are made at two or three China factories,

Larry

Rene your Rotors came with the hub, bearings and the wheel studs! Thats surprising. I have the same part number and the rotor came bare!

@tomsealbeach posted:Rene your Rotors came with the hub, bearings and the wheel studs! Thats surprising. I have the same part number and the rotor came bare!

Tom, I am betting you got those rotors many years ago when they were still being supplied as separate rotors. Or you got them during the Mike Drew special order program.

Yes?

Larry

I purchased mine 2-3 years ago after calling Centric to confirm that they were discs only, no integral hub. I believe I ordered mine from Summit Racing. Maybe call Centric like I did or call Summit Racing and see if you can get someone to go open a box.

Steve

I just searched eBay for separate rotors. If you study the listings, some of them will mention it is a hub and rotor combination. But many depict a separate rotor with no details in the auction

I sent messages to four sellers asking if they could confirm that the photo of a single rotor matches what they will supply and they have all replied they have all the information available listed in the auction.

Doubtful if any of them are separate rotors.

Larry

Here's a nice hub if you are going in deep. Just FYIing it to you

Here's a set of original rotors.

I purchased a set of those Porsche discs from Larry before going this route. The Porsche discs are an aluminum hat that he has machined to fit the Pantera hub, bolted to the cast rotor with maybe 6 5/16" bolts if I remember correctly. The set I received were machined so bad that they were not useable. I sent them back to him and explained the situation. He wanted to send me another set, but I've been disappointed enough by vendors to have learned my lesson. Then I called Centric and went the Mustang way. Maybe as you said you can cut the center out and machine down to the 7.75mm thickness and use washers behind the hats. Thats what needs to be done on the Wilwood hats. That said look into a set of Wilwood hats and rotors. Scott (SACC) should be able to help with that.

Steve

Yet another interesting one.

You might also read this thread from earlier this year

I'm not surprised there was a switch. This seems to be continuous across the industry. It is a 65-67 Mustang front rotor and has been one piece with the hub for four or five years WITHOUT a part number change or even a notation. Been there, done that.

Considering that fact, personally I am in the group that says if "we" are going to screw around with making a rotor for the rear, make it vented and so it mounts over the wheel hub so it is simple to remove to have resurfaced without tearing the rear assemblies apart.

@tsolo bursting bubbles….. I would have thought the Porsche disc would be the hot ticket… price wise it’s going to be a tossup between Porsche and Mustang… machine shop time will compensate.. LOL..

do you have any pics of the Porsche setup?

@panteradoug. I think you are absolutely right… 65/66 mustang front brakes are ALL now one piece… A handful of foundries in China and the difference in price is probably the amount of carbon added ..

just nobody changed the pictures.. I called centric and she said “it’s just the disc! No hub” I guess she was just looking at the same pictures as I did !

trust me, I was sending a few e-mails about making connections to cast the discs… But it’s quite an undertaking.. and then, the next question is how many should be made…? And some liability question is coming up as well…

Hmmmmmmmmmmmmm🤨

Larry they were ordered from Amazon in 2019.

One of my client was and may still be the US Supply Chain Manager for Centric. I'm going to call him tonight or tomorrow and see if there is a way to get an order of the correctly machined and dimensioned rotors. I'm a bit surprised that this is such a crazy thread, but since there are numerous threads just like this over the years maybe we can get something done here. I will report back shortly.

I don’t have a picture that shows the Porsche rotor by itself but I did find one with it mounted on my car. Of course I didn’t find the problem until I had both sides fully installed and tried to spin the hubs. The problem was runout. The machining on the hats was very bad which caused excessive runout. I think he sources these from somewhere and then modifies the hat. I think he reduces the height, opens up the hub diameter, and redrills the stud holes, from what I could tell and remember from looking at them. I was also concerned about the limited number of bolts holding the hat to the rotor.

The problem was runout. The machining on the hats was very bad which caused excessive runout. I think he sources these from somewhere and then modifies the hat. I think he reduces the height, opens up the hub diameter, and redrills the stud holes, from what I could tell and remember from looking at them. I was also concerned about the limited number of bolts holding the hat to the rotor.

This is just my personal experience.

Steve

Attachments

@tomsealbeach that would be fantastic…

this brake disc issue is around for a long time…. And 99% of the time it seems like it just fizzled out … in defeat.

