Another update from Tod

quote:

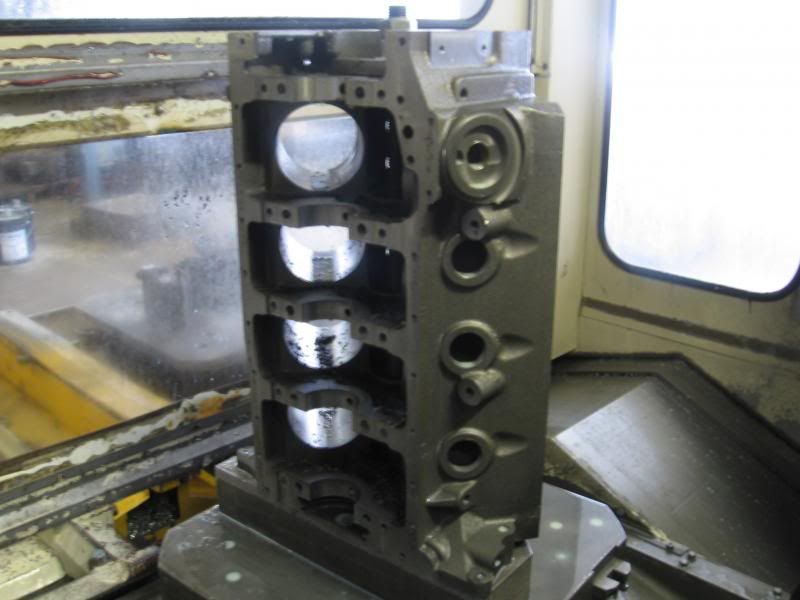

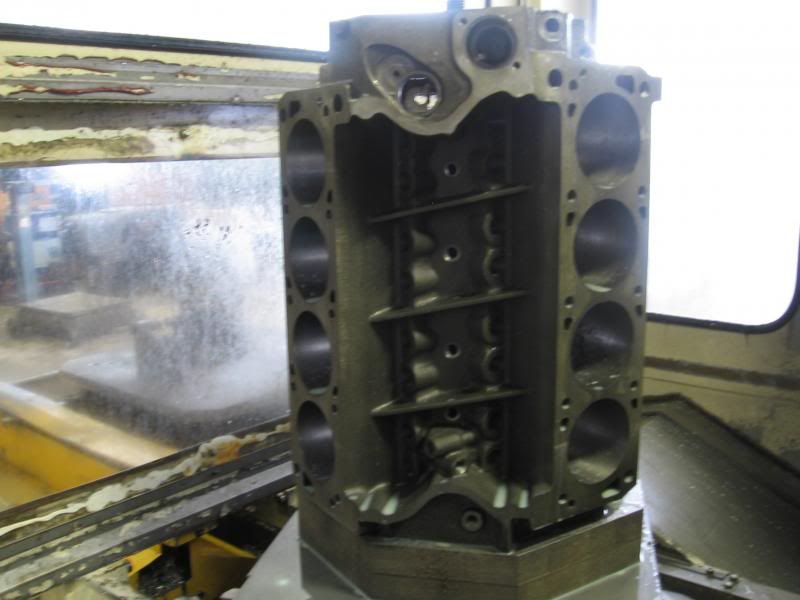

I am being inundated with work requests right now. It is nice to be able to run regular production without stopping to machine a block or two. The second machine center was a good buy. There are currently 3 pallets and I am trying to buy more so I can run other stuff too, without set up time.

The real suprise is that my foundry is actually wanting to cast blocks now! They bought a second building and have more than tripled their space so they need the work. Good.

I just purchased a couple of additional boring tools to make boring the mains and cylinders easier. Can't wait to get to that point.

Tod

-G