As I build this thread, I realize how much I owe to my mentor and friend, Wade (4280 / Mark IV).

From the start of my Pantera experience, he has been happy to give me a hand, first with carburetor and distributor advice, and improvement, and then with spectacular fabrication work on both the body and the engine.

Wade has really upgraded this car in one sweeping pass. Some improvements have been required (rust in the upright, ZF Safety Wire), many are to maximize performance (Ported Heads and Manifold, Carburetor work), and others are just for fun (engine build, bay paint).

I feel that in this build, the whole will be far bigger than the sum of the parts.

I am really looking forward to getting the car back on the road, and I owe Wade (4280 / Mark IV) a big "Thank You"! (And maybe a scotch or two!)

Rocky

PS: Best wishes to all as you head to the Fun Rally - I wish I was going!

Can't wait to see it back on the road!

Joe

Joe

Answer's to JFB and Rodney (UFO-LOW).

The edging material is from Elliot Electronics in Tucson (but we both suspect it can be obtained at any well stocked electronics supply store - maybe even Radio Shack), it is designed for irregular holes to prevent chaffing.

JFB - with regards to the bushings, they are a standard metric size - the id/od/length are mm dimensions 24 x 27 x 29 long.

You may be able to pick them up at a standard bushing house....

The edging material is from Elliot Electronics in Tucson (but we both suspect it can be obtained at any well stocked electronics supply store - maybe even Radio Shack), it is designed for irregular holes to prevent chaffing.

JFB - with regards to the bushings, they are a standard metric size - the id/od/length are mm dimensions 24 x 27 x 29 long.

You may be able to pick them up at a standard bushing house....

Couple of Updates...

Motor goes in tomorrow (that's the plan, anyway).

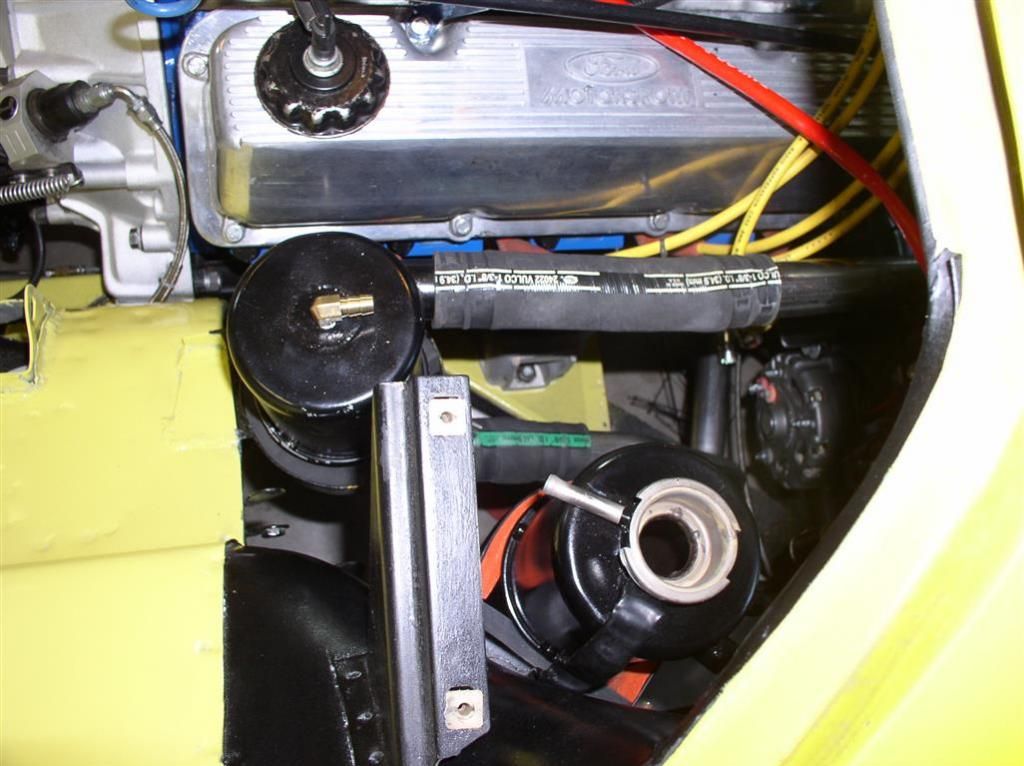

Here's the fuel system (pump & lines)....