@tsolo yes… that does sound funky, and it would concern me, too!!!

and there goes another Hmmmmmmmm

@LeMans850i posted:@tomsealbeach that would be fantastic…

this brake disc issue is around for a long time…. And 99% of the time it seems like it just fizzled out … in defeat.

Here's what I think the problem is, the Pantera numbers are already small, but at any one time there might be 10-20 owners that need replacement rotors. A company like Centric is owned by another parent company called APC Automotive Technologies, I recall StopTech was another company under that umbrella. APC filed bankruptcy in mid 2020 (maybe because of pandemic related issues but that was just the start of the pandemic). Taking on a specialty project for a production run of 50 or 100 rotors at a $50-100 retail price isn't a big project to these companies and thats why we are seeing these problems. Although, a production run might make sense if this part is an identical part match and cross fit to a Mustang rotor for 68-69 cars. Does anyone know which cars rotors are an identical match? Mustang, Cougar, Maverick etc? I'm just thinking forward on the arguments Mike Drew had to deal with when he made the deal with Centric to do a limited run.

After a long hot bath, here is what I come up with:

the 66 Mustang rotor/hub combination I just got, use it as the base…

1- machine the center to 81.9mm

2- machine the mounting flange to 9.2mm thickness which should make the disc 60.1mm high ( remove from wheel side)

3- machine disc to 282mm OD

4- machine bolt holes to 16.95

5- balance

6- water jet shim to offset caliper additional 1.5mm (my car had two shims on each side to bring the caliper to car center) because the disc is 1.5 mm per side further in I think we can live with that

I do not know if the flat spot on the head of the stud has something to bite on so it cannot turn. If there is nothing there could be a small recessed machined on the inside - one millimeter would do. if that’s the case… Have to go through the numbers again! Height increases to 61.1mm and caliper shim to 2.5mm

this way, we have full flange thickness, we have the proper diameter hole to center the disk on the hub, no washes needed under the studs…

If we can find a machine shop that could make the prototype and then maybe make a run of 50 .. or more??! It should become quite efficient doing same step on all and then switch for the next step on all and so on…

was my bath too hot 🥵???

Wow. What an amazing amount of machining and money just to adapt thin vented rotors.

some Willwood calipers can be widened with a spacer, which would allow the use of the thicker vented rotors used on the later mustangs.

cooling improves with venting, and also improves the thicker the rotor.

My point being, if you’re going to go to all this trouble, why not do it with a thicker and better rotor?

Or, if you choose, or have to stay with the thin rotor for your calipers, you can make this considerably simpler by just buying two of the separate rotors in the screen capture I posted earlier in this thread….. however they are also also thin, and thus not the ideal choice

Larry

I properly could go a couple mm thicker on the rotor but it would be a good fix just for me.. I was looking if there is a possibility to get a solution for everyone with original brakes (and wheels)! I’m not racing the car… just some spirited driving…

the work to the 66 discs reads like it’s a lot but it really isn’t..

once you did the prototype it would be pretty fast…

deck the flange (to the wheel) to the correct total height

machine center hole

OD of disc

5 hole (other thread says they already fit to press studs in)

balance (not sure about that… didn’t see any balance marks on new discs)

@lf-tp2511 posted:Wow. What an amazing amount of machining and money just to adapt thin vented rotors.

some Willwood calipers can be widened with a spacer, which would allow the use of the thicker vented rotors used on the later mustangs.

cooling improves with venting, and also improves the thicker the rotor.

My point being, if you’re going to go to all this trouble, why not do it with a thicker and better rotor?

Or, if you choose, or have to stay with the thin rotor for your calipers, you can make this considerably simpler by just buying two of the separate rotors in the screen capture I posted earlier in this thread….. however they are also also thin, and thus not the ideal choice

Larry

It is a lot to go through for sure! After seeing your response above I went back into a a few emails I had with the company that is the customer support to Centric and StopTech. At the time a manager was really helpful and gave me an email with this comment in it:

"Preemptively speaking we seem to be able to produce the slotted rotors. This would require an order of 6 sets of rotors (total of 12 altogether). I do not have a cost yet, I am trying to figure that out now."

When he said 12 rotors I said I'll just go with the non-slotted rotor because I didn't need 12. But he also mentioned that he can also make rotors that are not "static part numbers"! This must be how Mike Drew got his original batch made.

I have this guys phone number and some past correspondence with him. He was great so I will reach out to him on Monday on regular business house and see if we can get different dimensions made.

Well, that would be the ticket!!

