OK, take 2.....

Back on the Goose again, after about 10 weeks of little to no proper progress!

Spent some time looking into finding a new idler pulley standoff, for the front of the engine, but this turned out to be a "goose" chase...of sorts! Will have one made....

Worked on getting some new parking brake cables made up, but no luck finding the eyelets for the small 3mm cable! I found cable, sheathing, and ferrels that can be modified to fit, but no eyelets! My contact is still working with some old prints.... we'll see what happens..... May just end up brazing my old ends back on.....

Something completely different: rear disc brake kits for old Ford 8 & 9" rear ends....trying to reorder parts, but now instead of costing about $3 each, they want $6! Even when the quantity is for 400! I thought we were in a recession where shops were hungry for work?????

When my car was repaired, the work that was done looked fantastic! However, upon closer examination, and when I started bolting up the other parts that all reside in this "one ton of crap in a half ton truck" area of the frame, I ran into problems with things fitting.

A hole for the sway bar mounting clamp was drilled in the wrong location and needed to be relocated. Also, the upper shock mount portion of the repair looked fantastic, but it must have slipped position before it was welded into place, because in the end, it was crowding the other parts such that bolts would not fit properly into the other mounts, or wrenches no longer fit, or the bolts rubbed the sway bar worse than before.....and being the picky SOB that I tend to be sometimes, I just couldn't see slapping it together....cuz I know it would just bother me knowing it was there!!!

I think these cars are special, and deserve proper care and repair! So, I'm taking a little time and redoing it properly. I hope.

First, I carefully removed the repaired mount, using a thin Dremel wheel where possible, and thin hacksaw blades in the odd corners and finally got it off, preserving as much metal as I could.

I then cut off a bolt, and recessed it into the maligned hole, and tonite, welded it in place, filed it down flush, and drilled and tapped it. Came out very nice, and the sway bar clamp now sits where it should!

I still may have some interference with the sway bar and the bolt heads of the top ZF mount. I had this before....and I am thinking that I may make up some 1/2" spacers to put underneath these sway bar mounts, to lift the clamps up above the bolt heads. Would only require 1/2" longer bolts.....not a big deal. Will see when I put everything back in place......whether they will be needed or not.

I finally used my new bushing tools and pushed out the old upper ZF mount ends, and cleaned up any protruding welds with a file, cleaned and greased the holes, and pushed in the new bushings! Other than some resistance getting the old rusted ones out, a little PB Blaster helped loosen one stuck one up(!), the job went quite well and the custom tools worked as they should!

I used a 6ton bench top press to get the old bushings out. I used the same to push the bushing back in on one side, but on the other side I experimented with a large c-clamp and it installed the new bushing just fine! I was able to fine tune the fore-aft position of the bushing with the c-clamp very nicely!

Here is a shot of one new bushing in place. If the center looks off center, it is. I used these briefly in a set of factory shocks, found the shocks were bad, and pulled the shocks, took the bushings out and saved them for this job! They will settle back to center when weight is put on them.

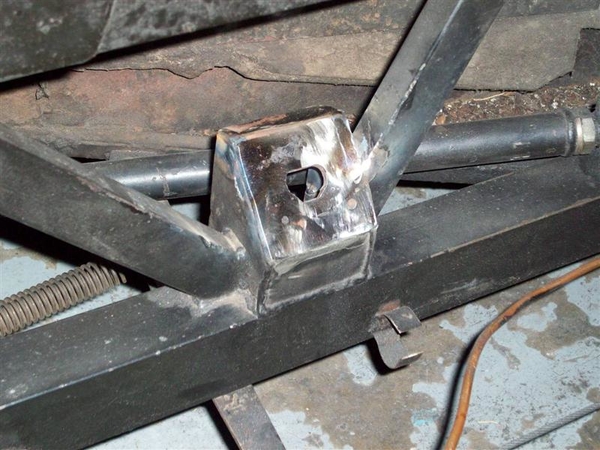

Another project I've been toying with, is a means to support the upper frame sections, from side to side, to eliminate the flex that is allowed by the bushings in the ends of the upper ZF mount. As Dick Ruzzin pointed this out, and went on to re-engineer the entire mounting and ZF support system of his car with a very involved repair or implementation, it got me thinking. Here is my very simple solution to at least part of the problem.

This is a solid bar, that with longer bolts, should be a simple affair that will strengthen the top of the frame sections by tying them together and will limit their ability to move.

While it does nothing to strengthen the area where the upper a-arms attach to the bottoms of the top frame rails, it is a start. And it only weighs in at one pound!

I measured the ZF cross mount center to center hole dimension and drilled the same dimension into this bar. Your car may vary slightly from what is shown!!!! I had to put some weight on the wheels to get the bolts back in, as having them unloaded (wheels hanging) pulled the top of the frame outwards slightly making it impossible to put the bolts in.

I have some spacers to make yet so that this bar doesn't interfere with the two ZF bolts, and I will need slightly longer bolts at the ends to snug it in place. I will also contour the ends to remove the square ends... Most of this will never be seen if you carry a spare tire....

Next? Getting that upper shock mount tower put back onto the chassis! Stay tuned!

This mirrors what the factory originally did on the RH side to make up for the notch in the frame to accommodate the shifter linkage.

This mirrors what the factory originally did on the RH side to make up for the notch in the frame to accommodate the shifter linkage.