Thank you for all these leads.

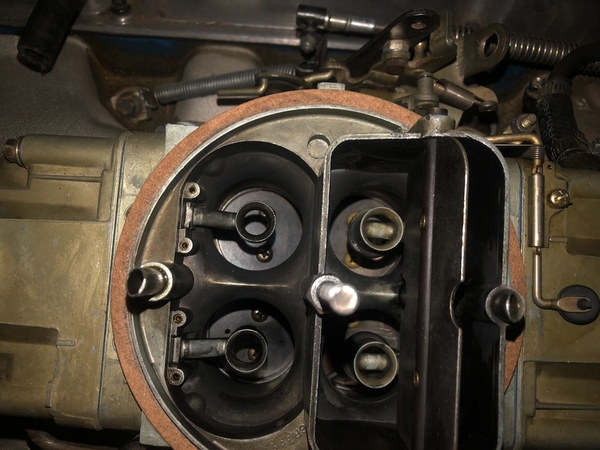

I have a BlueThunder "Pantera" manifold and so the carburetor is horizontal. There is a half inch spacer.

I set the fuel pressure to 6 PSI and checked to make sure the fuel wasn't overflowing through the level hole. As I write this I realize that I only checked one side, I'm going to check the other.

I find it hard to imagine that the carburetor is the only one responsible for the countless backfires.

I modified the advance 10 times in both directions and it doesn't change much.

I will measure the compression, if a valve is no longer tight I will detect it easily.

If everything is good, all I will have to do is try with the old carburetor.

I purchased this carburetor along with several other parts from an Australian supplier. For certain parts he clearly told me that they were Chinese equipment, not for the carburetor which he assured me was indeed a Holley. Have you heard of Chinese copies?

I have not heard of Chinese Holley copies. I have been told that there have been issues with Holley reproductions of specific "historical carburetors". I HAVE had issues with new needle and seat assemblies. Exactly where they are made is not indicated even in Holley bubble wrapped packages.

I believe the issues are with the emulsion tubes either missing, incomplete or not correctly installed. Those are under the brass plugs in the main body and not normally customer accessible. YOU should leave them alone. That is a rare occurrence but it has happened enough to notice it.

It was also said that there have been issues with the idle transfer slots on one or two that would effect the idle of the carb. My Holley specialist recommendation was not to send the carb to him for investigation but to return it to Holley under the warranty.

I personally have had the biggest issues with the Viton inlet needle and seats. Sometimes the brass floats colapsing.

The needle and seat seems to have an issue with the Ethanol in the fuel and tend to stick CLOSED after sitting for too long a period of time. What is that amount of time? It is not specific but could happen as soon as two weeks as the fuel in the bowls evaporates.

I have had issues with the old brass type floats and change those to the newer Nitrofil black plastic floats in the carbs that I use.

What will happen with a Holley if the inlet valve sticks closed or you loose fuel flow to the carb, if it is over a certain throttle opening like in WIDE OPEN THROTTLE, the engine will backfire violently. It is powerful enough to blow a hole in a cast piston and possibly even on a forged piston, break what we refer to as the upper piston ring lands, i.e., the small amount of piston just above the top ring.

So most of these Holley issues are now seen by engines that sit dormant after having been run, carbs that have sat new for too long in the box generally in a warehouse where temps run well over 100°F and floats that have not been re-adjusted at first new installation time. Also, heed the caution not to use more then 5 psi at anytime.

Rene: in the US we often see those temperatures in warehouses in the southwest US in the summer. Texas, Arizona, Nevada and even southern California desert areas. Those areas have many storage facilities because of the low tax rates. I can personally verify that temperatures within those warehouses often go to 135°F. Some of the components of items stored there under those conditions are vulnerable to heat exposure.

I've had items come out of there that have "peel off stickers or decals" installed by the factory that now are baked on because of the excessive heat. Australia has become an area where excessive heat occurs regularly as well. So just mentioning these factors in order to give a greater understanding of the variables and to point out that consumers can not assume that because an item is 100% new, it is 100% perfect. This is all part of the new world that we all live in and we all need to be educated and informed consumers now.

Probably the "best solution" with a Holley is to have a spare that is known by you to be good when you used it. That you will need to compare the carb in question to while the engine is running.

If it is dry, i.e., no fuel in it, turn it upside down and listen for the floats, both of them to drop. You WILL hear them and that is enough to ensure that the inlet valves are working. They will not need to be re-adjusted. You can leave the floats alone.

Someone mentioned Weber carbs. Usually on a V8 engine that is referring to a 48 IDA. I have quite a bit of experience with them and actually find them to be much easier and very dependable to deal with verses the Holley carbs.

The issue with them is that people attempt to apply their Holley knowledge to them and they are just a different train of engineering thought and the two trains of thought often do not match.