Once there is a price on it let’s get an idea how many should be made…

send him an original rotor and make it 21mm thick and vented.. right!!

anyone who is interested PLEASE pipe up on this thread!

@tomsealbeach posted:Rene your Rotors came with the hub, bearings and the wheel studs! Thats surprising. I have the same part number and the rotor came bare!

I received the rotors alone, without the hub but it was in 2019.

@LeMans850i posted:Well, that would be the ticket!!

Once there is a price on it let’s get an idea how many should be made…

send him an original rotor and make it 21mm thick and vented.. right!!

anyone who is interested PLEASE pipe up on this thread!

That's a great idea to send an original rotor! Definitely will do that. Hmmm, maybe I'll do the rear at the same time.

Yes, rear as well!!! Same design or outside mounted? I am not sure if that is possible… I have to have a look, take a wheel off …

they are raising some issues… Wheel studs getting too short …

, sticking with the original design but vented is probably best and most doable!

There is a "core" existing that could be used for a rear rotor.

If you look at a GM '98 Blazer rear rotor, that would be the core.

Now I call it a core simply because it isn't a simple bolt on. It is the thicker rotor, i.e., .970" and it is 12.3"od. It uses a GM bolt pattern, not the Ford 4-1/2" center. It is vented. The center hole will clear the Pantera's center hub.

What is significant though, is that it has the necessary interior clearance to clear the o.d. of the Pantera rear hub, and the necessary set back to mount externally.

The bolt pattern can be redrilled to the Pantera pattern and the od can be turned down to what you need but the rotor thickness is probably going to be the main issue to deal with if you want to keep your calipers?

So any machining necessary would be done on the rotor and not on the Pantera.

Because it has the necessary depth to sit over the Pantera's flange it has the ability to be shimmed to center it in combination of shimming the location of the calipers.

I am still looking for that rotor in the thinner .847" thickness but it does not appear that there is one that exists but it is a start and for those of you that are sourcing hunters, it could be the beginning of a discussion with a brake rotor company.

I just haven't found a cross reference of rotor sizes yet that I can search an application for. Most cross references are for "original applications" and don't list the critical dimensions of the parts. That's the cross references that I need to find the thing, if it already exists, which is probably a 50/50 thing?

Being a common GM application helps with availability and pricing.

What I did on my brakes was already posted so I won't bore you all with repeating that but I would like to find a rotor that installs over the Pantera's rear flange, so that's why I keep looking. "You never know" and you won't find it if you stop looking? There is no doubt that something will need to be done with the rear studs but that is likely a minor change.

When converting to outside mounted brake rotors, a solution to the longer stud requirement, is to use 1/2”-20 studs. They are available in any length you want, inexpensive and much stronger than the OEM studs. Dennis Quella even has DeTomaso logo lug nuts with a 1/2”-20 thread.

Originally the discs are held on with the same stud, correct? I haven’t taken mine apart, but if we lose the disc in the back, the stud protrudes more in the front therefore, the original stud should work ….

I’m just throwing it out there… Wilwood makes so many hats and discs… I’m quite sure there is some configuration that works… I stumbled across this.. not drilled!!!!!… and it says order your size!!

Attachments

Looks like they have drilled versions also so for what you have with the Wilwood calipers you could remake a bracket that would mount the caliper pretty much where you need it. Your calipers may also take a thicker rotor for better heat disipation.

The outside diameter of the rear axle flange on mine is 6.065".

I looked through available hats and saw most limited to a 5.750 od flange. You also need to get close on the depth of the hat as well.

With all the offsets with seperate hats and rotors, you need to get in the ball park in order to mount the calipers closely enough and preferably in order to shim them .

This is all doable but going in blindly is going to wind up with a lot of non-returnable extra parts.

Also, In this case it probably doesn't matter a lot but the GM rotors are $45 each but the commoness of a rotor for future replacement purposes would be preferred.

A friend gave me the name of a rotor company that will make anything for you. This guy restores classic race cars and this company is really the source of NASCAR components like brakes.

That is all well and good if you have a budget of $300 to $400 per rotor?

I believe that the front DT studs will work in the back when swapping the rotors to the outside but there are metric studs available in different configurations for race cars. The studs should not be the determining factors.

@LeMans850i posted:Originally the discs are held on with the same stud, correct? I haven’t taken mine apart, but if we lose the disc in the back, the stud protrudes more in the front therefore, the original stud should work ….

