Any word on these blocks yet?

Ron,

Tod has not made any further public announcements, I have no additional news. You may want to write him an email at tlb427351@yahoo.com

Tod has not made any further public announcements, I have no additional news. You may want to write him an email at tlb427351@yahoo.com

I need my 'luminum!

I corresponded with Tod a couple of weeks ago when I sent my deposit in.

He estimated he was 4 to 6 weeks out on the first blocks to go to two

engine builders for testing. He subsequently made the following post:

"Anyone have a 50 taper horizontal? Minimum travels 28 cubed. Coolant

thru needed. Helical interpolation. Rigid tapping not necessary.

Preferably within driving distance of Youngstown, Ohio. I need to

have blocks machined. I need other work quoted too. Please do not

respond in this thread. Email me privately. tlb427351@yahoo.com"

So it looks like he has castings that need to be machined into finished

blocks. Tod is a man of few words. Another poster explained the above

means he is looking for a horizontal machining center and that 28 cubed

means 28 inches of travel in all 3 axes (most horizontals will have a B

axis meaning the table spins to allow 360 degree access). 50 Taper is

the size of the tooling in the spindle. 50 tooling is big heavy and very

rigid for heavy cuts and fine boring. Thru coolant means coolant is

pumped at relatively high pressure (100 psi) thru the spindle to get

directly to the cutting tool as opposed to flooding with coolant via an

external nozzle.

Dan Jones

He estimated he was 4 to 6 weeks out on the first blocks to go to two

engine builders for testing. He subsequently made the following post:

"Anyone have a 50 taper horizontal? Minimum travels 28 cubed. Coolant

thru needed. Helical interpolation. Rigid tapping not necessary.

Preferably within driving distance of Youngstown, Ohio. I need to

have blocks machined. I need other work quoted too. Please do not

respond in this thread. Email me privately. tlb427351@yahoo.com"

So it looks like he has castings that need to be machined into finished

blocks. Tod is a man of few words. Another poster explained the above

means he is looking for a horizontal machining center and that 28 cubed

means 28 inches of travel in all 3 axes (most horizontals will have a B

axis meaning the table spins to allow 360 degree access). 50 Taper is

the size of the tooling in the spindle. 50 tooling is big heavy and very

rigid for heavy cuts and fine boring. Thru coolant means coolant is

pumped at relatively high pressure (100 psi) thru the spindle to get

directly to the cutting tool as opposed to flooding with coolant via an

external nozzle.

Dan Jones

Here's another update from Tod.

Quote: "I'm ready to start machining but can't get near a machine. The machine I was going to have time on is busy with my former blocks and has been sold on top of that. My fall-back machine is busy through March. I keep taking a back seat to everyone. I have been talking to my bank about financing my own machine so I can machine blocks when I want, plus all of the other machining that is coming my way."

"In the mean time I am doing other work to fill my time and I will be talking to an iron foundry today about casting a sample iron block or two. This will allow me to have both aluminum and iron ready to machine when I either get machine time or get my own machine. Trust me people, I'm more sick of waiting on other people than you are of waiting on me. I have 14 or 15 deposits on aluminum. I don't want to keep these good gentlemen waiting and wondering. (The money is all sitting in it's own dedicated account)."

Quote: "I'm ready to start machining but can't get near a machine. The machine I was going to have time on is busy with my former blocks and has been sold on top of that. My fall-back machine is busy through March. I keep taking a back seat to everyone. I have been talking to my bank about financing my own machine so I can machine blocks when I want, plus all of the other machining that is coming my way."

"In the mean time I am doing other work to fill my time and I will be talking to an iron foundry today about casting a sample iron block or two. This will allow me to have both aluminum and iron ready to machine when I either get machine time or get my own machine. Trust me people, I'm more sick of waiting on other people than you are of waiting on me. I have 14 or 15 deposits on aluminum. I don't want to keep these good gentlemen waiting and wondering. (The money is all sitting in it's own dedicated account)."

