This is an area that I thought had been pretty much determined some time ago with the Dauphine being the winner (donor!). I recall taking my rack apart to see if there was any way to remove any slack in the rack.....and found very little to be able to do!

I think I just greased the Unibal joints, slapped on new rubber booties, packed the whole thing with some new grease and put the cover back on! A pretty hardy box if I may say so!

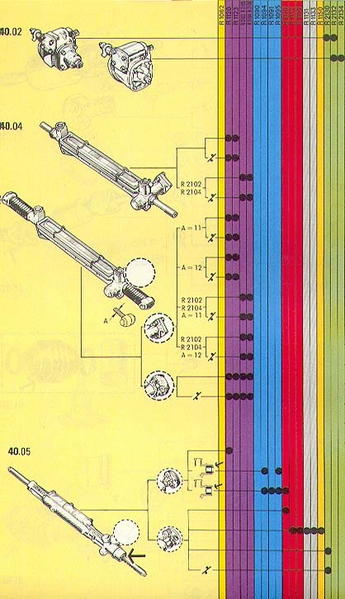

Here is where it get's dicey. Denis mentioned simply going to the bearing house with his parts in hand and coming home with new parts! While tie rod end may be true (Fiat part according to the parts book...... probably posted elsewhere on this site, but I don't have it handy(!) but in most cars, the Unibal joint was a very custom piece!

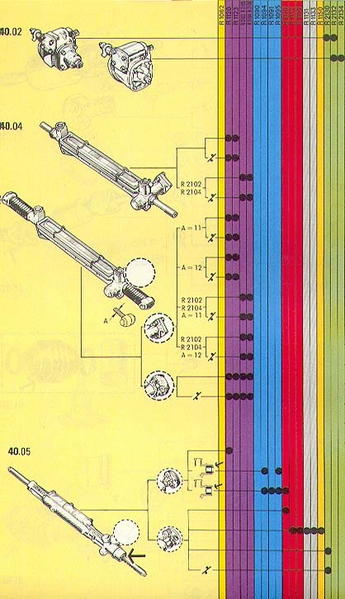

The rack center shaft may have been modified (shortened?) when compared to the stock Dauphine parts. I think it was modified to accept threaded Unibal (14? or 16) joints. That would be a MODIFIED Unibal joint where the threaded shaft section was turned down and rethreaded! (Likely why I greased mine and put new covers on....and called it! Actually the Unibals were in great shape and weren't loose and rattley like the a-arm ends!) (so glad for this!!)

You are not going to walk into a dealer anywhere and find these Unibal joints.

Denis, If you can post pics of your later version with bearings (where do they go? and how?) I think that would help some...... Cuz it sounds different....? Is yours a clamp in version (round clamps over body?)

Back to the original question, I think the "kit" would possibly work for the booties and the rag joint. The rest of the parts are a mystery.

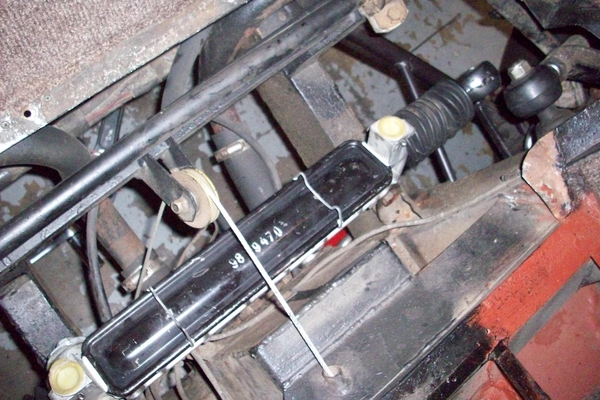

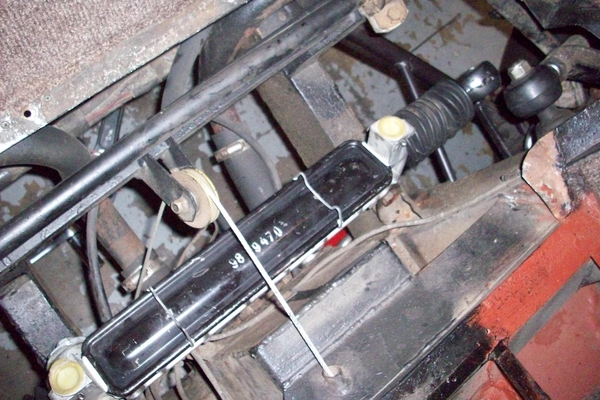

Here are a couple of photos, but I must advise that they are not the best and I was lacking the foresight to take more pic's of the rack deshrouded!!!! Duh!

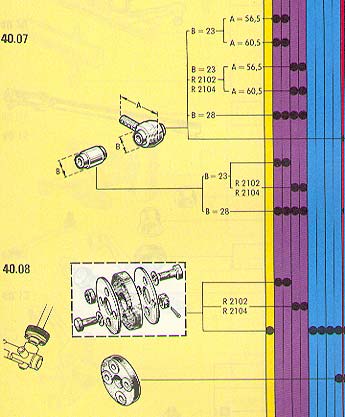

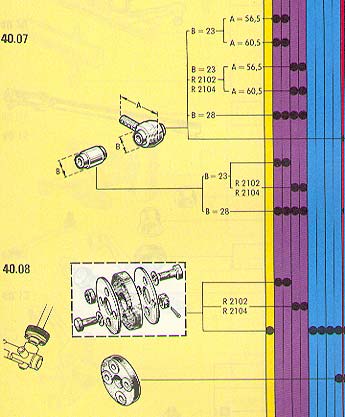

I added pic's of the frame mounts for this style of rack. It appears that there is a needle bearing on the steering shaft.... I don't recall what the shaft rode in, in the housing. Didn't seem like much at all....perhaps right on the aluminium?

There may have been some tensioning wipers under those towers that appear on either side of the cover. Again, my apologies for not using more bits in the camera to catch this stuff!!!! Someone, please fill in my blanks!

Cheers! Steve

![]() ) ...

) ...