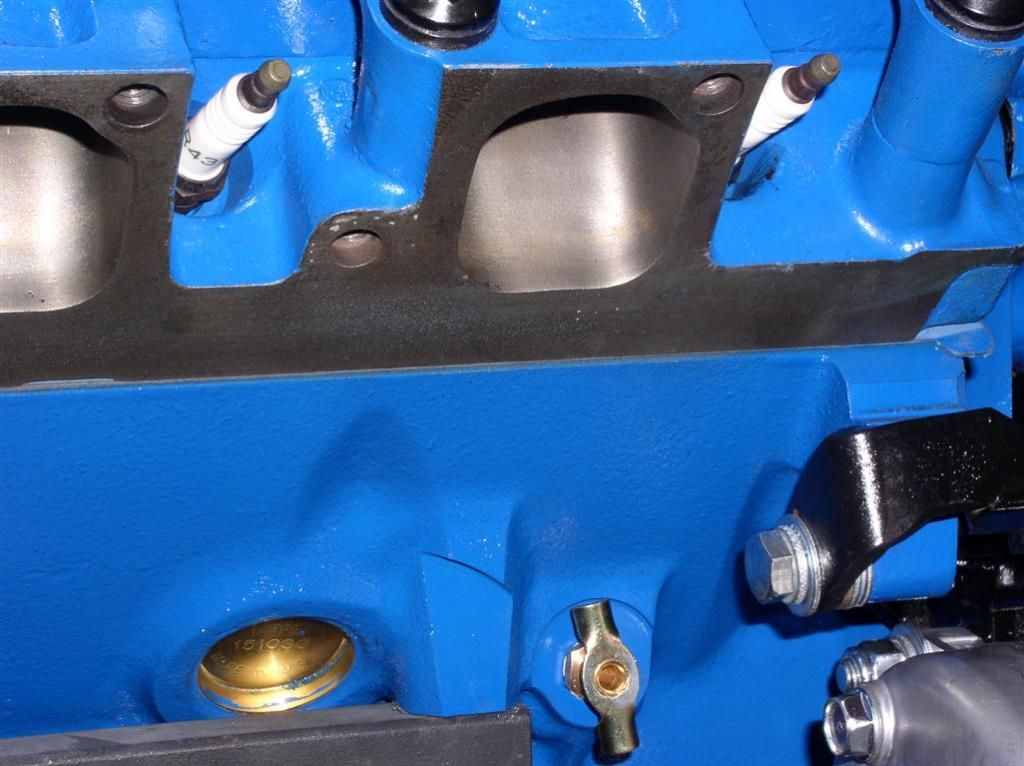

Newly ported Edelbrock Performer Intake Manifold.

There was a lot of material in there that was removed. The porting was done to match the outline of the gasket, which had been previously verified to be highly representative of the port size and shape.

Don't want my heads to be restricted by the manifold that feeds it!

OK - Back to work!

Rocky

Motor goes in tomorrow (that's the plan, anyway).

Here's the fuel system (pump & lines)....

Newly ported Edelbrock Performer Intake Manifold.

There was a lot of material in there that was removed. The porting was done to match the outline of the gasket, which had been previously verified to be highly representative of the port size and shape.

Don't want my heads to be restricted by the manifold that feeds it!

OK - Back to work!

Rocky

hope you had a productive day!

Engine Install Day! One giant leap forward for my project!

What a feeling of progress!

Wade came by and we knocked out a big chunk of the "endgame" work. We got the motor checked out, and installed. Lots of little items that had been on hold were accomplished. Here's some highlights....

Motor Mounts and Formed Heater Hoses...

There is a shielded sleeve for my heater control valve. This valve will be operating in the engine bay, vs. in the cockpit. The formed hoses are the shizzle for the Pantera application.

The brown wire will mount to the oil temp sender in the front of my Avaid 10 Qt oil pan. The plan is to wire it through the "spare" switch on the dash, so I can check oil or water temp with the flip of a switch.