I saw Tod has posted that he is getting his own mill in about two weeks. Just thought Id let you guys know.

Tod's Newest

Jeff

Tod's Newest

Jeff

This is the latest news from Tod linked in Jeff's post:

Quote: "About two weeks and my machine will be here. I am buying a Mazak H500/50. In the mean time I am scheduled to sample iron blocks. When the machine arrives I will be cutting aluminum and iron blocks."

Quote: "About two weeks and my machine will be here. I am buying a Mazak H500/50. In the mean time I am scheduled to sample iron blocks. When the machine arrives I will be cutting aluminum and iron blocks."

Attachments

quote:I am buying a Mazak H500/50.

A little web searching shows that to be about a $50,000 machine.

Larry

That looks to be a nice twin pallet machining centre.

I used to program those things for a living !

I used to program those things for a living !

Gentlemen,

Tod has hit another delay beyond his control on his way to providing the new 351C blocks. Tod is tired of having to disappoint his customers in delaying filling their PAID orders for his 351C block, he's frustrated by this latest development.

If you have been keeping up with Tod’s posted updates, you know that he has been frustrated in his attempts to have his new blocks machined commercially by others. So, he decided to buy his own CNC machine. He had one located, and put up the funds. Here is an outline of what has happened since.

Tod provided funds to a Dealer to purchase a Mazak H500/50 from a shop (Seller).

The Dealer stated the Mazak would be available in a couple of weeks, based on information the Dealer received from the Seller.

The Funds from Tod were transferred to the Dealer. Delivery was anticipated.

The Mazak would be up and running now except for the new set back:

The Seller’s new machine needs repairs, and will not be available for delivery for up to five weeks. In the meantime, the Mazak is still in use by the Seller. The Seller is delaying the sale of the Mazak until his new machine is delivered.

The owner of the Cleveland Forum has spoken with the dealer and verified this information.

George

Tod has hit another delay beyond his control on his way to providing the new 351C blocks. Tod is tired of having to disappoint his customers in delaying filling their PAID orders for his 351C block, he's frustrated by this latest development.

If you have been keeping up with Tod’s posted updates, you know that he has been frustrated in his attempts to have his new blocks machined commercially by others. So, he decided to buy his own CNC machine. He had one located, and put up the funds. Here is an outline of what has happened since.

Tod provided funds to a Dealer to purchase a Mazak H500/50 from a shop (Seller).

The Dealer stated the Mazak would be available in a couple of weeks, based on information the Dealer received from the Seller.

The Funds from Tod were transferred to the Dealer. Delivery was anticipated.

The Mazak would be up and running now except for the new set back:

The Seller’s new machine needs repairs, and will not be available for delivery for up to five weeks. In the meantime, the Mazak is still in use by the Seller. The Seller is delaying the sale of the Mazak until his new machine is delivered.

The owner of the Cleveland Forum has spoken with the dealer and verified this information.

George

GREAT NEWS!

The latest news from Tod:

Quote: "Okay. After all the crap I've endured, the machine I found to replace the one I bought a couple of weeks ago is here. Sitting on the shop floor ready to wire up and level. Everything went off without a hitch."

"On top of this I got the oil slinger and rear seal tools through UPS today (they are perfect) and the Erson roller timing chain set I bought just to use for checking for any possible clearance issues in the front of the castings. It looks great."

"And it didn't even rain."

Tod

The latest news from Tod:

Quote: "Okay. After all the crap I've endured, the machine I found to replace the one I bought a couple of weeks ago is here. Sitting on the shop floor ready to wire up and level. Everything went off without a hitch."

"On top of this I got the oil slinger and rear seal tools through UPS today (they are perfect) and the Erson roller timing chain set I bought just to use for checking for any possible clearance issues in the front of the castings. It looks great."

"And it didn't even rain."

Tod

Not to be a stick in the mud here but who is going to the durabilaty testing first?

