Finally decided to get started on my "Reduced Hump Bulkhead Cover" construction. My plan is to have the center cover attached via Velcro, so I can just pull it off, and access the metal engine cover from inside, without pulling the whole big piece off.

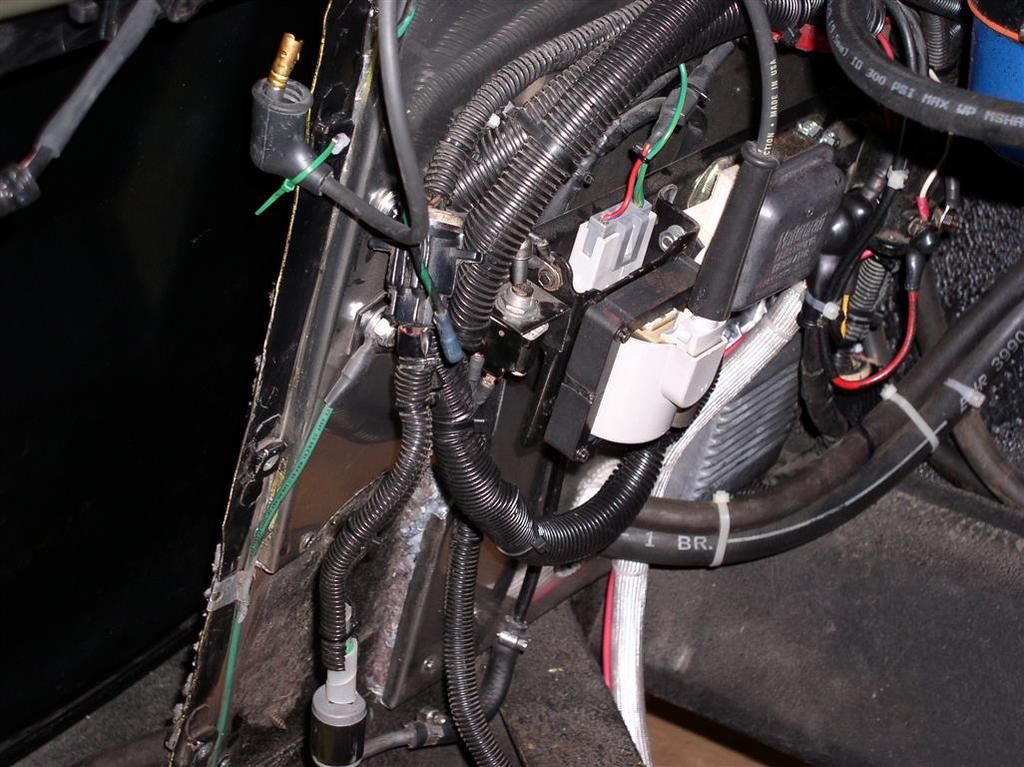

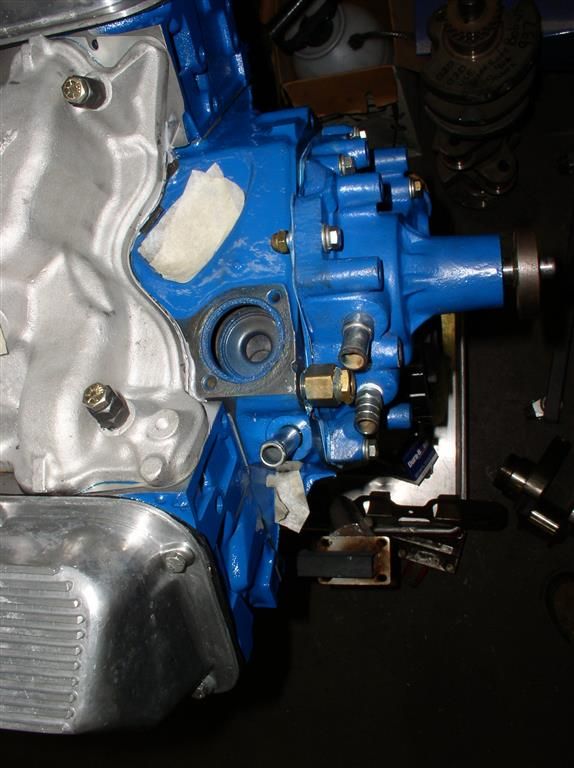

This project will be ongoing until I get a couple more parts for my ZF (on the way), and then will likely go into a holding pattern until I get the motor & transaxle installed.