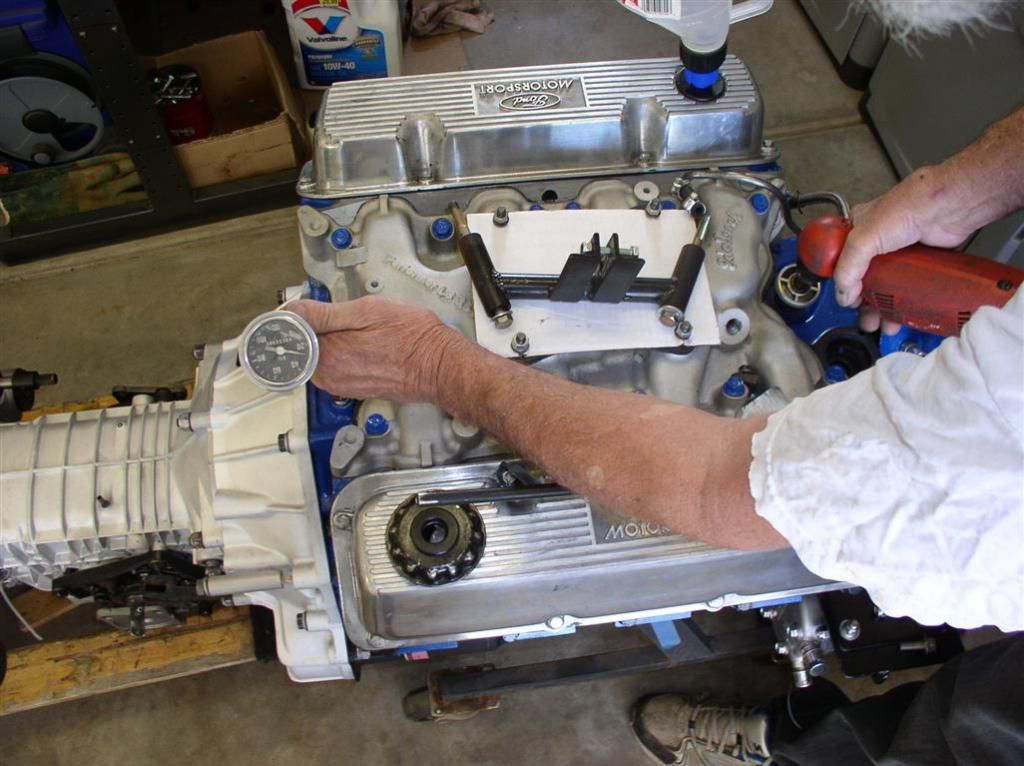

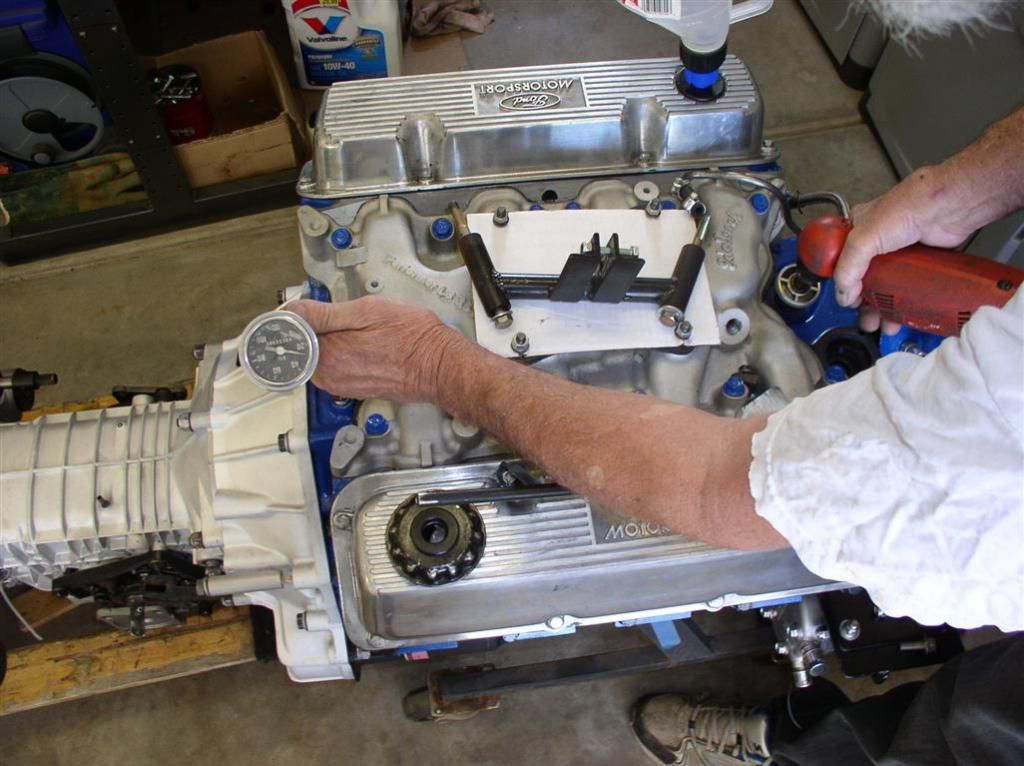

Oil Pressure Verification - SUCCESS!

A broken distributor and a drill makes a cool oil pump driver. A spare oil pressure gauge tells the tale. At idle speed (actually, well below it) the motor was registering 25-30 psi. At slightly higher rpm, the oil pressure relief was opening at 75-80 psi. Just as we had planned.

An Old Racer's Trick - Right Steve?

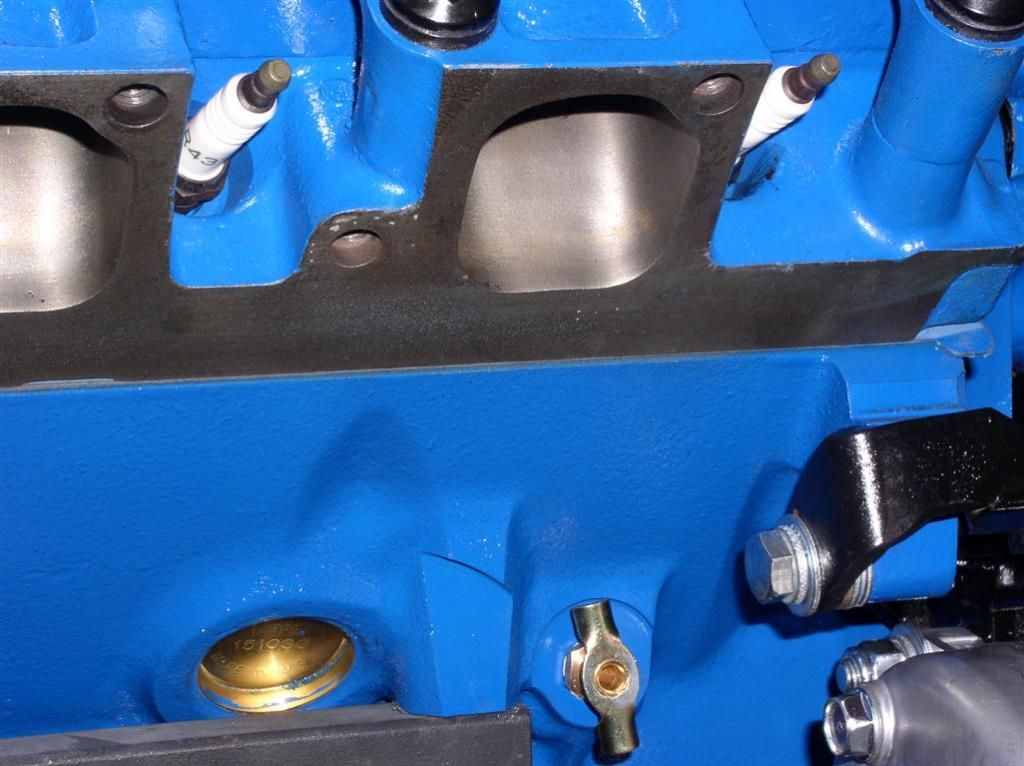

These petcocks on both sides of the block let you drain down the coolant when needed. This allows you to make much less of a huge mess.

I would venture to say that these petcocks add about 5-6% more cowbell to my engine build (each!).

In She Goes...

Not much more to say here...

In The Bay!

Still have to do electrical checks, ZF Fill, coolant fill, and some work is still needed on the exhaust, Bulkhead Cover (alternator clearance) and lots of other little stuff. But the day will soon arrive for the break-in and then... the sky is the limit.

Rocky

What a feeling of progress!

Wade came by and we knocked out a big chunk of the "endgame" work. We got the motor checked out, and installed. Lots of little items that had been on hold were accomplished. Here's some highlights....

Motor Mounts and Formed Heater Hoses...