I have a depsoit on one, so I guess I'm one of the 15 or so 'durability' testers for the first batch of Al blocks.

How do we "season" analuminum block? Besides salt and pepper, that is.

That thing is going to squirm around like sillyputty?

I'm sure the big billet main caps with the splayed bolts will help but does anyone know?

Wow! Now I got myself thinging? Look out Doug is thinking again! These blocks aren't going to be too stable for a stroker crank now are they?

That thing is going to squirm around like sillyputty?

I'm sure the big billet main caps with the splayed bolts will help but does anyone know?

Wow! Now I got myself thinging? Look out Doug is thinking again! These blocks aren't going to be too stable for a stroker crank now are they?

I plan on doing a little bit of durability testing myself.

I know when we made the parts for the Corvette we used to artificially 'age' the aluminium. You will find this will be done to the al blocks, to help with stability.

Durabilty or Seasoning .... durabilty ? send it to me and I will put it in my pantera and test it for you .... LOL .... seasoning can be done with a cleaning oven at any engine builders shop or put it in another vehicle and drive it.

Ron

Ron

Seasoning is a minor issue with aluminum since it does not retain the residual stresses during the casting process like iron does. Those of you you have an aluminum block coming should not consider it an issue.

The Latest News From Tod:

Quote: "After assembling a mold Friday and having the block poured on Saturday, and waiting all weekend for results, I saw the first iron block come out of shot blast this morning. So far, so good. Aside from some expected burn-in, the block looks good. No holes. Solid in all the troublesome areas. The foundry will work on clean up and this afternoon I will take pictures of the cleaned block. I was very pleased with the results. Now I have aluminum and iron samples, and a machine that is up and running. Get ready boys!"

Tod

Quote: "After assembling a mold Friday and having the block poured on Saturday, and waiting all weekend for results, I saw the first iron block come out of shot blast this morning. So far, so good. Aside from some expected burn-in, the block looks good. No holes. Solid in all the troublesome areas. The foundry will work on clean up and this afternoon I will take pictures of the cleaned block. I was very pleased with the results. Now I have aluminum and iron samples, and a machine that is up and running. Get ready boys!"