Not exactly. When moving the rotor to the outside, if you keep the stock studs or stock style studs, you need to put a spacer the width of the original rotor hat, between the head of the stud and the stub axle, so that the splines on the stud still sit in the axle in the same position as they did before. That results in a stud that’s effectively shorter by the width of the new rotor hat. Even when putting two piece Wilwood rotors in the OEM location, you need to shim the wheel studs by an amount equal to the difference between the thickness of a stock rotor hat and the Wilwood rotor hat. I wonder how many people install a Wilwood brake kit and wonder about the washers that are left over after the installation!

True both of you…. Early in the morning not enough coffee,😵💫

Finally getting back on to the brakes!

I’m still trying to get some new discs made, but at this point my lovely wife would kill me if the car sits another six month just like that in the garage! So I got a set of used discs..

the bigger hold up were the highly unusual polyurethane bushings… Did a little write up about them here on this forum… Look for “

weirdest Poly bushings ??!!

” if interested..

Now that this problem is finally sorted in the rear I am back on to installing brake calipers…

one thing I forgot to do when I had everything apart was to chase the threats on the forward part of the uprights! Now I have to do it already installed in the car which is not very fun! Just test fitted the left side….

Also I got a new parking brake cable because on my original one the plastic shielding around was 80% gone and water got inside and it rusted itself in place…

Attachments

(working on the front bushings)

Finally I could go back on the rear brakes..

the way the parking break calipers set up the brake cable is routing straight forward from the caliper, then follows the lower arm front under the headers crosses (I added 12” of heat sleeves per side) to frame, and then makes the turn towards the pulley,. This is a considerable shorter distance than the original route! So after test fitting it I marked the amount each side has to be shortened and the combined amount, the cable has to be shorter. I found a company in SoCal that can do that and I drive there on Tuesdays.

i hate if I have to do extra loops/turns… just not an option!

Attachments

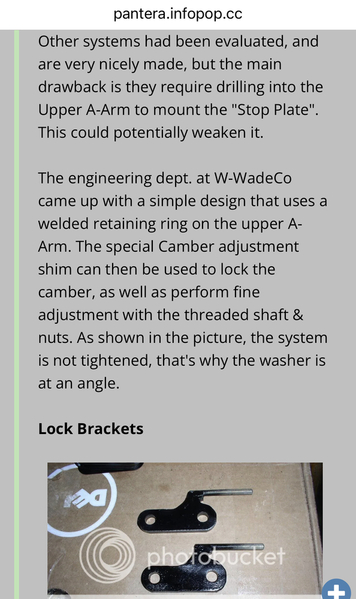

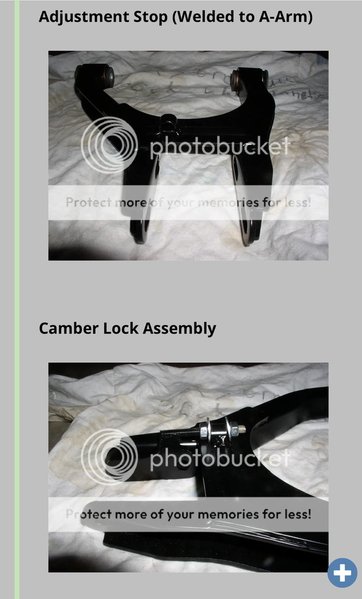

Are you looking at camber lock options?

(or is that another thread?)

Here’s how we (mostly Wade) did it… the discussion is on Page 4… scroll down.

Attachments

@rocky posted:Are you looking at camber lock options?

(or is that another thread?)

Here’s how we (mostly Wade) did it… the discussion is on Page 4… scroll down.

I just read your thread… You pretty much did everything! Which is about where I’m going in the end… double thumbs up to you,👍👍

I think I’m gonna skip the camber lock… I talked to Jerry at PIM About it, and he essentially said if I’m not going to do heavy duty racing it’s pretty much a mute point and if I bump anything it just moves to ball joints versus bending some more structural parts… if it does create a problem, I will address it!

i’m gonna focus right now on the Wilwood break conversion and hopefully getting my parking brake cable shortened and get the wheels back on. They haven’t been on since they got redone! Can’t wait to see that!

and then still lots of electric, fuel system,(Holley is already done) external fuel filler and on and on..

well, YOU know how that works 🤔😁

Attachments

The biggest problem with my (I bought it about 4 months ago and drove it 1 -one- mile) Pantera is that it was in a museum starting 2016 and then got sold 2021 and was sitting in a garage. There was work done to the car pre 2016 seems like including a repaint (car was taken apart) and I guess the poly bushings, half shafts and other little things but when they put it back together they assembled it dry… no grease anywhere!

door hinges, window mechanism, head light mechanism, locks, and then also (age related) speedo cable, pedal box, wiper assembly and so on!

