Mike,

How the hay did you get this shaft out of position????

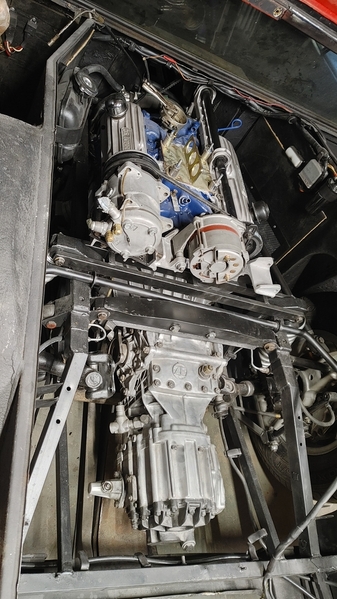

I revisited my pictures, and it looks like I never really took mine out......but I recall doing a dissection of the shifter box.... so I could be lying.....!!! BUt in these two pictures you can see where my shift rods ran, around the shock tower and then back into the inside of the frame to the trans.

That roll pin could be a REAL bugger to tap out and back in without supporting it. Taking the u-joint apart makes me feel more troubled......... I think we determined that the only place to get the u-joints is from some little Italian shop in the middle of nowhere...... I don't recall where....but seems like they are rare AND expensive! So grease it and leave it if at all possible?!

Start with removing the rear piece of the shaft that is adjustable, then remove the trunion retaining nut and lift it up....see if that gives you enuf? If not, then attack the shifter box??

I'm thinking remove the shifter box and strip the shaft out of it....then move the entire shaft forward until you gain enuf clearance to tuck the rear rod back into the frame. then tuck the shaft back in where it should be and reverse!

OK, I found my lie! First two pic's below are before sealer/no-rust paint, where I tied up and wrapped up the errant rear section of shift shaft, but the third pic shows that I succumbed to the need to get the danged thing out of my way, so I MUSTA popped that roll pin out....... Hate when pictures tell me that my mind is developing holes......! You can see just aft of the rubber firewall boot that I had taped off the end of the shaft.

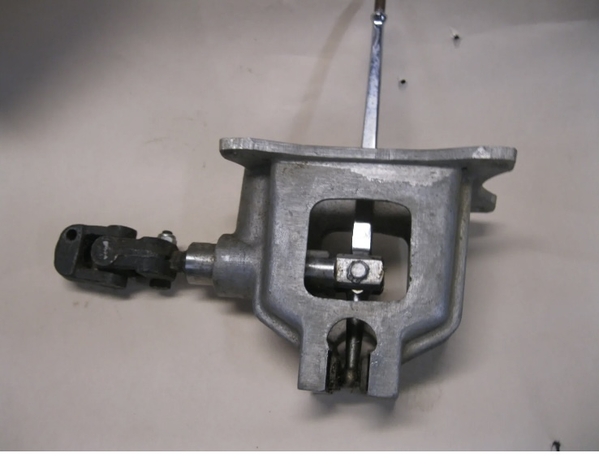

The shifter box is really a "not much to it thing"! We've already determined that it doesn't have as much BS in it as the Pantera shifters. No detentes/balls, no extra springs...

Once the box is out of the way this would have some room to move forwards, but not certain of how much! Certainly it could go rearward and out.....reposition rear shaft etc, reinsert....reverse! NO HAMMERS required!!!

You needed to grease that little ball down at the bottom of the shift lever....right???

Steve