Tod

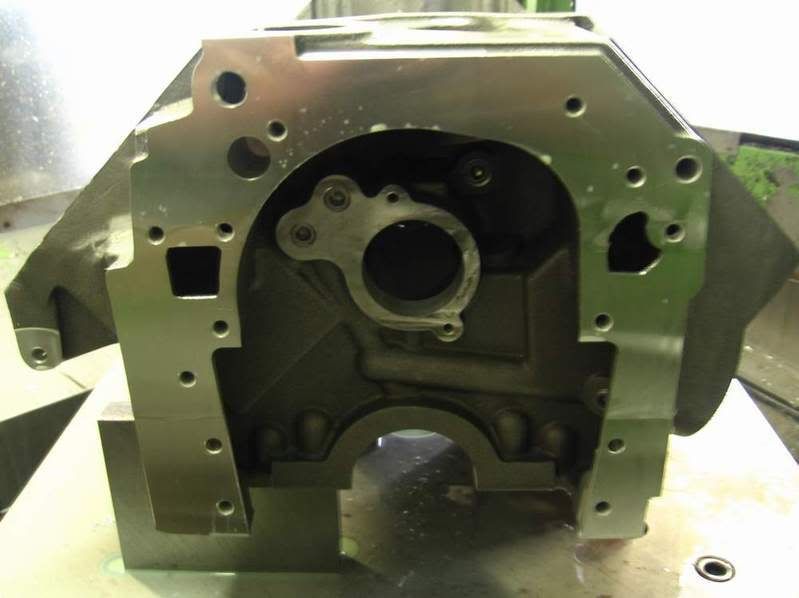

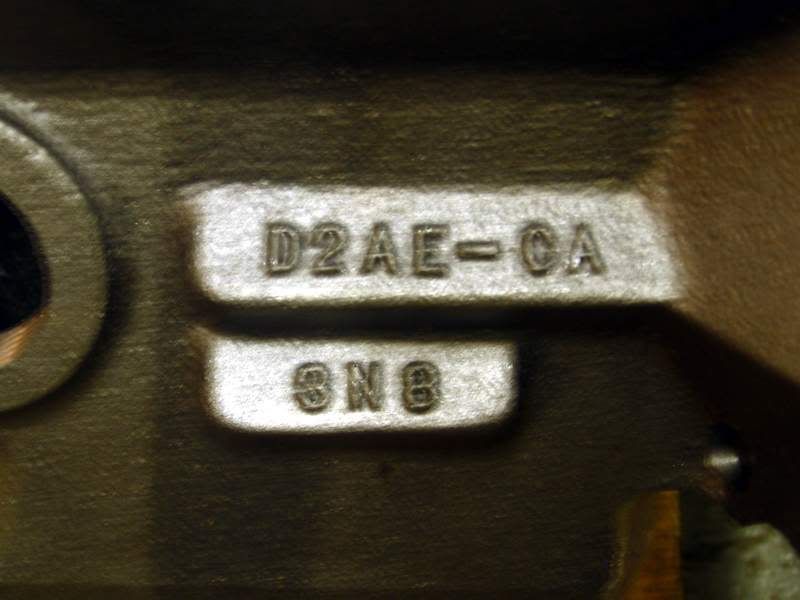

Another update from Tod

Quote: This is the block that was pictured in an earlier post. It has some casting issues. My friend Tom Hoover pulled the distributor out of a 1970 Cleveland that was in a wrecked car. He has had it for quite a while. Only has about 10k miles on it. We talked about using its parts to build this block up stock and see how it goes.

The issues I ran into were:

1. Casting was somehow made .100 too thick. I adjusted machining to make it only .080 heavy. Because the casting is too thick the distributor pocket is machined in deeper than designed.

2. I screwed up and forgot the oil galley boss metal in the valley, so you can see the weld put in before machining. It looks bad but doesn't leak. The pattern has been modified, and is ready for new castings.

3. Because I changed a drill diameter and angle, I nicked the passenger waterjacket when I drilled the front oil passage from the front main to the main oil galley. Block fill will fix it for our test build. This will not be an issue from here out. I added stock to the corner that was nicked.

4. I forgot to put the distributor hold down bolt boss in the cross-over water passage core box. What an idiot!!! I have already altered that. This block will be welded and fixed by hand. Pretty easy fix.

If anyone sees anything that raises red flags let me know. I'm anxious to get blocks to the guys waiting patiently for their product. The iron guys are starting to email me.

BTW splayed caps will be the norm in production.

Sorry for taking so long.

Tod

Quote: This is the block that was pictured in an earlier post. It has some casting issues. My friend Tom Hoover pulled the distributor out of a 1970 Cleveland that was in a wrecked car. He has had it for quite a while. Only has about 10k miles on it. We talked about using its parts to build this block up stock and see how it goes.

The issues I ran into were:

1. Casting was somehow made .100 too thick. I adjusted machining to make it only .080 heavy. Because the casting is too thick the distributor pocket is machined in deeper than designed.

2. I screwed up and forgot the oil galley boss metal in the valley, so you can see the weld put in before machining. It looks bad but doesn't leak. The pattern has been modified, and is ready for new castings.

3. Because I changed a drill diameter and angle, I nicked the passenger waterjacket when I drilled the front oil passage from the front main to the main oil galley. Block fill will fix it for our test build. This will not be an issue from here out. I added stock to the corner that was nicked.

4. I forgot to put the distributor hold down bolt boss in the cross-over water passage core box. What an idiot!!! I have already altered that. This block will be welded and fixed by hand. Pretty easy fix.

If anyone sees anything that raises red flags let me know. I'm anxious to get blocks to the guys waiting patiently for their product. The iron guys are starting to email me.