Now I am sure that a lot has to do with being 50 years old and it just dried up and maintenance was “deferred “ LOL

I found proof that between 2016 and the time I bought it in 2022 the car got driven for 80 (eighty) miles !!

Someone took -keeping it -ORIGINAL- way to serious!🧐 I am sure that the gas I drained out of the fuel tank was 10 years old… -Maple syrup- and Coca-Cola brake fluid together with all leaking seals, and rusted brake discs… (omg to the rear wheel bearings)

I have my work cut out with it, but I’m making my own and no, it will be not original! Period correct YES but not another “original “ Yellow L Pantera! There are enough of them out there..

Another fun fact… when I get in the car the seat is expelling yellow foam powder…

things to do….

UPDATE FROM THE PRESIDENT OF CENTRIC ON THE ROTOR PART NUMBER 125.61053

My client who was Ops Director for Centric (but at a different company now) reached out to the current President of Centric on our dimension problems with their rotors and was told that "we no longer catelog those parts and neither does their other division (presumably StopTech). The part number/SKU has been killed off, otherwise the obsolete inventory problems never get resolved".

Centrics parent company went bankrupt a few years ago, Centric was spun off to a new parent company. We asked would they consider doing a limited run with specific dimensions again for Panteras and were told NO!!! Per the President "New ownership new strategy". The president actually went online trying to help out and refered me to PI Motorsports website sending a picture of the parts PIM has on their site.

Back to square one and this seemingly never ending rat hole!

Sorry, I tried.

Wow… that sucks big time!

I really really appreciate your help… I will stay on it and now that I have the original front and discs of my car, therefore have samples I will contact casting outfits!

The biggest question I have is how many should be ordered..???

Attachments

Big shout out to “control cables Inc.” in Santa Fe Springs, California.

They did an absolutely perfect job!! Precisely shortened the amount I asked them to - the outside shield and the inside cable.! It’s a perfect fit!!!! $30 perfect 👍

added protective fire sleeves around the parking brake cable on both sides to protect from chafing and from the heat from the exhaust headers.

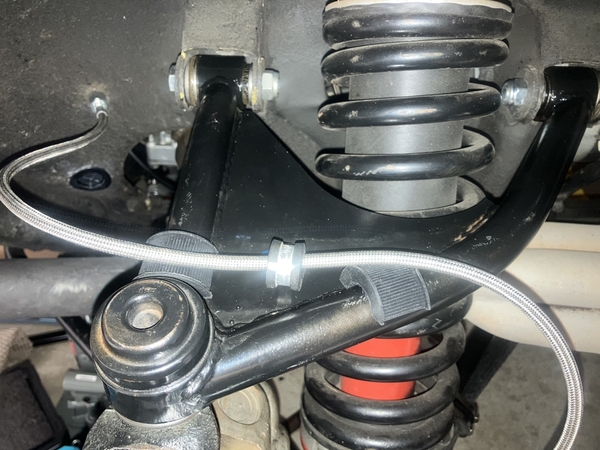

Secured the parking brake cable to the A-arm with stainless steel zip ties (protected the arm first with electric tape then a rubber grommet, then the zip ties )

clearance to the half shaft is well over 1/2” and the cable is absolutely secure!

for securing the hydraulic line I drilled and taped a M5 hole in the webbing of the A-arm and used a clamp that allows movement….

Attachments

Nice job Roland. Thanks for sharing your experience with your vendor "Control Cables, Inc.". Need to spread the word regarding great vendors. Larry

Nicely done. That reminds me that I need to go back and clean my cable management up after doing a similar brake upgrade.

finally, I got the heat shields for the front brake back from Powder coating!

original pretty rusted but now all good again!

Now I’m moving again

new seals

Attachments

Here a look at the different size pistons front caliper

not sure if I mentioned before but I always chase the threads ( lubed and turn - turn and back off - and again..) and clean the threads afterwards with brake cleaner so the blue Loctite has a chance!