There is a shielded sleeve for my heater control valve. This valve will be operating in the engine bay, vs. in the cockpit. The formed hoses are the shizzle for the Pantera application.

The brown wire will mount to the oil temp sender in the front of my Avaid 10 Qt oil pan. The plan is to wire it through the "spare" switch on the dash, so I can check oil or water temp with the flip of a switch.

Oil Pressure Verification - SUCCESS!

A broken distributor and a drill makes a cool oil pump driver. A spare oil pressure gauge tells the tale. At idle speed (actually, well below it) the motor was registering 25-30 psi. At slightly higher rpm, the oil pressure relief was opening at 75-80 psi. Just as we had planned.

An Old Racer's Trick - Right Steve?

These petcocks on both sides of the block let you drain down the coolant when needed. This allows you to make much less of a huge mess.

I would venture to say that these petcocks add about 5-6% more cowbell to my engine build (each!).

In She Goes...

Not much more to say here...

In The Bay!

Still have to do electrical checks, ZF Fill, coolant fill, and some work is still needed on the exhaust, Bulkhead Cover (alternator clearance) and lots of other little stuff. But the day will soon arrive for the break-in and then... the sky is the limit.

Rocky

Cool Trick - When You Drop a Nut inside a Non-Ferrous surface... (Like in the Motor Mount)

A magnet ball inside a baggie can get in where your fingers can not.

I am sure this would work in a magnetic area as well, you just have to figure out a way to get the magnet into the area where the missing hardware is located.

A magnet ball inside a baggie can get in where your fingers can not.

I am sure this would work in a magnetic area as well, you just have to figure out a way to get the magnet into the area where the missing hardware is located.

Attachments

I didn't understand about the heater control valve. did you take a photo of its installed position?

It's not in quite yet...

I'll try and post up a picture of the valve style....

I'll try and post up a picture of the valve style....

Rocky,

Nice job on the petcocks! Now I I could just remember where I saw that before.

Remote heater valve is the way to go. I did an electronic one but still good idea to get it out of the cabin. I'm looking forward to hearing you got it out on a shakedown cruise.

Steve.

Nice job on the petcocks! Now I I could just remember where I saw that before.

Remote heater valve is the way to go. I did an electronic one but still good idea to get it out of the cabin. I'm looking forward to hearing you got it out on a shakedown cruise.

Steve.

quote:Originally posted by T.Solo:

I did an electronic one but still good idea to get it out of the cabin.

Steve.

Steve, How did you control the coolant flow through the valve or is it simply full open or fully closed?

Doug M

* * UPDATE * * Cable Controlled Heater Valve

I found the cable controlled heater valve that recirculates to the pump when the valve is in the closed position. This valve cost about $18 at the local parts store.

This valve will be going in the engine bay, and will eliminate flow into the cockpit when shut off. I am using a cable system from the original heater lever. We will have to fab up a little bracket / cable clamp to mount the cable, and to position the bracket in the engine bay area.

[url]=http://s1298.photobucket.com/user/Rocky_LC/media/351C%20Engine%20Build%202013/06-26-2014108Medium_zps82ad7750.jpg.html]

[/url]

[/url]

[url]=http://s1298.photobucket.com/user/Rocky_LC/media/351C%20Engine%20Build%202013/06-26-2014111Medium_zps1734910d.jpg.html]

[/url]

[/url]

[url]=http://s1298.photobucket.com/user/Rocky_LC/media/351C%20Engine%20Build%202013/06-26-2014110Medium_zps583cfaf4.jpg.html]

[/url]

[/url]

I am removing the original valve in the front - it is VERY stiff, and just replacing it with a 90 Deg. brass elbow.

* * * Another Update - Electronic Heater Valve! * *

This is an electronic version of the one that Wade and I are working on.

Electronic Remote Heater Valve

Dave (2811) has one of these babies, as you can see in his picture (Post #2 of this thread)

Dave 2811 Remote Heater Valve

Rocky

The old valve I posted will be going back onto eBay when I get some time. It's not really what I was looking for.

I found the cable controlled heater valve that recirculates to the pump when the valve is in the closed position. This valve cost about $18 at the local parts store.

This valve will be going in the engine bay, and will eliminate flow into the cockpit when shut off. I am using a cable system from the original heater lever. We will have to fab up a little bracket / cable clamp to mount the cable, and to position the bracket in the engine bay area.

[url]=http://s1298.photobucket.com/user/Rocky_LC/media/351C%20Engine%20Build%202013/06-26-2014108Medium_zps82ad7750.jpg.html]

[/url]

[/url][url]=http://s1298.photobucket.com/user/Rocky_LC/media/351C%20Engine%20Build%202013/06-26-2014111Medium_zps1734910d.jpg.html]

[/url]

[/url][url]=http://s1298.photobucket.com/user/Rocky_LC/media/351C%20Engine%20Build%202013/06-26-2014110Medium_zps583cfaf4.jpg.html]

[/url]

[/url]I am removing the original valve in the front - it is VERY stiff, and just replacing it with a 90 Deg. brass elbow.

* * * Another Update - Electronic Heater Valve! * *

This is an electronic version of the one that Wade and I are working on.

Electronic Remote Heater Valve

Dave (2811) has one of these babies, as you can see in his picture (Post #2 of this thread)

Dave 2811 Remote Heater Valve

Rocky

The old valve I posted will be going back onto eBay when I get some time. It's not really what I was looking for.

Attachments

quote:

Steve, How did you control the coolant flow through the valve or is it simply full open or fully closed?

Doug M

Doug, I will send you a PM. Don't want to steal Rocky's post.

Headers -

So my car came with a set of "Big Bore" headers (at least that's what I think they are). Looking at them, they were coated, and in good shape, but when looking in the collectors, we noted significant restrictions to flow. Since we were optimizing flow in this engine build with porting of the intake manifold, intake ports in the heads, and the heads themselves, it didn't make any sense to have restriction in the exhaust.