BTW splayed caps will be the norm in production.

Sorry for taking so long.

Tod

Very nice looking piece. When you undertake a project like this there are bound to be some issues. Thats what the test block is for. I say great job Tod. There are going to be some very happy individuals out there. I look forward to seeing these in some Panteras in the near future.

Blaine

Blaine

Another update from Tod

quote:I have had cores at the foundry for at least 2 weeks now. My only(non-Cleveland) customer has had a quote owed to him from the same foundry for at least a month. A friend of mine is in the process of setting up a foundry. I was at the new facility yesterday. He thinks he is 3-4 weeks away from pouring metal. If I have to wait that much longer where I am I will have him pour my block. Needless to say, he will be doing my work anyway. I can't even get a return call from Quaker City Castings. When I am looking at sending hundereds of thousands of dollars of work somewhere, I expect returned calls.

In short, I am still being held up by other people. This is why I used to have the whole shabang when I was in Indianapolis.

Tod

Thanks for the update. I think that I understand how he feels.

Those things are beautiful.

Let me ask this now, are the main webs on Todd's block thicker like the "Nascar" blocks? Looking at the pictures it's hard to tell.

Those things are beautiful.

Let me ask this now, are the main webs on Todd's block thicker like the "Nascar" blocks? Looking at the pictures it's hard to tell.

The latest update from Tod as of 12/13/08:

quote:

Since I have been waiting for 2 months to get a casting from Quaker City Castings, which caused me to miss having one displayed in Barry Rabotnik's booth at PRI, I am going to use the cores to cast an iron block. My friend is pouring iron now and is working on the aluminum furnace setup. There is no sense letting the cores sit any longer when I can at least make an iron block with the new revisions. I am truly sorry for the delay on the aluminum side of this. I never saw this coming.

Fortunately, I have been able to feed myself by doing some work for Snyder's Antique Auto. While forced to wait on castings I have been developing new parts for him and fixturing up to machine sveral others. I plan to add a Model A block to the mix sometime next year, after I get the C block up and running.

Times are getting tough and I will do my best to offer my Cleveland at the best price I can for you loyal supporters. You can't really know how much I appreciate the patience, support, and concern for my health that you have shown to a guy you don't even know. (BTW, I feel terrible but at least I'm alive and can work everyday until I hit the wall.)

Oh yeah, almost forgot. At thanksgiving my brother-in-law asked what I was going to do with the first sample that had some flaws in the casting. A friend was thinking about building it, but my brother-in-law said he wouldn't think about it, he would do it. So...he now is in the process of fixing the block and is going to put it in a Cobra kit he bought a couple of years ago. When he came to the shop to get it he looked like a kid in a candy store. He never stopped smiling.

Tod

The latest update from Tod as of 1/13/09

quote:

Due to the delay of getting into production I am going to reduce the price of the first 15 aluminum blocks to $2300.00.

I understand that the economy is bad and I will do what I can to help Cleveland enthusiasts. Three individuals have had to cancel their aluminum block orders due to the long wait and other factors that have developed in the mean time. I have sent their money back as they requested. This allows those of you who I told to hold your money to step into the 3 open spots. If I have to order more sleeves to expand the first run to 20-25, I will do it.

I am as anxious as any of you to get this project up and running. It is my goal to start producing blocks soon so that the drag racers on the Cleveland Forum can have a block for the new season.

Tod

They do look good

Very tempting !!

Very tempting !!

Those blocks look great. Wish the economy was better right now also. I would love to have one of the aluminum blocks. So when is Tod going to design and cast his own head for the Cleveland? I know...let him get the block done first.

Wow $2300 is a steal, compare to the cost of a Fontana or Dart block. With all the development costs there can't be any margin in this for Todd.

My deposit went on one of the first 15, now I'm wondering whether to get another, one for each Pantera!