Attachments

Front calibers are mounted (108 foot pounds of torque in the confined area is scary. Anything slips your faces is toast)

brake lines installed, master is filled

Attachments

Roland, Looking Good, At this rate you will have it on the road in no time. Larry

And I got brake pressure and no leak!

the pedal is getting hard is about 1 3/4 maybe 2 inches rock solid..

i’m sure I got some air trapped somewhere… Being one man show so…

I’ll give it another go tomorrow.

but all in all , I’m very very happy not bad at all!

Oh… did I mention that the parking brake actually is holding the car! I can torque the wheels with the wheel in the air, and it does not move at all!

@Lardog posted:Roland, Looking Good, At this rate you will have it on the road in no time. Larry

You are right… If I wouldn’t do aaaaaall the other things… 🤪

just doing every day a little bit - and don’t get complacent..

Well, it’s done… I hope they brake as good as they look… new system from foot to road…

new Pantera brake discs are not off the table but it takes time… working on it!

thanks to everyone!! 🙏

now I’m moving on to the external fuel filler…. https://pantera.infopop.cc/top...rnal-fuel-filler-mod

One last thing… does anyone have an intact screw on cap for the original clutch or brake master reservoir.. they seem to be the same…. With the rubber inside..

I need one… DM me… PayPal…

hope this thread was helpful… ✌️

I’m curious to hear how the six piston calipers feel on stock diameter rotors, in normal driving. Please let us know!

I sure will give a total test report on the brakes after she is technically done… hoping in April…

thinking about it… I will actually let an experienced Pantera owner/driver from this forum run my car and report.. I don’t have any seat-time in the car… what do I know!!

Lemans850, those screw-on plastic master cylinder caps always crack from tension at the first thread unless you leave them loose... and then they leak. The caps can sometimes be found in wrecking yards on old Volvos, FIATS, some Brit cars but they're always suspect after all this time.

If you want to fix the cracking forever, go to <pegasusautoracing.com> in WI) and get their ALUMINUM cap (pn 3549). Fits perfectly and could be painted black if the as-cast look is a problem. I put mine on 30 yrs ago & so far zero problems.

@bosswrench posted:Lemans850, those screw-on plastic master cylinder caps always crack from tension at the first thread unless you leave them loose... and then they leak. The caps can sometimes be found in wrecking yards on old Volvos, FIATS, some Brit cars but they're always suspect after all this time.

If you want to fix the cracking forever, go to <pegasusautoracing.com> in WI) and get their ALUMINUM cap (pn 3549). Fits perfectly and could be painted black if the as-cast look is a problem. I put mine on 30 yrs ago & so far zero problems.

Thank you bosswrench! Super information!

you would not believe how much this flimsiness was bugging me!

I just ordered 2 of them!

👍👍🙏

Attachments

Attachments

I don’t know if it was posted anywhere already… the nut for the front wheel spindles are from Fiat 500 – Fiat 850 Still available! The nut with the groove in the corners of the hexagon is left-hand side the one without right hand side!

Attachments

I am still working on getting new original size Detomaso Pantera brake discs for front and rear made!

does anyone know the original thickness of the brake discs? The minimum brake disc thickness is cast into the original ones, but I have no reference anywhere what the original thickness was! Front minimum 19 mm rear minimum 17.5 mm.

Most U.S literature refers to '0.875' (std) and 1.25" (Gr-5 & racing) thickness rotors even though the real dimensions are likely metric. I don't think its very critical- enough to finger-fit a brake pad in place.

@LeMans850i posted:I am still working on getting new original size Detomaso Pantera break discs for front and rear made!

does anyone know the original thickness of the brake discs? The minimum break disc thickness is cast into the original ones, but I have no reference anywhere what the original thickness was! Front minimum 19 mm rear minimum 17.5 mm.

It's likely your Wilwood calipers were designed to be used on a specific rotor width, that's different than the OEM rotors. In fact, probably wider. Look at the part numbers on the boxes and look it up on the Wilwood web site. That info will give you a few more options when looking for rotors. SACC might even have two piece rotors in close-to-OEM dimensions.

That would translate to 22 mm for the front disc… 19mm being minimum then I would go for 20 mm in the back..

I cannot find anybody who can reproduce the brake discs for a reasonable amount without making 10,000 of them…

i’m going to try another way… and unless somebody found already a substitute that fits the 15 inch wheels

On my all-Wilwood braking system (front and back), I used Porsche 911 (early version with 15" wheels). They fit stock AND Wilwood calipers, but need a thick aluminum spacer/adapter to bolt on. The rear discs also need lathe machining to fit the Pantera uprights and axle flanges. The ODs match the Pantera discs, too. Larry Stock at PanteraParts.com sells these.