![photo 06-17-20141Medium_zps3b9d943d.jpg~original[/IMG] </a><BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20141Medium_zps3b9d943d.jpg)

![photo 06-16-20145Medium_zps83eaaf0f.jpg~original[/IMG] </a><BR> <BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-16-20145Medium_zps83eaaf0f.jpg)

![photo 06-17-20144Medium_zpsfe354a8b.jpg~original[/IMG] </a><BR><BR>The header attachment bolts were machined with a locating boss in the bolt flange. This allows a more positive header alignment, and helps to prevent the bolts from loosening up. It's a little tougher to see in these pictures.<BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20144Medium_zpsfe354a8b.jpg)

![photo IMG_1229Medium_zpsb3289aa1.jpg~original[/IMG] </a><BR><BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/IMG_1229Medium_zpsb3289aa1.jpg)

![photo 06-17-20148Medium_zpsa943d280.jpg~original[/IMG] </a><BR><BR>Tubing to the mufflers will be upgraded to 2-1/2](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20148Medium_zpsa943d280.jpg)

Rocky

PS. This is another example of master craftsmanship by Mark IV / 4280 - thanks, Wade for the help.

So my car came with a set of "Big Bore" headers (at least that's what I think they are). Looking at them, they were coated, and in good shape, but when looking in the collectors, we noted significant restrictions to flow. Since we were optimizing flow in this engine build with porting of the intake manifold, intake ports in the heads, and the heads themselves, it didn't make any sense to have restriction in the exhaust.

![photo 06-17-20141Medium_zps3b9d943d.jpg~original[/IMG] </a><BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20141Medium_zps3b9d943d.jpg)

![photo 06-16-20145Medium_zps83eaaf0f.jpg~original[/IMG] </a><BR> <BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-16-20145Medium_zps83eaaf0f.jpg)

![photo 06-17-20144Medium_zpsfe354a8b.jpg~original[/IMG] </a><BR><BR>The header attachment bolts were machined with a locating boss in the bolt flange. This allows a more positive header alignment, and helps to prevent the bolts from loosening up. It's a little tougher to see in these pictures.<BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20144Medium_zpsfe354a8b.jpg)

![photo IMG_1229Medium_zpsb3289aa1.jpg~original[/IMG] </a><BR><BR><BR><a href=](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/IMG_1229Medium_zpsb3289aa1.jpg)

![photo 06-17-20148Medium_zpsa943d280.jpg~original[/IMG] </a><BR><BR>Tubing to the mufflers will be upgraded to 2-1/2](http://i1298.photobucket.com/albums/ag42/Rocky_LC/351C%20Engine%20Build%202013/06-17-20148Medium_zpsa943d280.jpg)

Rocky

PS. This is another example of master craftsmanship by Mark IV / 4280 - thanks, Wade for the help.

Here is why I have been out of touch - 3 weeks in the mysterious Orient (Turkey) with the family.

Are there any Pantera owners over there?

Istanbul

Herikaya

Cappadocia:

Fetiye:

You would not have believed the roads. We drove 3850 km (about 2400 Miles in 3 weeks).

In all that time, I only saw one cop actually enforcing speed limits. Since we lived there 16 years before, the country has developed an amazing network of roads. I wished I had my car with me. I am not kidding, it really would have been a BLAST to do 2500 miles in a Pantera over there!

Rocky

Are there any Pantera owners over there?

Istanbul

Herikaya

Cappadocia:

Fetiye:

You would not have believed the roads. We drove 3850 km (about 2400 Miles in 3 weeks).

In all that time, I only saw one cop actually enforcing speed limits. Since we lived there 16 years before, the country has developed an amazing network of roads. I wished I had my car with me. I am not kidding, it really would have been a BLAST to do 2500 miles in a Pantera over there!

Rocky

just from the few photos, those three weeks must have been great!

JF - We had a blast. It was an unbelievable adventure.