Julian

My deposit went on one of the first 15, now I'm wondering whether to get another, one for each Pantera!

Julian

anyone have tod new email? his tlb427@sbcglobal.net does not work. thanks

try

tlb427351@yahoo.com

tlb427351@yahoo.com

Another update from Tod as of 1/18/09:

quote:

The new foundry had me order two more sets of cores so we can pour two aluminum blocks after we pour the first iron one (first for him). I would like to have something for the show in Columbus, at least it is my current plan. I don't think Trumbull Metals will be holding me up for months on end like Quaker City Castings did. I was going to mold the iron casting Friday 1/16/09 but they ran out of part A binder chemical which will be delivered 1/19. I had my camera ready to take some pics of the place and molding when I got Corey's message about the delay. He is really ready to work on these things. This next week we will be getting the process started.

I have also secured a boring head for the cam bores. I am working with Big Kaiser to get the tools ready to go. This will allow me to bore the cam and cranks within 5 or 10 thousandths so the builders will only need to hone them to size. I also have Trumbull casting a Third OP machining fixture for the blocks. This fixture allows proper placing of the cam and crank from both decks.

If anyone feels complelled to verify anything I am saying with Trumbull Metal Specialties you can reach Corey Jarvis at 330-349-4505 or email him at corey@trumbullmetal.com. I worked with him on the FE blocks when he was at another foundry. I believe that foundry is still making the FE blocks for Pond when he needs them.

BTW, Pond re-set the NHRA A Stock record with one of our iron blocks.

Tod

Trumbull Metals is pouring blocks. This one is iron.

When was this iron block poured? How did the machining go? Everything turn out O.K.? Any word on when the aluminum blocks will be trialed?

Very interesting to say the least.

Very interesting to say the least.

It was poured last week. I have not machined it yet. I checked it over and did not see any reason yet that it will not make a good block. Ofcourse, the machinist(me) could screw it up. Let's hope not. I have two sets of cores for aluminum blocks already delivered to the foundry.

Tod

Tod

This is great stuff Tod! We look forward to more updates as things progress.

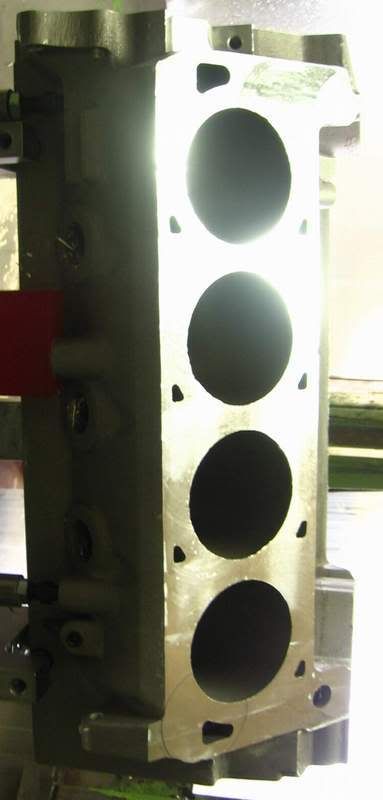

Tod's iron block after its been machined

nice looking block...it would be interesting to put one of Tod's new iron blocks and an original 351c block side by side to compare quality. My bet would be for Tod's block.

An update from Tod 4/11/09

quote:Quoting Tod Buttermore:

Yesterday we finally poured the first aluminum at Trumbull Metal Specialties. I was the test subject. We poured one block and 2 aluminum Model A high compression heads. The heads are for Snyder. WOW. Very nice castings. We used a graphite mold wash that gave the block a very nice finish right out of the sand. Everything looks good. I will machine it asap and have somebody finish machine it and build it. We're getting there boys.

Tod

Here are the pictures of the aluminum block poured at Trumbull Metal Specialties on 4/10/09:

Great Work Tod ... man I'm getting excited!

Great Work Tod ... man I'm getting excited!

Add Reply

Sign In To Reply