....as for the wheel bearings....

The Ferrari procedure speaks some truth, but final torque is WAY wrong... Since you are using "Mustang/Ford" wheel bearings..... I'd go with that procedure in the Ford books as well!

Pantera procedure is close to what you want to do......butt IMHO way too much subjective feel....and GOING AMISS!

Mutt....... you should really go in and just delete those references in your post. Wouldn't want to mislead anyone....Ferrari or otherwise!

BELOW EDITED 8/14/2024 1PM PST

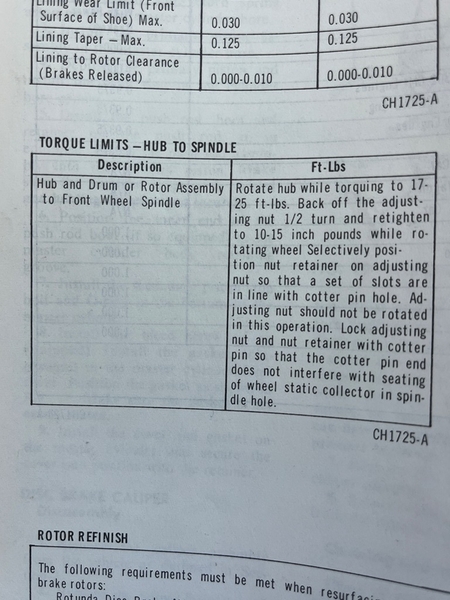

The initial torque tighten 17-25FTLBS WHILE SPINNING THE ROTOR to seat the bearings. Loosen 1/2 turn retighten 10-15 INCH LBS while again spinning... This amounts to pretty much "thumb tight!" Use that new HF inch lb torque wrench rotting in the bottom of your tool box drawer!!!

These are tapered bearings, so they can handle a little preload. 12FT LBs IS TOO HEAVY!!! Would likely burn up the bearings in short order!!!! Don't need that!!!

Wrench on!!!!

Steve

Picture attached from 1970 Ford Shop Manual- Mustangs Cougars etc.