Rocky

Rocky

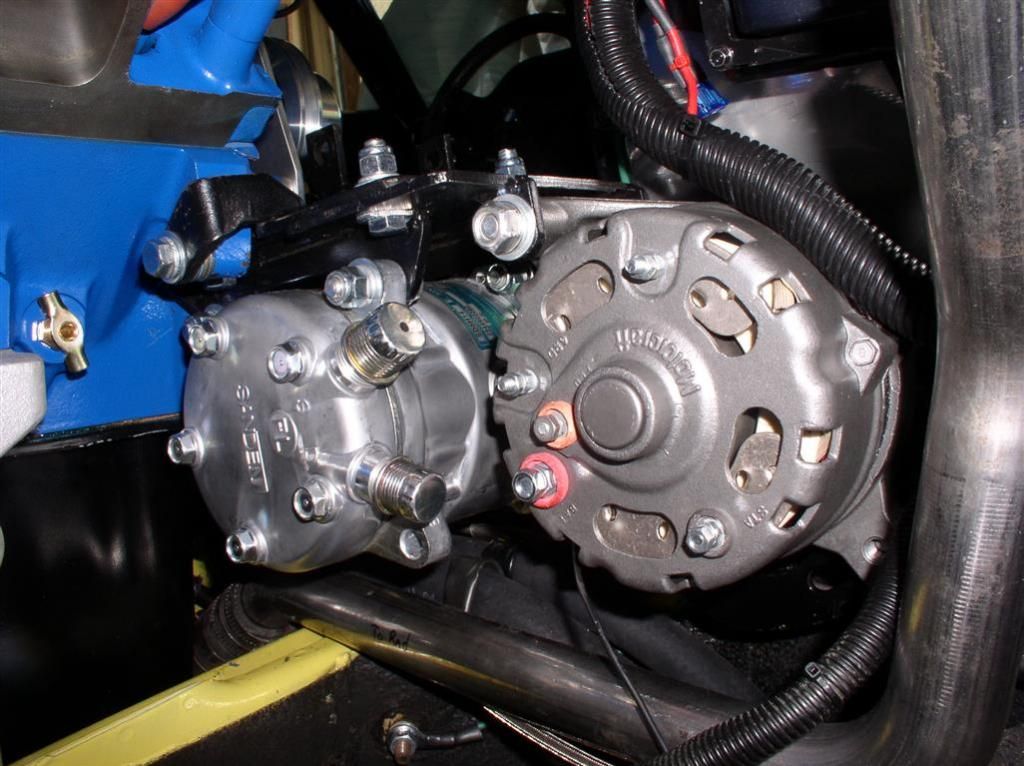

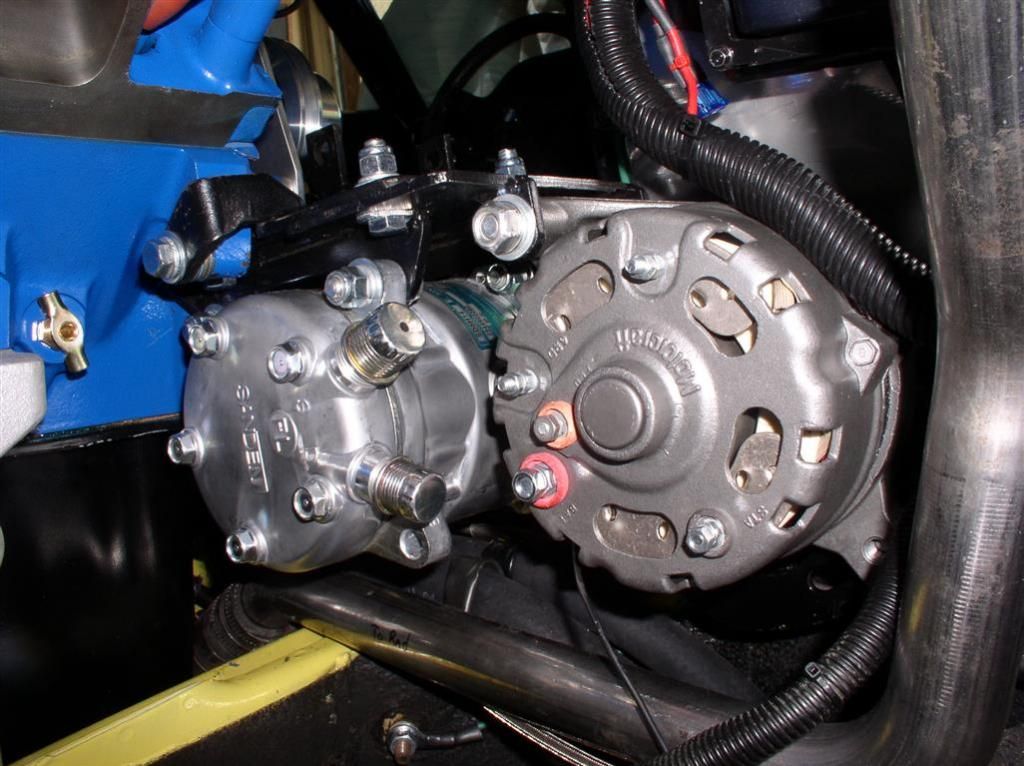

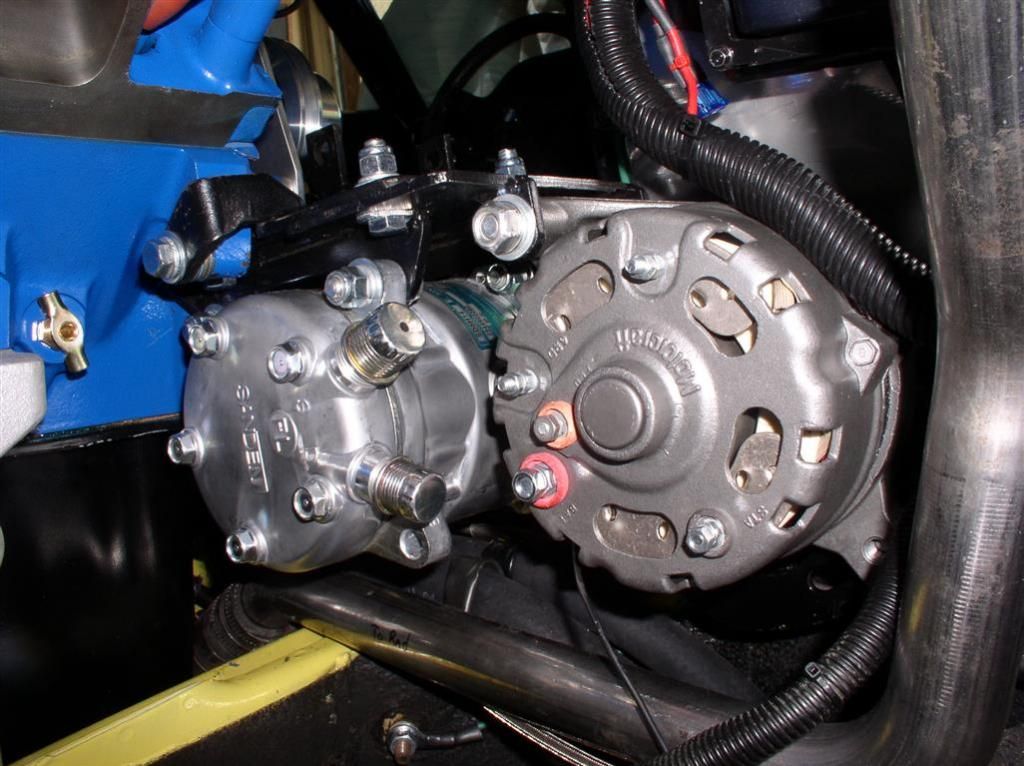

Compressor Bracketry - Fitment & Install

So I have finally got my compressor / alternator bracketry installed. It took a couple of "ins and outs", primarily because of the additional thickness of the extra insulation and the Stainless Steel covers on the rear firewall.