@LeMans850i posted:I cannot find anybody who can reproduce the brake discs for a reasonable amount without making 10,000 of them…

i’m going to try another way… and unless somebody found already a substitute that fits the 15 inch wheels

You need to go into the current race car circuit. There you will find existing companies that will make any rotor for you.

How much do they cost? Don't ask but they are still less expensive then you can do yourself presuming that you put a value on your own labor time.

I will say that because the original Pantera rotors are solid, you really can cut them past the original posted minimums. That is for most street use and if you are doing a lot of "open tracks" events, you need to go to a system that is easier and more economical to replace at the track on track day.

The rotors themselves generally are ok to over cut but at some point there is a safety factor for limiting the amount of travel that the caliper pistons should be used to. That is affected by the thickness of the rotor.

The original Pantera is just a hybrid of so many parts, including the brakes and I seriously doubt there was any consideration to the car existing 50 years into the future?

I personally have seen experienced "Vintage Racers" go through two or three rotors and pads IN PRACTICE before the race even starts.

At the time that came to $100-150 per corner so it gets a bit pricey just on brakes, not even counting the tires so it isn't as simple as just driving the car to the track, running it, and then driving it home.

You need a plan first and that includes all of the above considerations.

There aren't any vendors that can sell replacement rotors to you at $30 each that don't originate in Taiwan. They are modifications of another application

Lemans, I meant to congratulate you on your front brake hose restraints- very neat. For those who don't realize, those dot-3 stainless braid hoses move around a lot during driving, and the stainless braid is quite a bit harder than magnesium wheels. One club member had his machine a groove in one wheel- which is only 0.185" section thickness. It was deep enough to cause that wheel to be scrapped. And if you go with stock rubber, the spinning wheel will wear away the rubber hose..... Tie the darn things down!

Lemans, can I trouble you for the model number of your front calipers ? They look like the Dynapro 6A s and I know they are handed. The piston diameter would be enough to determine it if you know that .

Also was there a model reference on the lug mount adaptor ?

Thankyou

At the risk of being crushed by the forums collective knowledge and opinions, of which there are many ,I did have a look at the front rotor question with respect to current Wilwood products.

The best Hat option would appear to be

The PCD , Hub center and offset appear to be spot on. The application note says this is a Pantera specific part. It is similar to the blank hat but with all the hard machining work done and all the dimensions seem to line up .I could not find the face thickness to check that dimension, but we should be grateful Wilwood are offering this product.

Remember you only have to buy the hats once !

Rotor options are available in either 0.81( 3 off) or 1.25 inches ( 2off ) .

Here are the 0.81 inch by 12.2 inch rotor options to match this hat:

Here are the 1.25 inch by 12.2 inch rotor options:

The four piston FSLI Symmetrical Caliper dimensions look like they will go on these rotor widths and still fit in a 15 inch standard rim.

The 12.2 rotors are 6.1 inch radius plus the caliper clearance gives a 6.85 outside clearance requirement without andy gap.

The inside surface of the std 15 inch rim at my best measurement 14.35 inches giving a radius of 7.18 inches. Anyone else with another measurement on the inner diameter please speak up.

This should give just enough clearance ( around 5/16") for the occasional adhesive wheel weight to go rocketing past.

You can get these to suit both rotor widths

0.81inch width with a 1.25 inch diameter pistons

1.25 inch with 1.38 inch diameter pistons

I did have a look at the six piston dynapro options :

At an outside radius of 6.97 inches on the 12.2 inch rotor you only have around 0.2 or 3/16 of an inch. Not enough for any wheel weight clearance and getting pretty close to the nelly, but a miss is a mile!

These are all straight off the shelf - no machining required.

Lemans will probably let us know down the track !

Cheers.

Attachments

Just for a fun comparison here is a four piston Dynpro caliper mounted on an oversized 12.6 inch rotor sitting inside a 15 inch rim.

Still fits but only just . Wheel weights would likely be toast and jam depending on where they were mounted.

I think the 12.2 inch rotors that match the Pantera hat as offered by Wilwood would clear just fine and would be a perfect choice dimensionally.

Attachments

@Percy I will see what I can find… I still have the original boxes, but I do not know if their part number is on it

Thanks Lemans!