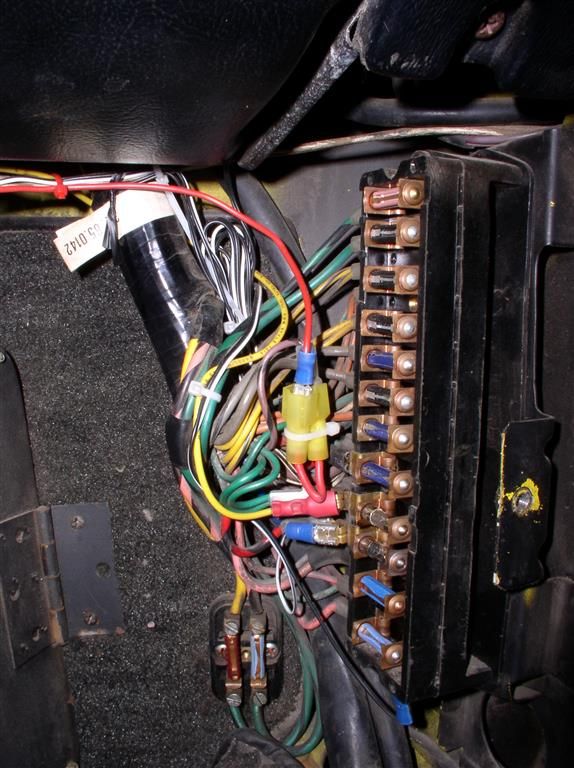

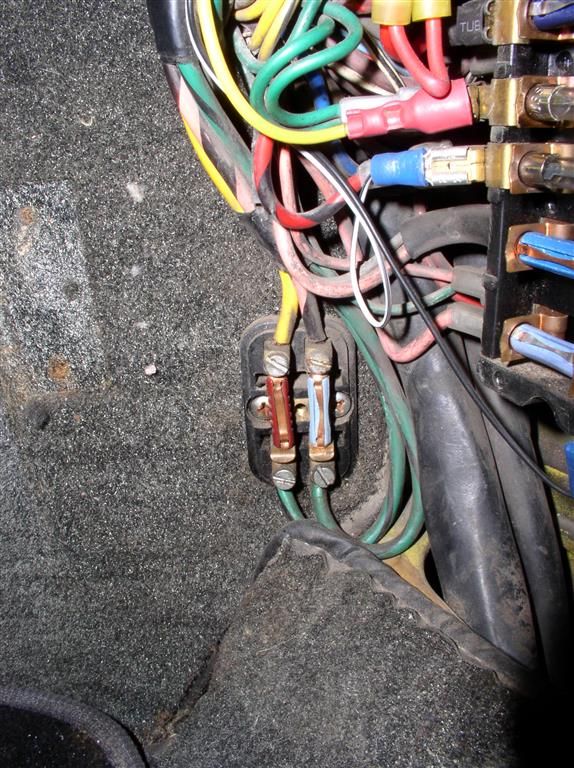

Anyway - I already had the reduced metal engine access cover, and all of the accessories (Sanden Compressor, and 1G alternator outboarded) - this was fabricated on my last build. You can see pictures on about page 4 of this thread.

Now I am starting with a reasonably OK rear bulkhead cover. It had some rips in it, so it would have needed reupholstering anyway.

I stripped off the upholstery and foam, to reveal a fiberglass cover in good shape. I kept the vinyl to match the fabric, and to help me with the sizing when I go to reupholster it.

I plan to do the upholstery on the big pieces (the outside) myself. I will probably take the "hump" part to a professional - maybe. It seems like the hardest part will be sewing the seams accurately.

I stripped off all the foam on the inside and outside, and hit it with a wire brush on my angle grinder. It cleaned up nicely.

Then I cut the center section out with my angle grinder.

I was worried about the thing breaking at the top, so attached a temporary support piece.

This part fits nicely in the car. Now to start on the hump tomorrow (when I can get out and buy some sheet metal and fiberglass resin. Maybe I will look for foam and vinyl at the same time.

Here's couple more pictures in a slideshow.... Watch this space for more pictures.

Slideshow of Reduced Bulkhead Cover Construction.... Rocky