It is the same basic design as the "David Nunn" setup - his is on a Fontana Block, mine is the stock 351 Ford. Here's a link to David's Awesome motor...

Fontana block a/c compressor bracket

My setup is in the car now, and I expect it will stay in there. Things are very tight - I need to be careful of my grounding wires, my heater hoses rubbing on the idler pulley, and the alternator fan rubbing on the SS panel, but it looks like we have solved the major fitment issues, thanks to my buddy Wade (Mark IV / 4280).

Oil Temp Sender

The oil temp sender is in the front of the Avaid 10 Qt pan. It is the standard water temp sender that Neil (my PO) won at a POCA Fun Rally raffle about 6 years ago. It will be wired through the spare switch so I can check oil or water temp on the same gauge.

Bracketry Install

Here's some pictures.

So I have finally got my compressor / alternator bracketry installed. It took a couple of "ins and outs", primarily because of the additional thickness of the extra insulation and the Stainless Steel covers on the rear firewall.

It is the same basic design as the "David Nunn" setup - his is on a Fontana Block, mine is the stock 351 Ford. Here's a link to David's Awesome motor...

Fontana block a/c compressor bracket

My setup is in the car now, and I expect it will stay in there. Things are very tight - I need to be careful of my grounding wires, my heater hoses rubbing on the idler pulley, and the alternator fan rubbing on the SS panel, but it looks like we have solved the major fitment issues, thanks to my buddy Wade (Mark IV / 4280).

Oil Temp Sender

The oil temp sender is in the front of the Avaid 10 Qt pan. It is the standard water temp sender that Neil (my PO) won at a POCA Fun Rally raffle about 6 years ago. It will be wired through the spare switch so I can check oil or water temp on the same gauge.

Bracketry Install

Here's some pictures.

question about your belt drive axuilarries. I can't recall how the original fit and the reason for the offset bump in the bulkhead cover.

so, to be able to reduce the bump to just over engine center line, the belt drives are places low. Is it the slope in the fire wall that allows the pulley/belt not to protrude into the passenger compartment?

so, to be able to reduce the bump to just over engine center line, the belt drives are places low. Is it the slope in the fire wall that allows the pulley/belt not to protrude into the passenger compartment?

JF -

Check out the pictures on page 3 of this thread. You can see the little lip that clearances the belt.

But you are right, the slope of the firewall also provides some clearance.

Check out the pictures on page 3 of this thread. You can see the little lip that clearances the belt.

But you are right, the slope of the firewall also provides some clearance.

Rocky what you might want to do is inserting the long Bolt that holds the Alternator from the rear side. It will be a lot of work to get that thing out if you ever need to change it. Been there done that ;-) In fact the kit I got from Kirk had a welded Nut on the rear side which I drilled the Threads out off to slide the bolt in from that side and put a Nut on the front side.

Jan

Jan

quote:Rocky what you might want to do is inserting the long Bolt that holds the Alternator from the rear side. It will be a lot of work to get that thing out if you ever need to change it. Been there done that ;-) In fact the kit I got from Kirk had a welded Nut on the rear side which I drilled the Threads out off to slide the bolt in from that side and put a Nut on the front side.

Great idea Jan! I'll have to be sure to do that when I reinstall my engine in a few weeks.

Hey Rocky, I see you had to use washers to shim your ac/alt bracket at the block. I had to do this as well when I installed my engine last year in order to get the proper belt alignment.

Here is Rocky having fun working on his Pantera.

Attachments

here is a shot of the inside of the driverside header

Attachments

Note that the picture in Post 106 is the collector BEFORE modifications to a 2 1/2" tube.

We were concerned about the flow restrictions based on the alignment of the collector. It looked pretty bad!

PS> Goodroc - I decided now is the time to make these kind of changes, so I pulled the assembly and will reverse the bolt. Thanks for the tip.

PSS> Garth - On mine, the alignment looked pretty good when I bolt the bracket right up against the engine block with the two 1/2" bolts. I just decided to fill the space in the back with washers so the bracket didn't deform when I tightened it down. But it makes sense that that spacing is there for pulley alignment. You learn something new with every post (and every time I put that bracket in and out!).

PSSS> Garth - good to hear you engine is going back in.. Did you do anything other than fix the bent pushrods/rockers?

Rocky

We were concerned about the flow restrictions based on the alignment of the collector. It looked pretty bad!

PS> Goodroc - I decided now is the time to make these kind of changes, so I pulled the assembly and will reverse the bolt. Thanks for the tip.

PSS> Garth - On mine, the alignment looked pretty good when I bolt the bracket right up against the engine block with the two 1/2" bolts. I just decided to fill the space in the back with washers so the bracket didn't deform when I tightened it down. But it makes sense that that spacing is there for pulley alignment. You learn something new with every post (and every time I put that bracket in and out!).

PSSS> Garth - good to hear you engine is going back in.. Did you do anything other than fix the bent pushrods/rockers?

Rocky

quote:Originally posted by Rocky:

Motor Mounts and Formed Heater Hoses...

The formed hoses are the shizzle for the Pantera application.

[IMG]

http://i1298.photobucket.com/a...dium_zps82c04115.jpg [/url]

Rocky

Where did you buy the 90 degree hoses?

Anders - I just got them at a standard parts store. I just asked the guy behind the counter to find me a pair.

I don't know if you have O'Reilly Auto Parts in your neck of the woods. I have two different hoses (one is slightly shorter than the other). Either will work - it's just the length of the straight end that is different.

Part Numbers are DAYCO 80417 & DAYCO 80418.

Here's a link to one on Amazon:

http://www.amazon.com/Dayco-80...t-Hose/dp/B000C0TE8W

I don't know if you have O'Reilly Auto Parts in your neck of the woods. I have two different hoses (one is slightly shorter than the other). Either will work - it's just the length of the straight end that is different.

Part Numbers are DAYCO 80417 & DAYCO 80418.

Here's a link to one on Amazon:

http://www.amazon.com/Dayco-80...t-Hose/dp/B000C0TE8W

quote:I may want to bend the tubes to bring the swirl tank down so the lip is on the clamp. Recommendations?

You could make a spacer.

What's with the fitting (tee with elbow) on top of what appears to be a PCV valve?

John

The little thing on top of the PCV valve is actually plugged (from the factory), but it allows you to remove the plug.

I am not sure why you might connect your PCV to two sources of vacuum, but that's what it seems to be.

It's nutty!

Thanks for the idea on the Spacer - I am just trying to make things look good, with minimal downtime. Now is the time to bend those tubes down before we fill them with coolant.

I am not sure why you might connect your PCV to two sources of vacuum, but that's what it seems to be.

It's nutty!

Thanks for the idea on the Spacer - I am just trying to make things look good, with minimal downtime. Now is the time to bend those tubes down before we fill them with coolant.

quote:Garth - good to hear you engine is going back in.. Did you do anything other than fix the bent pushrods/rockers?

Replaced all valve springs with new dual valve springs - remember, one of my fancy new beehive springs broke (turned out several were out of spec so much so that I suffered coil bind situation). Had to re-machine the heads, new teflon valve guides, new valve job and additional porting to clean of the newbie mistakes made by the shop that originally ported them, and replaced all the roller rockers (Scorpion warranty replacement) because I discovered that the pushrod was contacting the underside of the rocker body at full lift. I apparently received an OLD box of Scorpion roller rockers that must have sat on the shelf for years (they were silver instead of blue). According to the warranty tech, the old rocker body doesn't have as much clearance to support their advertised lift capacity. The new blue roller rockers have much more clearance.

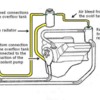

my thoughts on the swirl tank...

even though "thinking" about how I want my coolant is very far down on my list, I am sure I am going to do similair to swirl tank with continous venting.

I'm thinking I want the swirl elevation as low as possible but with the top just above the top of the block elbow. this is where the top of the swirl will be the high point of the block and hopefully the level in the pressure (formerly overflow) tank will also be at the top of the swirl.

even though "thinking" about how I want my coolant is very far down on my list, I am sure I am going to do similair to swirl tank with continous venting.

I'm thinking I want the swirl elevation as low as possible but with the top just above the top of the block elbow. this is where the top of the swirl will be the high point of the block and hopefully the level in the pressure (formerly overflow) tank will also be at the top of the swirl.

Attachments

Great job. I'm enjoying the build.

JF -

The setup I am using, I believe was originally developed by Carroll Smith while working the GT-40 program with another famous Carroll.

http://en.wikipedia.org/wiki/Carroll_Smith

Anyway - the large (Overflow) tank is actually under suction from the water pump. The two inflows at the top are designed to remove air from the radiator and the top of the swirl tank.

Other than that (the Overflow tank plumbing) - it is similar to your drawing.

*** Update: Here is a nice diagram of my setup, taken from one of George's detailed threads. Scroll down to the cooling system part.

GP Sticky on Cooling System Configuration

Java - I am glad you are enjoying it - I am trying to make some progress daily - Hopefully soon we will be driving!

Rocky

The setup I am using, I believe was originally developed by Carroll Smith while working the GT-40 program with another famous Carroll.

http://en.wikipedia.org/wiki/Carroll_Smith

Anyway - the large (Overflow) tank is actually under suction from the water pump. The two inflows at the top are designed to remove air from the radiator and the top of the swirl tank.

Other than that (the Overflow tank plumbing) - it is similar to your drawing.

*** Update: Here is a nice diagram of my setup, taken from one of George's detailed threads. Scroll down to the cooling system part.

GP Sticky on Cooling System Configuration

Java - I am glad you are enjoying it - I am trying to make some progress daily - Hopefully soon we will be driving!

Rocky

Attachments

Thanks for the referance to Carrol Smith. When I get a chance I'll get his books.

I greatly apprecaite your posts and photos

I greatly apprecaite your posts and photos

quote:posted document 'May 25, 2014 06:21 PM'

I updated the Heater Valve Info (Page 6). I would have moved it, but there was other discussion there.

Thanks JF - I figured this is a good way to show off all the stuff we are doing - hopefully, most of it won't be obvious to the casual concourse judge!

Garth - looking forward to another video!

Rocky

quote:Originally posted by Rocky:

Anders - I just got them at a standard parts store. I just asked the guy behind the counter to find me a pair.

I don't know if you have O'Reilly Auto Parts in your neck of the woods. I have two different hoses (one is slightly shorter than the other). Either will work - it's just the length of the straight end that is different.

Part Numbers are DAYCO 80417 & DAYCO 80418.

Here's a link to one on Amazon:

http://www.amazon.com/Dayco-80...t-Hose/dp/B000C0TE8W

Thanks!!

Looks real nice, you want to come do my wiring? Lol last step on my list...

Add Reply

Sign In To Reply